521 cid broken camshaft dowel for timing gear . bent valves

+7

Lem Evans

rmcomprandy

lance flake

norm

Dave De

supervel45

maverick172

11 posters

Page 4 of 5

Page 4 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

I ended up cutting my rings 30/30 on a 4.42" bore. Have not run it yet and am in no hurry to with the way the economy is going. One of the reasons I cut them the same is because I am old school and NOS rings in the past always had more gap on the top ring. That's just me though and I don't worry about .002" causing ring flutter and all that. Oh and another thing the top ring is Molly Coated and the Second Ring is Cast/Plain, it will probably find it own bigger gap in short order running.

If the carburetor is Too Small CFM wise, the engine will not get to Zero vacuum at wide open throttle (WTO) at full RPM..

Power valves are N/O or normally open valve in the fuel circuit, when the engine is not running.

When vacuum is applied they/it close/s and stops fuel flow enrichment of the main circuit, so that fuel though the main Jet/Circuit is less, leaning out the engine during cruise conditions for better fuel mileage and emissions.

When the throttle is opened, engine vacuum falls, the power valve opens, and the fuel mixture is enriched.

On the lean out part at WOT at full RPM, Let's just say This. If you have an engine that is even close to 2.5hg, you do not want a 2.5hg power valve. It may not be what Holley rated it at for one, for two it can partially close and lean out the main circuit.

Here is a article on the subject. I did not read it all of check it for errors.

https://www.enginelabs.com/engine-tech/carb-science-series-holley-power-valves-explanation-and-tuning/

I think Dave's point on the 4 blue tipped rocker arms may show that those cylinders where clipping the most, if that actually is what has happened when you get your new valves, and mock it up.

That does not mean you should Forgo Checking your top end oiling, by any means. while it's apart.

Be careful cutting those reliefs, and make sure you get them right.

If the carburetor is Too Small CFM wise, the engine will not get to Zero vacuum at wide open throttle (WTO) at full RPM..

Power valves are N/O or normally open valve in the fuel circuit, when the engine is not running.

When vacuum is applied they/it close/s and stops fuel flow enrichment of the main circuit, so that fuel though the main Jet/Circuit is less, leaning out the engine during cruise conditions for better fuel mileage and emissions.

When the throttle is opened, engine vacuum falls, the power valve opens, and the fuel mixture is enriched.

On the lean out part at WOT at full RPM, Let's just say This. If you have an engine that is even close to 2.5hg, you do not want a 2.5hg power valve. It may not be what Holley rated it at for one, for two it can partially close and lean out the main circuit.

Here is a article on the subject. I did not read it all of check it for errors.

https://www.enginelabs.com/engine-tech/carb-science-series-holley-power-valves-explanation-and-tuning/

I think Dave's point on the 4 blue tipped rocker arms may show that those cylinders where clipping the most, if that actually is what has happened when you get your new valves, and mock it up.

That does not mean you should Forgo Checking your top end oiling, by any means. while it's apart.

Be careful cutting those reliefs, and make sure you get them right.

supervel45- Posts : 4498

Join date : 2013-09-04

maverick172 likes this post

rocker arms pics and 1 exhaust vale picture added

rocker arms pics and 1 exhaust vale picture added

Last edited by maverick172 on May 19th 2023, 7:06 am; edited 1 time in total

maverick172- Posts : 205

Join date : 2022-10-16

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

ya that is were i am going with this engine i looked at my mahle ring sheet and in extreme supercharged and nos applications it is the same cut top and bottom ring .007 per inch 150shot nos i think showed .006 top and .007 bottom so puts me right in the pocket, at 28/30 .

ya i read up on power valves i understand about how they work now , totally makes sense cause i am pretty sure this engine only makes like 4 or 5 on the vaccum if memory serves me i used it to tune my idele circuit .

kinda off odd that holley uses something to control part of the wide open throttle circuit to be vaccum operated . but i did not engineer .

ya i read up on power valves i understand about how they work now , totally makes sense cause i am pretty sure this engine only makes like 4 or 5 on the vaccum if memory serves me i used it to tune my idele circuit .

kinda off odd that holley uses something to control part of the wide open throttle circuit to be vaccum operated . but i did not engineer .

supervel45 wrote:I ended up cutting my rings 30/30 on a 4.42" bore. Have not run it yet and am in no hurry to with the way the economy is going. One of the reasons I cut them the same is because I am old school and NOS rings in the past always had more gap on the top ring. That's just me though and I don't worry about .002" causing ring flutter and all that. Oh and another thing the top ring is Molly Coated and the Second Ring is Cast/Plain, it will probably find it own bigger gap in short order running.

If the carburetor is Too Small CFM wise, the engine will not get to Zero vacuum at wide open throttle (WTO) at full RPM..

Power valves are N/O or normally open valve in the fuel circuit, when the engine is not running.

When vacuum is applied they/it close/s and stops fuel flow enrichment of the main circuit, so that fuel though the main Jet/Circuit is less, leaning out the engine during cruise conditions for better fuel mileage and emissions.

When the throttle is opened, engine vacuum falls, the power valve opens, and the fuel mixture is enriched.

On the lean out part at WOT at full RPM, Let's just say This. If you have an engine that is even close to 2.5hg, you do not want a 2.5hg power valve. It may not be what Holley rated it at for one, for two it can partially close and lean out the main circuit.

Here is a article on the subject. I did not read it all of check it for errors.

https://www.enginelabs.com/engine-tech/carb-science-series-holley-power-valves-explanation-and-tuning/

I think Dave's point on the 4 blue tipped rocker arms may show that those cylinders where clipping the most, if that actually is what has happened when you get your new valves, and mock it up.

That does not mean you should Forgo Checking your top end oiling, by any means. while it's apart.

Be careful cutting those reliefs, and make sure you get them right.

maverick172- Posts : 205

Join date : 2022-10-16

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Your Carter and Quadra Jets Metering Rods Run off vacuum to mostly, QJet has a mechanical lift off the secondary air door though for the rods.

I would set that Dominator up for Track only, likely without a power valve for less tuning headache and things to go wrong. The Diaphragm on the Power Valve can leak, and it goes straight into the engine and richens up the fuel mixture and it may be small enough not to even notice.

Get a 750 or 800 Holley DP for the Street. Not a 850 or 950 or 1,000. They are much bigger fuel pigs in by experience. I am not going to go into them here but, it's enough to turn me off in a dual mode of street and track use of the big 4150's. Get a used 4779 or 4780 Holley and play with that. If that 950 worked good on the 501, it is another good reason not to monkey with it.

An always oil your threads so they don't wear out as fast, Holley love to strip screws.

I would also recommend you throw the Wide Band at the track out, or at least until you get a lot of carb tuning experience and a high dollar one that is accurate.

I see guys trying to street tune these Holley's with them, looking to get computer fuel injection numbers at all loads and rpms, just wear the screws out chasing their tail.

Check your manifold at steady cruise speed in high gear, before you make any power valve decisions on sizing.

If Holley started making 1Hg valves, that's Retarded. 2.5Hg was as low as they used to sell, and I would not be suprized if their was not a time when 3.5Hg was.

When you tune your idle screws make sure the engine is at full operating temperature. When you get highest vacuum, move the a little more each way and see if rpm increases or the engine smooths out any. After you do them long enough you get a better feel for doing it that way I guess.

My Hastings ring instructions were about the same as yours, wanted less gap on the top. All old shop manuals all my life just the opposite. I get it on Pro level engines that come apart all the time for refresh.

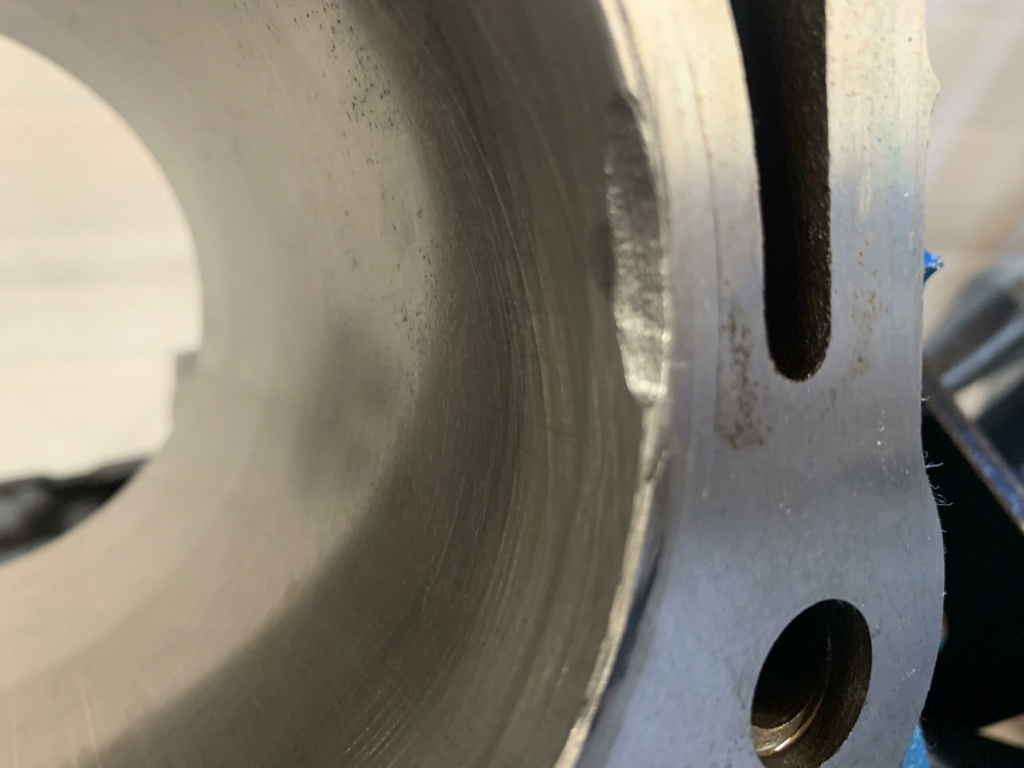

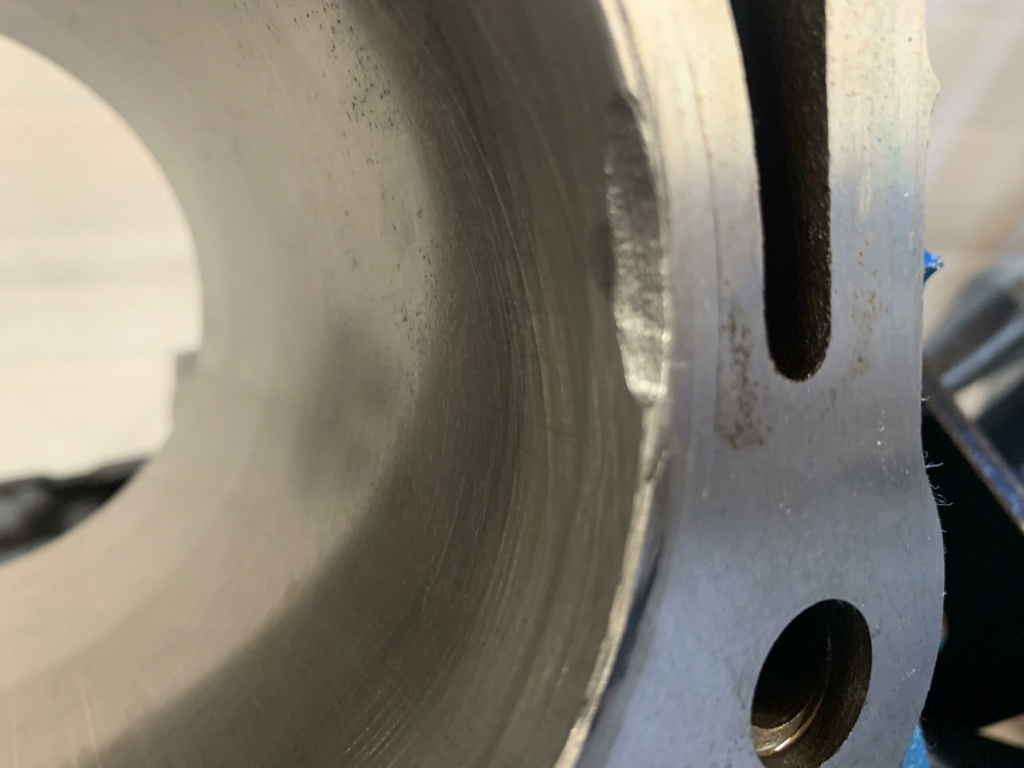

Did you rub that shinny face on the outside ring of that valve when you took it apart, or what?

It sure looks like you have some uneven wear load on those non blue lifter wheels and some look prestine.

When you check your top end oiling make sure they are all even and the pushrod holes are all clear.

I would set that Dominator up for Track only, likely without a power valve for less tuning headache and things to go wrong. The Diaphragm on the Power Valve can leak, and it goes straight into the engine and richens up the fuel mixture and it may be small enough not to even notice.

Get a 750 or 800 Holley DP for the Street. Not a 850 or 950 or 1,000. They are much bigger fuel pigs in by experience. I am not going to go into them here but, it's enough to turn me off in a dual mode of street and track use of the big 4150's. Get a used 4779 or 4780 Holley and play with that. If that 950 worked good on the 501, it is another good reason not to monkey with it.

An always oil your threads so they don't wear out as fast, Holley love to strip screws.

I would also recommend you throw the Wide Band at the track out, or at least until you get a lot of carb tuning experience and a high dollar one that is accurate.

I see guys trying to street tune these Holley's with them, looking to get computer fuel injection numbers at all loads and rpms, just wear the screws out chasing their tail.

Check your manifold at steady cruise speed in high gear, before you make any power valve decisions on sizing.

If Holley started making 1Hg valves, that's Retarded. 2.5Hg was as low as they used to sell, and I would not be suprized if their was not a time when 3.5Hg was.

When you tune your idle screws make sure the engine is at full operating temperature. When you get highest vacuum, move the a little more each way and see if rpm increases or the engine smooths out any. After you do them long enough you get a better feel for doing it that way I guess.

My Hastings ring instructions were about the same as yours, wanted less gap on the top. All old shop manuals all my life just the opposite. I get it on Pro level engines that come apart all the time for refresh.

Did you rub that shinny face on the outside ring of that valve when you took it apart, or what?

It sure looks like you have some uneven wear load on those non blue lifter wheels and some look prestine.

When you check your top end oiling make sure they are all even and the pushrod holes are all clear.

supervel45- Posts : 4498

Join date : 2013-09-04

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

no never touched the valve and they all look like that shiny on the edge for some reason probably from touching the aluminum piston is my guess .

oh you can run those carbs without the power valves? do i have to block off the holes?

oh you can run those carbs without the power valves? do i have to block off the holes?

supervel45 wrote:Your Carter and Quadra Jets Metering Rods Run off vacuum to mostly, QJet has a mechanical lift off the secondary air door though for the rods.

I would set that Dominator up for Track only, likely without a power valve for less tuning headache and things to go wrong. The Diaphragm on the Power Valve can leak, and it goes straight into the engine and richens up the fuel mixture and it may be small enough not to even notice.

Get a 750 or 800 Holley DP for the Street. Not a 850 or 950 or 1,000. They are much bigger fuel pigs in by experience. I am not going to go into them here but, it's enough to turn me off in a dual mode of street and track use of the big 4150's. Get a used 4779 or 4780 Holley and play with that. If that 950 worked good on the 501, it is another good reason not to monkey with it.

An always oil your threads so they don't wear out as fast, Holley love to strip screws.

I would also recommend you throw the Wide Band at the track out, or at least until you get a lot of carb tuning experience and a high dollar one that is accurate.

I see guys trying to street tune these Holley's with them, looking to get computer fuel injection numbers at all loads and rpms, just wear the screws out chasing their tail.

Check your manifold at steady cruise speed in high gear, before you make any power valve decisions on sizing.

If Holley started making 1Hg valves, that's Retarded. 2.5Hg was as low as they used to sell, and I would not be suprized if their was not a time when 3.5Hg was.

When you tune your idle screws make sure the engine is at full operating temperature. When you get highest vacuum, move the a little more each way and see if rpm increases or the engine smooths out any. After you do them long enough you get a better feel for doing it that way I guess.

My Hastings ring instructions were about the same as yours, wanted less gap on the top. All old shop manuals all my life just the opposite. I get it on Pro level engines that come apart all the time for refresh.

Did you rub that shinny face on the outside ring of that valve when you took it apart, or what?

It sure looks like you have some uneven wear load on those non blue lifter wheels and some look prestine.

When you check your top end oiling make sure they are all even and the pushrod holes are all clear.

maverick172- Posts : 205

Join date : 2022-10-16

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Holley Power Valve Block off Plug.

https://www.summitracing.com/parts/hly-26-36?seid=srese1&gclid=CjwKCAjwvJyjBhApEiwAWz2nLXI0SyWkR21MYKYoAyBnP0PQT8sknbEaKP0A_tLD3njjimso2wkiSRoCDtEQAvD_BwE

Well at least the exhaust valve rotated good. I guess! Yikes

Yikes

https://www.summitracing.com/parts/hly-26-36?seid=srese1&gclid=CjwKCAjwvJyjBhApEiwAWz2nLXI0SyWkR21MYKYoAyBnP0PQT8sknbEaKP0A_tLD3njjimso2wkiSRoCDtEQAvD_BwE

Well at least the exhaust valve rotated good. I guess!

Yikes

Yikes

supervel45- Posts : 4498

Join date : 2013-09-04

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Check your spark plugs for aluminum deposits on the porcelain insulator.

supervel45- Posts : 4498

Join date : 2013-09-04

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

one thing i should note the 4 "burned rockers " were all on the drivers side of the block if that makes sense not sure .[/quote]

Drivers side gets oil last. So, there is pressure/volume drop on that side.[/quote]

well that makes sense why they burned up . what generally cause pressure drop at the end the oil feed ? would going to a higher weight oil maybe help ? maybe i will try 15w40. i could put a high volume high pressure pump in while i have engine apart too i have a high volume in there now but ... i do have a hv/hp pump sitting here that would drop right in

maverick172- Posts : 205

Join date : 2022-10-16

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

maverick172 wrote:

one thing i should note the 4 "burned rockers " were all on the drivers side of the block if that makes sense not sure .

Drivers side gets oil last. So, there is pressure/volume drop on that side.[/quote]

well that makes sense why they burned up . what generally cause pressure drop at the end the oil feed ? would going to a higher weight oil maybe help ? maybe i will try 15w40. i could put a high volume high pressure pump in while i have engine apart too i have a high volume in there now but ... i do have a hv/hp pump sitting here that would drop right in [/quote]

Fix lifters to move oil easier

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

what do you mean by fix lifters to move oil easier?

well that makes sense why they burned up . what generally cause pressure drop at the end the oil feed ? would going to a higher weight oil maybe help ? maybe i will try 15w40. i could put a high volume high pressure pump in while i have engine apart too i have a high volume in there now but ... i do have a hv/hp pump sitting here that would drop right in [/quote]

Fix lifters to move oil easier[/quote]

Lem Evans wrote:maverick172 wrote:

one thing i should note the 4 "burned rockers " were all on the drivers side of the block if that makes sense not sure .

Drivers side gets oil last. So, there is pressure/volume drop on that side.

well that makes sense why they burned up . what generally cause pressure drop at the end the oil feed ? would going to a higher weight oil maybe help ? maybe i will try 15w40. i could put a high volume high pressure pump in while i have engine apart too i have a high volume in there now but ... i do have a hv/hp pump sitting here that would drop right in [/quote]

Fix lifters to move oil easier[/quote]

maverick172- Posts : 205

Join date : 2022-10-16

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Lem Evans wrote:maverick172 wrote:

one thing i should note the 4 "burned rockers " were all on the drivers side of the block if that makes sense not sure .

Drivers side gets oil last. So, there is pressure/volume drop on that side.

well that makes sense why they burned up . what generally cause pressure drop at the end the oil feed ? would going to a higher weight oil maybe help ? maybe i will try 15w40. i could put a high volume high pressure pump in while i have engine apart too i have a high volume in there now but ... i do have a hv/hp pump sitting here that would drop right in [/quote]

Fix lifters to move oil easier[/quote]

All you need is a scratch thru the hole and into the center pocket. Use a dremel and barely dust it.

Oil on the drivers side comes from the crossover in the valley where the two 1/8th pipe plugs are. make sure that the plugs are not deep in the holes and obstructing the crossover passage.

Dave De- Posts : 795

Join date : 2011-05-27

Location : Highland, MI

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

hey so i have a update i eyebrowed the bore top i went down .200from top of deck and i went to a 4.50 gasket outeredge and with the new valves in heads i have . 026 of a inch clearance @ the .200 down the hole point i called roger @ kaase and asked him if he thought that was enough clearance he was not sure he asked me to call kasse on monday and ask .

my ring top of travel is .270 down the hole and i do not want to get any lower than i am now i could go another .025 might give me another . 002 or so clearance on my valve to cylinder bore clearance i do not know.

i said i only see 2 options . either i grind the valves smaller diameter ? or put a thicker head gasket both of which are not ideal . i wonder if offset dowels would be the answer?

how much clearance have you guys seen and run in this situation . if i new that a 4.39 bore was going to be a pain i would of went 4.44 right away and would not of had these issues

ps i see ghosting on these cylinder bores as deep or even 2 cylinder lower than the ring travel . so i cannot clearnace down that deep abviously .

. one more thing do you think the valves bent and causeing the valves to rotate and dust the edges of the bores deeper as part of the bent valves .

i do not want to put this engine together till i am 100% confident these is no more clearance issues

thanks again guys

my ring top of travel is .270 down the hole and i do not want to get any lower than i am now i could go another .025 might give me another . 002 or so clearance on my valve to cylinder bore clearance i do not know.

i said i only see 2 options . either i grind the valves smaller diameter ? or put a thicker head gasket both of which are not ideal . i wonder if offset dowels would be the answer?

how much clearance have you guys seen and run in this situation . if i new that a 4.39 bore was going to be a pain i would of went 4.44 right away and would not of had these issues

ps i see ghosting on these cylinder bores as deep or even 2 cylinder lower than the ring travel . so i cannot clearnace down that deep abviously .

. one more thing do you think the valves bent and causeing the valves to rotate and dust the edges of the bores deeper as part of the bent valves .

i do not want to put this engine together till i am 100% confident these is no more clearance issues

thanks again guys

maverick172- Posts : 205

Join date : 2022-10-16

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Dave De wrote:Lem Evans wrote:maverick172 wrote:

one thing i should note the 4 "burned rockers " were all on the drivers side of the block if that makes sense not sure .

Drivers side gets oil last. So, there is pressure/volume drop on that side.

well that makes sense why they burned up . what generally cause pressure drop at the end the oil feed ? would going to a higher weight oil maybe help ? maybe i will try 15w40. i could put a high volume high pressure pump in while i have engine apart too i have a high volume in there now but ... i do have a hv/hp pump sitting here that would drop right in

Fix lifters to move oil easier[/quote]

All you need is a scratch thru the hole and into the center pocket. Use a dremel and barely dust it.

Oil on the drivers side comes from the crossover in the valley where the two 1/8th pipe plugs are. make sure that the plugs are not deep in the holes and obstructing the crossover passage.[/quote]

i pointed at ahe point just a little channel there thats it . how deep and how wide?

maverick172- Posts : 205

Join date : 2022-10-16

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

So, long story short.....1.70" exh. valve does not work in a 4.390" bore?

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

it appears that way . wish i would of known . i would of done a 4.44 bore . now i got to deal with it . how much bore to valve clearance you think is good ? i guess at a minimum ?Lem Evans wrote:So, long story short.....1.70" exh. valve does not work in a 4.390" bore?

maverick172- Posts : 205

Join date : 2022-10-16

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

maverick172 wrote:it appears that way . wish i would of known . i would of done a 4.44 bore . now i got to deal with it . how much bore to valve clearance you think is good ? i guess at a minimum ?Lem Evans wrote:So, long story short.....1.70" exh. valve does not work in a 4.390" bore?

It''ll change when the valve guides get worn is all i know.

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

It seem like the exhaust valves rotated by the silver ring on the face. The spot a 2:45 o'clock that is big is likely it's last hard contact when the engine quit.

Going by the marks on the pistons exhaust side, it only hit on the outside, so it could not make a ring like that without turning, that I can see.

If the silver is aluminum I think the valve could have been kissing the piston for a while because the camshaft was running retarded and it may have been a gradual thing that progressed with time.

It's hard to say, if the above is correct, if the bore contact or piston contact promoted the rotation.

I would not cut the heads on a 4.39 block and a 4.42" looks much better now!

If you get a chance, if you could take another picture from the bottom of the block, more to the center of the cylinder, it would be nice. Then we can see how much, if the valve is covered, it is out side the cylinder wall.

Lem has a point and is right on the guide wear. You would theoretically would have to have .052" guide slop to get there though at .026" clearance.

You should ask Kaase on the clearance as well as custom offset dowel pins when you talk to him. He may have some, or can make some, if it is feasible.

If it was me I might ask Kaase if he could drop a 1.76" valve in the mail, to use as a gauging tool.

I would run it through all eight cylinders to check my cut for location.

It would also be the exact .030" clearance oversize I was hunting for on the block. Later I could modify the valve diameter or make a cutting tool out of it if need be, or both.

Going by the marks on the pistons exhaust side, it only hit on the outside, so it could not make a ring like that without turning, that I can see.

If the silver is aluminum I think the valve could have been kissing the piston for a while because the camshaft was running retarded and it may have been a gradual thing that progressed with time.

It's hard to say, if the above is correct, if the bore contact or piston contact promoted the rotation.

I would not cut the heads on a 4.39 block and a 4.42" looks much better now!

If you get a chance, if you could take another picture from the bottom of the block, more to the center of the cylinder, it would be nice. Then we can see how much, if the valve is covered, it is out side the cylinder wall.

Lem has a point and is right on the guide wear. You would theoretically would have to have .052" guide slop to get there though at .026" clearance.

You should ask Kaase on the clearance as well as custom offset dowel pins when you talk to him. He may have some, or can make some, if it is feasible.

If it was me I might ask Kaase if he could drop a 1.76" valve in the mail, to use as a gauging tool.

I would run it through all eight cylinders to check my cut for location.

It would also be the exact .030" clearance oversize I was hunting for on the block. Later I could modify the valve diameter or make a cutting tool out of it if need be, or both.

supervel45- Posts : 4498

Join date : 2013-09-04

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Dave De wrote:Lem Evans wrote:maverick172 wrote:

one thing i should note the 4 "burned rockers " were all on the drivers side of the block if that makes sense not sure .

Drivers side gets oil last. So, there is pressure/volume drop on that side.

well that makes sense why they burned up . what generally cause pressure drop at the end the oil feed ? would going to a higher weight oil maybe help ? maybe i will try 15w40. i could put a high volume high pressure pump in while i have engine apart too i have a high volume in there now but ... i do have a hv/hp pump sitting here that would drop right in

Fix lifters to move oil easier[/quote]

All you need is a scratch thru the hole and into the center pocket. Use a dremel and barely dust it.

Oil on the drivers side comes from the crossover in the valley where the two 1/8th pipe plugs are. make sure that the plugs are not deep in the holes and obstructing the crossover passage.[/quote]

That was a good catch Dave. I almost forget about setting the plug depth, thing.

Those plugs are the ones with the rounded face in the front, that's what blocks the channel, I believe.

What do you think of the OP's 15 to 25 pound idle oil pressure on the street with this setup like that?

The more we get into this I am with you on chunking those exhaust lifters. The valve silver ring about sealed the deal for me, if it where mine.

supervel45- Posts : 4498

Join date : 2013-09-04

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

so you believe .030 is enough clearance total for side of valve to bore clearance . ?

i am with you when you say the "silver ring on valve it makes me more confident the valve turned while being slightly retarded and was nicking the pistons as they rotated .so if thats the case that would make the valves nick the cylinder wall all the more as they rotated inside the engine .

i might go another .025 deeper in my cut and see if i can get another .003 or .004 clearance on my valve .

i am with you when you say the "silver ring on valve it makes me more confident the valve turned while being slightly retarded and was nicking the pistons as they rotated .so if thats the case that would make the valves nick the cylinder wall all the more as they rotated inside the engine .

i might go another .025 deeper in my cut and see if i can get another .003 or .004 clearance on my valve .

supervel45 wrote:It seem like the exhaust valves rotated by the silver ring on the face. The spot a 2:45 o'clock that is big is likely it's last hard contact when the engine quit.

Going by the marks on the pistons exhaust side, it only hit on the outside, so it could not make a ring like that without turning, that I can see.

If the silver is aluminum I think the valve could have been kissing the piston for a while because the camshaft was running retarded and it may have been a gradual thing that progressed with time.

It's hard to say, if the above is correct, if the bore contact or piston contact promoted the rotation.

I would not cut the heads on a 4.39 block and a 4.42" looks much better now!

If you get a chance, if you could take another picture from the bottom of the block, more to the center of the cylinder, it would be nice. Then we can see how much, if the valve is covered, it is out side the cylinder wall.

Lem has a point and is right on the guide wear. You would theoretically would have to have .052" guide slop to get there though at .026" clearance.

You should ask Kaase on the clearance as well as custom offset dowel pins when you talk to him. He may have some, or can make some, if it is feasible.

If it was me I might ask Kaase if he could drop a 1.76" valve in the mail, to use as a gauging tool.

I would run it through all eight cylinders to check my cut for location.

It would also be the exact .030" clearance oversize I was hunting for on the block. Later I could modify the valve diameter or make a cutting tool out of it if need be, or both.

maverick172- Posts : 205

Join date : 2022-10-16

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

maverick172 wrote:it appears that way . wish i would of known . i would of done a 4.44 bore . now i got to deal with it . how much bore to valve clearance you think is good ? i guess at a minimum ?Lem Evans wrote:So, long story short.....1.70" exh. valve does not work in a 4.390" bore?

Were you told it'd work with the + .030" bore or did you assume it would?

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

both ..Lem Evans wrote:maverick172 wrote:it appears that way . wish i would of known . i would of done a 4.44 bore . now i got to deal with it . how much bore to valve clearance you think is good ? i guess at a minimum ?Lem Evans wrote:So, long story short.....1.70" exh. valve does not work in a 4.390" bore?

Were you told it'd work with the + .030" bore or did you assume it would?

maverick172- Posts : 205

Join date : 2022-10-16

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

The articles were pushing 1.72" valves on the small bores when they came out, if I recall correctly.

supervel45- Posts : 4498

Join date : 2013-09-04

Re: 521 cid broken camshaft dowel for timing gear . bent valves

Re: 521 cid broken camshaft dowel for timing gear . bent valves

no way they would of worked.supervel45 wrote:The articles were pushing 1.72" valves on the small bores when they came out, if I recall correctly.

what your thoughts on timing chain it the roller bearing on the back vs the brass bushing ?

maverick172- Posts : 205

Join date : 2022-10-16

Page 4 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Similar topics

Similar topics» Broken dowel pin in timing gear

» Advance Cam or Not ?

» Found some bent valves...

» I bent 6 valves and cant find new ones ???

» Broken timing chain

» Advance Cam or Not ?

» Found some bent valves...

» I bent 6 valves and cant find new ones ???

» Broken timing chain

Page 4 of 5

Permissions in this forum:

You cannot reply to topics in this forum|

|

|