SHAFT MOUNTED ROCKER ARMS

+22

Curt

steven gregoire

bruno

Nevs

powerstrokeace

John Myrick

rmcomprandy

DanH

BigDave65

Doug Rahn

CDMBill

cletus66

Paul Kane

Scott Foxwell

dfree383

Wheelie58

schmitty

95lightiningguy

138

cool40

Lem Evans

c.evans

26 posters

Page 1 of 4

Page 1 of 4 • 1, 2, 3, 4

SHAFT MOUNTED ROCKER ARMS

SHAFT MOUNTED ROCKER ARMS

Shaft mounted rockers.

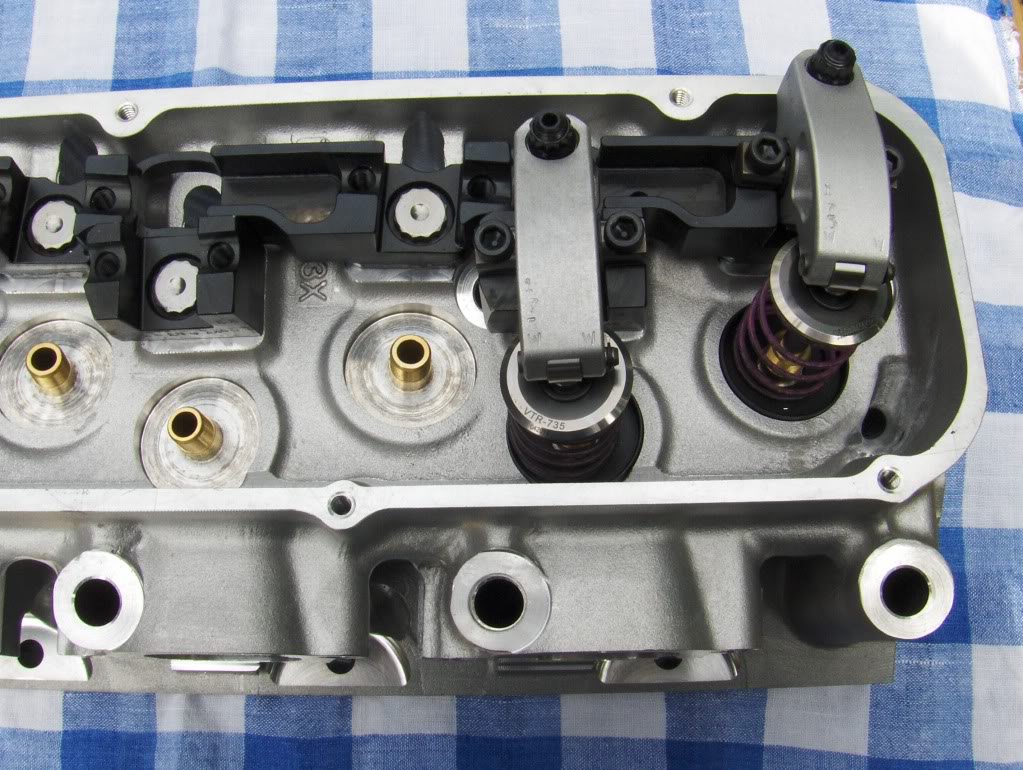

The picture above is of W.W. rockers on a Pro-Filer 205 head. This is showing the correct geometry pattern with the valve closed and the roller to the inside a little bit.

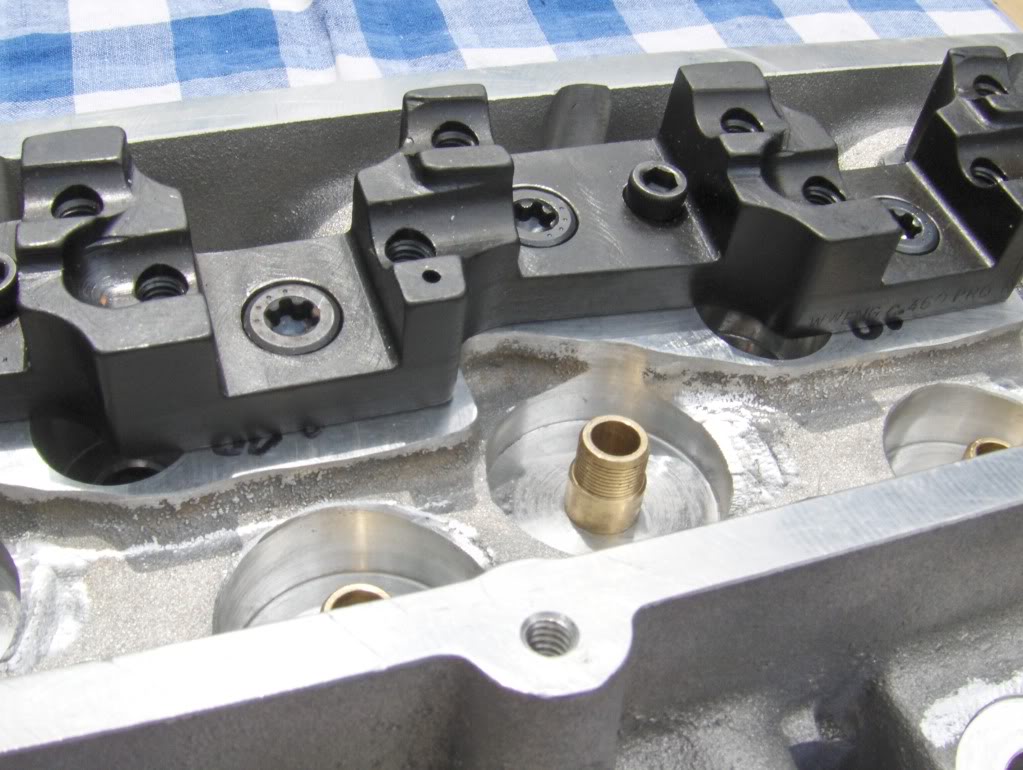

The above picture shows the bottom side up of a Pro-Filer 205 one piece stand which is flat and in the background the bottom side of the new one piece stand for the TFS A-460 BBF3X head. Notice how the cant angle has to be incoorporated into the stand. So the one piece stand is for the intakes only. The exhaust stands are 4 individual stands that butt up against the long intake stand.

This is a bottom side view of the Pro-Filer 205 in the foreground, and then the bottom side view of the new W.W. A-460 rockers in the background. You can see where the 4 exhaust stands are relieved to clear the head studs (shiny area).

W.W. Engineering A-460 rocker arms. They are 3D profiled, shot peened, and the nose lightened to reduce the polar moment of inertia.

Just another view of the bottom side of the stands. The C-460, Pro-Filer 205, and Thor heads will all be flat across the bottom, because they are designed for shaft mounted rockers only from the get-go. In the background are the A-460 stands. The big improvement is that we have gotten away from 16 individual stands, which is something that Lem and several of us have been requesting for a long time. With the A-460 stands we have a compound cant angle situation, because the heads of course are designed to use stud mounted rocker arms and a stud girdle. So shaft mounted rocker arms are not for everybody, but if you need them, then I feel we have made an upgrade in the design here with the new W.W. stuff. Notice the lettering on the stands. With the W.W. pieces, the lettering will always face towards the exhaust port side of the head.

This is a top side view of the stands. The new A-460 stand is in the background.

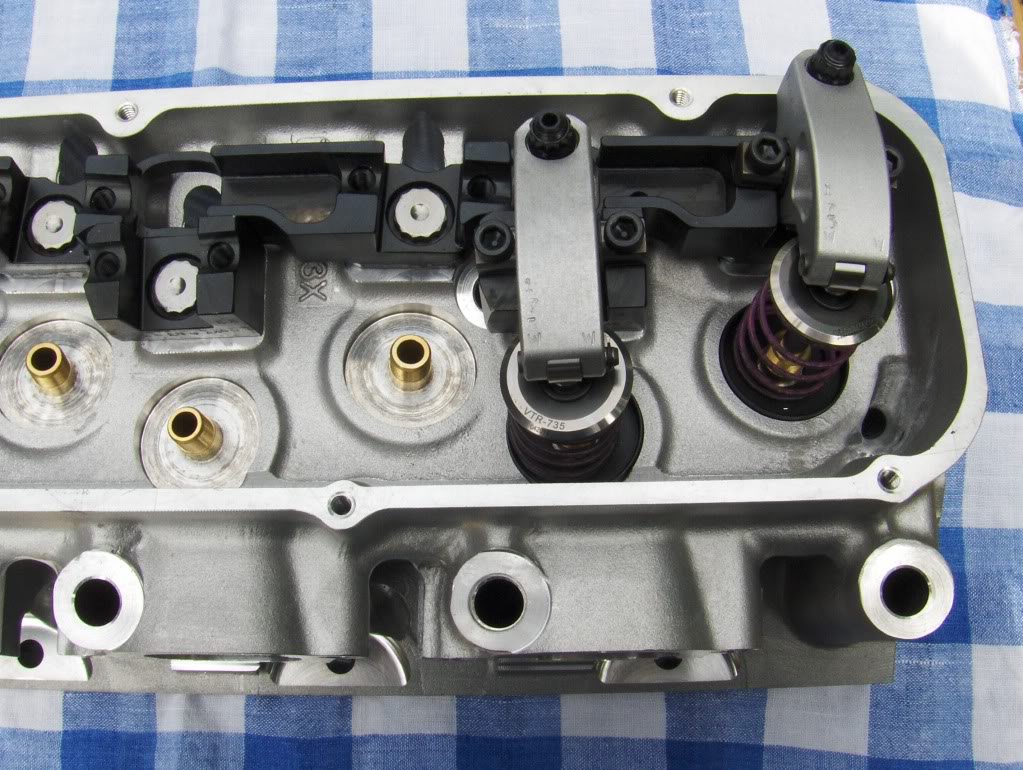

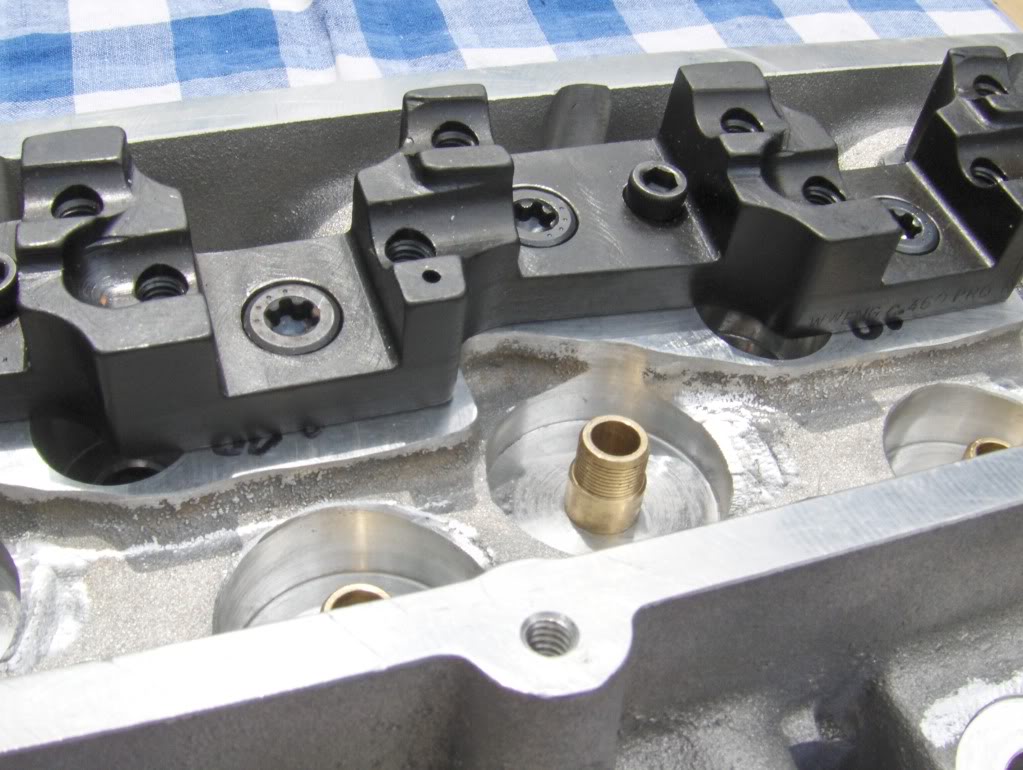

The new TFS A-460, 18 bolt, BBF3X version of the heads, with the squared up rocker stud bosses. We can thank TFS for sending a head down to Wilfred for him to work on this project, which has taken a few months.

Great view here. Those are 12 pt. ARP bolts holding the stands down. To improve the holding force of the exhaust stud, TFS has increased to depth of the threaded hole to like 1.250", so Lem came over and determined that the exhaust bolt could be a total of 1.500" long and we would still get full thread engagement. I will try to get Wilfred to include longer exhaust bolts (ARP 12 pt.) in the future. You can also see the "X" on the new head casting.

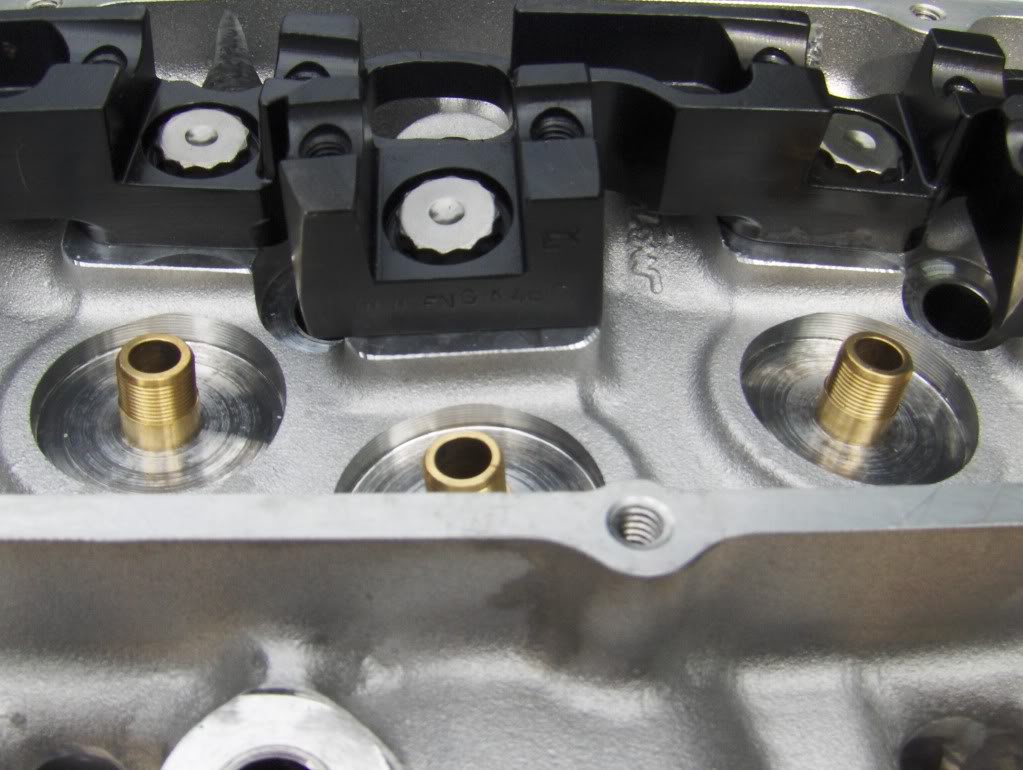

Here you see the 3X on the new TFS casting and you can see the elongated pushrod slots, which is something we have had in the 18 bolt casting since 2005 I think.

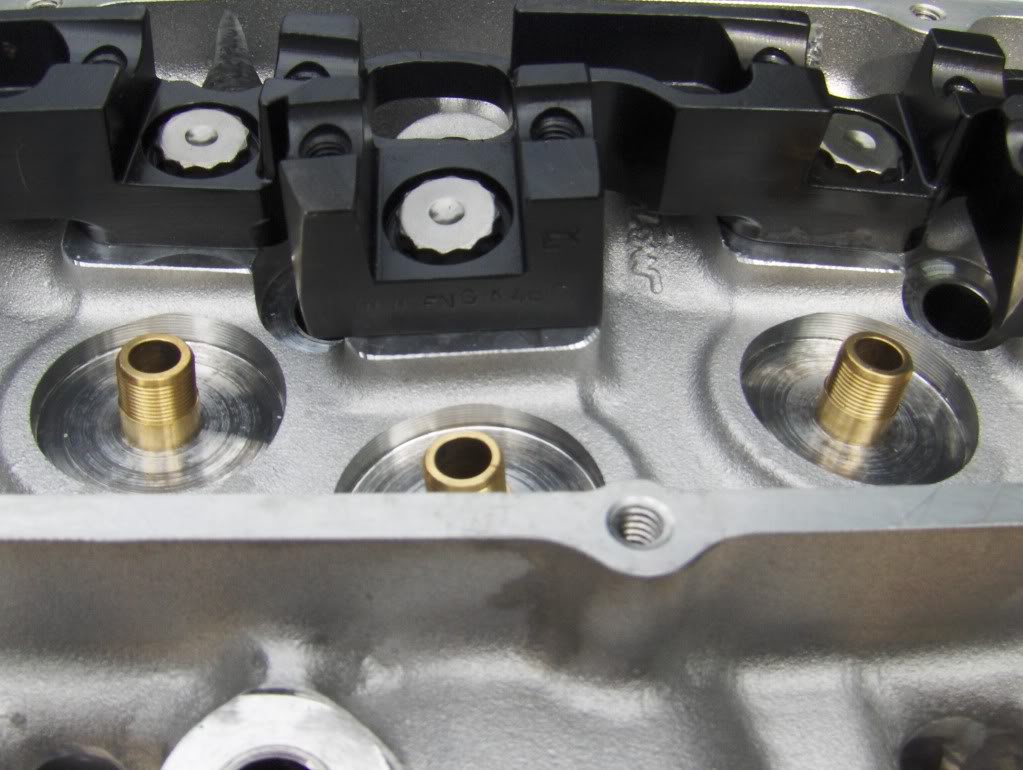

This is the Pro-Filer stand and it is important that all engine builders notice this. On heads that have CNC machined rocker bolt holes, such as the C-460, the Pro-Filer, and others,,,, it is important that you bottom tap all bolt holes. (The TFS A-460 heads have rolled threads, which are stronger.) Notice the 2 bolts under the intake rocker. The right hand bolt won't go all the way down, because it needs to be bottom tapped.

This view shows how the exhaust stands butt up against the one piece intake bar/stand. AFTER all of your fitting, shimming and mock up, you could tig weld the exhaust stands to the intake stand. OR the right hand rocker arm hold down bolt, could be tapped into the square pad, with a much longer 5/16" bolt going all the way through and into the head. Of course you would have to etch mark the stand and always put it back in the same spot.

Good view showing the slotted pushrod holes. We increased the body length of the rocker arm, and when you do that, your pushrod holes must move up towards the intake manifold. I'm always having to slot the pushrod holes in EX 514 head for example for the truck pullers that run then with shaft mounted rocker arms and turn 8500-9000 rpm.

The picture above is of W.W. rockers on a Pro-Filer 205 head. This is showing the correct geometry pattern with the valve closed and the roller to the inside a little bit.

The above picture shows the bottom side up of a Pro-Filer 205 one piece stand which is flat and in the background the bottom side of the new one piece stand for the TFS A-460 BBF3X head. Notice how the cant angle has to be incoorporated into the stand. So the one piece stand is for the intakes only. The exhaust stands are 4 individual stands that butt up against the long intake stand.

This is a bottom side view of the Pro-Filer 205 in the foreground, and then the bottom side view of the new W.W. A-460 rockers in the background. You can see where the 4 exhaust stands are relieved to clear the head studs (shiny area).

W.W. Engineering A-460 rocker arms. They are 3D profiled, shot peened, and the nose lightened to reduce the polar moment of inertia.

Just another view of the bottom side of the stands. The C-460, Pro-Filer 205, and Thor heads will all be flat across the bottom, because they are designed for shaft mounted rockers only from the get-go. In the background are the A-460 stands. The big improvement is that we have gotten away from 16 individual stands, which is something that Lem and several of us have been requesting for a long time. With the A-460 stands we have a compound cant angle situation, because the heads of course are designed to use stud mounted rocker arms and a stud girdle. So shaft mounted rocker arms are not for everybody, but if you need them, then I feel we have made an upgrade in the design here with the new W.W. stuff. Notice the lettering on the stands. With the W.W. pieces, the lettering will always face towards the exhaust port side of the head.

This is a top side view of the stands. The new A-460 stand is in the background.

The new TFS A-460, 18 bolt, BBF3X version of the heads, with the squared up rocker stud bosses. We can thank TFS for sending a head down to Wilfred for him to work on this project, which has taken a few months.

Great view here. Those are 12 pt. ARP bolts holding the stands down. To improve the holding force of the exhaust stud, TFS has increased to depth of the threaded hole to like 1.250", so Lem came over and determined that the exhaust bolt could be a total of 1.500" long and we would still get full thread engagement. I will try to get Wilfred to include longer exhaust bolts (ARP 12 pt.) in the future. You can also see the "X" on the new head casting.

Here you see the 3X on the new TFS casting and you can see the elongated pushrod slots, which is something we have had in the 18 bolt casting since 2005 I think.

This is the Pro-Filer stand and it is important that all engine builders notice this. On heads that have CNC machined rocker bolt holes, such as the C-460, the Pro-Filer, and others,,,, it is important that you bottom tap all bolt holes. (The TFS A-460 heads have rolled threads, which are stronger.) Notice the 2 bolts under the intake rocker. The right hand bolt won't go all the way down, because it needs to be bottom tapped.

This view shows how the exhaust stands butt up against the one piece intake bar/stand. AFTER all of your fitting, shimming and mock up, you could tig weld the exhaust stands to the intake stand. OR the right hand rocker arm hold down bolt, could be tapped into the square pad, with a much longer 5/16" bolt going all the way through and into the head. Of course you would have to etch mark the stand and always put it back in the same spot.

Good view showing the slotted pushrod holes. We increased the body length of the rocker arm, and when you do that, your pushrod holes must move up towards the intake manifold. I'm always having to slot the pushrod holes in EX 514 head for example for the truck pullers that run then with shaft mounted rocker arms and turn 8500-9000 rpm.

Last edited by c.evans on June 27th 2011, 12:16 am; edited 10 times in total

c.evans- BBF VENDOR SPONSOR

- Posts : 2260

Join date : 2008-12-03

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

Can the Torx + bolts as seen on the 205 heads be used on the A460 heads?

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

nice looken rockers Charlie!

cool40- BBF CONTRIBUTOR

- Posts : 7313

Join date : 2009-08-31

Age : 53

Location : on the 1/8 mile dyno

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

Looks great but not sure them springs are up to the task.

95lightiningguy- Posts : 570

Join date : 2009-12-09

Age : 53

Location : N. Little Rock AR

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

95lightiningguy wrote:Looks great but not sure them springs are up to the task.

I was thinking the same thing.

schmitty- Posts : 4538

Join date : 2008-12-02

Age : 54

Location : Holdrege, NE

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

he must be planning on a hyd flat deal.those springs should'nt hurt it.

cool40- BBF CONTRIBUTOR

- Posts : 7313

Join date : 2009-08-31

Age : 53

Location : on the 1/8 mile dyno

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

Nice detailed pics. Most guys wont even take a picture of their shafts, much less post them on the internet!

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

Thanks Keith,

Up until now I have never posted a picture of anything on the internet, because I am a "dummy". It took a lot of work on Livermore Dave's part, along with big help from Lem to get those pictures posted. Thanks Dave & Lem.

It took a lot of work on Livermore Dave's part, along with big help from Lem to get those pictures posted. Thanks Dave & Lem.

I have a nice digital camera that I have learned how to use, and have got hundreds of pictures of heads and manifolds that I would like to post, because I believe it would be educational for the guys. Maybe I can do better in the future.

Charlie

Up until now I have never posted a picture of anything on the internet, because I am a "dummy".

I have a nice digital camera that I have learned how to use, and have got hundreds of pictures of heads and manifolds that I would like to post, because I believe it would be educational for the guys. Maybe I can do better in the future.

Charlie

c.evans- BBF VENDOR SPONSOR

- Posts : 2260

Join date : 2008-12-03

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

cool40 wrote:he must be planning on a hyd flat deal.those springs should'nt hurt it.

Those are the New Lemalloy-69 valve springs.......

Awsome Post Charlie. If you need help opening a photo bucket account give me a ring.

dfree383- BBF CONTRIBUTOR

- Posts : 14846

Join date : 2009-07-09

Location : Home Wif Da Wife.....

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

Wheelie58 wrote:Nice detailed pics. Most guys wont even take a picture of their shafts, much less post them on the internet!

Now you know where you can get the shaft

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

Great pics and good write up. I've never been a fan of individual stand shaft systems. IMO they don't have any where near the support/stability as a good stug/girdle set up. This is a great improvement for the A460 head. Will these work on an early set?

I sure like TF's castings...make Profilers look like high school shop projects.

I sure like TF's castings...make Profilers look like high school shop projects.

Scott Foxwell- Posts : 419

Join date : 2011-06-23

Age : 66

Location : E Tennessee

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

dfree383 wrote:

Those are the New Lemalloy-69 valve springs.......

What are the spec's on those compared to the Lemmungus 96 spring?

schmitty- Posts : 4538

Join date : 2008-12-02

Age : 54

Location : Holdrege, NE

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

Excellent pictures. Keep 'em coming.

cletus66- Posts : 865

Join date : 2009-08-08

Age : 58

Location : Charles City, Virginia

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

Scott Foxwell wrote:Great pics and good write up. I've never been a fan of individual stand shaft systems. IMO they don't have any where near the support/stability as a good stug/girdle set up. This is a great improvement for the A460 head. Will these work on an early set?

I sure like TF's castings...make Profilers look like high school shop projects.

really?

138- Posts : 1593

Join date : 2009-08-19

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

i took a few of the WW's Charlie got for me,same thing he's got in the pic's but on eliminator head.Charlie had these made to be a "bolt on"for TFS 18 bolt heads so i thought i'd run into problems.  but i only had to take a little off at the intake runner.a few minutes of work and they're on! these are some quality rockers!

but i only had to take a little off at the intake runner.a few minutes of work and they're on! these are some quality rockers!

cool40- BBF CONTRIBUTOR

- Posts : 7313

Join date : 2009-08-31

Age : 53

Location : on the 1/8 mile dyno

Clearance for stud and nut under shaft mount

Clearance for stud and nut under shaft mount

On my older A-460 castings we had to grind the top of the stud and the 12 point nut to fit under the Jessel shaft mounts. Is that potentially the case with the WW's?

CDMBill- Posts : 182

Join date : 2010-08-09

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

CDMBill wrote:On my older A-460 castings we had to grind the top of the stud and the 12 point nut to fit under the Jessel shaft mounts. Is that potentially the case with the WW's?

The studs are longer than they need to be.........so the potential is there.

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

what about bolts? can you even get a bolt in an A460 head?Lem Evans wrote:CDMBill wrote:On my older A-460 castings we had to grind the top of the stud and the 12 point nut to fit under the Jessel shaft mounts. Is that potentially the case with the WW's?

The studs are longer than they need to be.........so the potential is there.

cool40- BBF CONTRIBUTOR

- Posts : 7313

Join date : 2009-08-31

Age : 53

Location : on the 1/8 mile dyno

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

i've heard some say they dont like studs,so.............Lem Evans wrote:Sure one could........depends on the design.

cool40- BBF CONTRIBUTOR

- Posts : 7313

Join date : 2009-08-31

Age : 53

Location : on the 1/8 mile dyno

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

So....what is the question?

Who is they?

A good well designed bolt would be great in my book.

Who is they?

A good well designed bolt would be great in my book.

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

arp or anybody make one? hell i'd use a bolt before i give damn near 300$ for studs and then go to cut'n on them.lolLem Evans wrote:So....what is the question?

Who is they?

A good well designed bolt would be great in my book.

cool40- BBF CONTRIBUTOR

- Posts : 7313

Join date : 2009-08-31

Age : 53

Location : on the 1/8 mile dyno

Re: SHAFT MOUNTED ROCKER ARMS

Re: SHAFT MOUNTED ROCKER ARMS

Guys here's the deal. On just about all A-460, B-460, C-460, Pro-Filers, E-460 heads and so on,,, when you are running head studs, you need to double check the clearance between the stud and the underside of your shaft mounted rockers stands. For years we've had to shorten those inner head studs and/or thin the 12 pt. nuts. True story,,,, just recently Phillip Oakley got a C-460 headed engine in here to rebuild, and some "expert engine builder" left the inner row of head studs standing way too tall, and then had bolted down the W.W. Engineering rocker stands and sent the engine out the door that way. In the process he ruined the rocker stands and some rocker arms. The bottom of the stands was bent like a horseshoe, because the end was resting on the long head stud.

Furthermore, as mentioned in the Ford Racing directions for the C-460 heads, Ford suggests that you use the B&B step shouldered washers to help prevent the bolt boss from pinching down/inward with the 140 ft.lbs. of torque that you put on the 9/16" studs. So we counterbore all the bolt bosses about .125" deeper in order to install the step shouldered washers. Stefs/B&B make a tool for doing this machining operation.

To compound the problem even more, ever since ARP has added the "internal wrenching" feature to their head studs, they have made them even longer than the old specs, and now you have to cut off a bunch of threads.

So the bottom line is that the engine builder should be smart enough to always check for clearance between the rocker stands and head studs, including washers and nuts. Another area to check for clearance is between the stands and the valve springs and retainers.

Hope this helps,

Charlie

Furthermore, as mentioned in the Ford Racing directions for the C-460 heads, Ford suggests that you use the B&B step shouldered washers to help prevent the bolt boss from pinching down/inward with the 140 ft.lbs. of torque that you put on the 9/16" studs. So we counterbore all the bolt bosses about .125" deeper in order to install the step shouldered washers. Stefs/B&B make a tool for doing this machining operation.

To compound the problem even more, ever since ARP has added the "internal wrenching" feature to their head studs, they have made them even longer than the old specs, and now you have to cut off a bunch of threads.

So the bottom line is that the engine builder should be smart enough to always check for clearance between the rocker stands and head studs, including washers and nuts. Another area to check for clearance is between the stands and the valve springs and retainers.

Hope this helps,

Charlie

Last edited by c.evans on June 29th 2011, 8:38 am; edited 1 time in total

c.evans- BBF VENDOR SPONSOR

- Posts : 2260

Join date : 2008-12-03

Page 1 of 4 • 1, 2, 3, 4

Similar topics

Similar topics» Shaft mounted rockers C-460 picking order/recommendations

» COMP Cams 841-16 Endure-X, Sheet metal valve cover, Ultra Pro Magnum roller rockers

» ? about rocker arms

» Crane roller rockers new price SOLD

» Rocker arms ?

» COMP Cams 841-16 Endure-X, Sheet metal valve cover, Ultra Pro Magnum roller rockers

» ? about rocker arms

» Crane roller rockers new price SOLD

» Rocker arms ?

Page 1 of 4

Permissions in this forum:

You cannot reply to topics in this forum|

|

|