The F250 to F100 turbo project - it's alive.

+17

5pointslow

BBFTorino

460bronco

res0rli9

tfsbbf466

56f100guy

Doug Rahn

Tomasw

jasonf

Mark Miller

FalconEh

dirt_worker

HorsinAround

D. Sea

Mike R

68formalGT

BigBlockRanger

21 posters

Page 4 of 5

Page 4 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

I added a bracket that goes from the rear bracket and spans 2 exhaust studs. This really solidified the mount. I could probably stand on it now.

I also formed the pipe to fit in the rectangle turbo flange to transition to round pipe. I started welding it to the flange yesterday, but not surprisingly ran out of gas.

Fuel lines are also mocked up. Looks like I will need about 3 more feet of hose to complete the fuel system. It's a long way from the back to the front, and back again!

I also formed the pipe to fit in the rectangle turbo flange to transition to round pipe. I started welding it to the flange yesterday, but not surprisingly ran out of gas.

Fuel lines are also mocked up. Looks like I will need about 3 more feet of hose to complete the fuel system. It's a long way from the back to the front, and back again!

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

Worked on the turbo flange. Basically took a piece of 4" exhaust tubing, split it and the formed it into the flange with a ballpeen hammer and a 1/2" socket extension. Then I welded it in place.

Next, I formed the other end to an oval and inserted the other tubing and welded it. Took some hammering and squishing, but it turned out pretty nice for my first time. Certainly good enough for who it is for. Haha.

Made some more braided hoses. I just have one more to make and the fuel system will be plumbed.

Next, I formed the other end to an oval and inserted the other tubing and welded it. Took some hammering and squishing, but it turned out pretty nice for my first time. Certainly good enough for who it is for. Haha.

Made some more braided hoses. I just have one more to make and the fuel system will be plumbed.

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

Hot side is 99% finished. I really tried hard to route the pipe where I could remove the starter and converter nuts without having to drop the crossover pipe. Overall, I am pretty pleased with the fitment. I did learn an important lesson. Start building in the most difficult to access area first, then move from there toward the easy areas. I left the difficult for the last and it really made it take longer that it should have.

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

Friday evening I built the down pipe. It seems straight forward, but was a little tricky. The sheer size of the pipe made it difficult to cut with my chop saw and it is hard to just grab it and hold it with one hand. It needed one small dent to clear the cab mount a little better, but that's no big deal.

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

Went to the shop at about 8pm Saturday night and did some work. After trimming the passenger inner fender, I set the front end back in place. Not a super easy job to do by yourself, but I got it done. Once it had a few bolts into secure it, I set about the task of figuring out how to wedge the intercooler in this thing. For a full size truck, up-front room is at a minimum on these things. The intercooler I bought is probably the biggest anyone could fit without going to a custom made piece. Custom was not an option for me on this semi-low buck build. I had to notch the core support on either end for clearance and modify the hood latch bracket to become the main support for the IC. With the IC just sitting in it's place, it looks like the grill inserts will need little to no modification. I was really hoping that would be the case. Plumbing it may get interesting, but I will cross that bridge when I get to it.

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

Sweet build looking forward to seeing it run

Mike R- Posts : 1381

Join date : 2009-08-05

Age : 63

Location : St Paul Mn

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

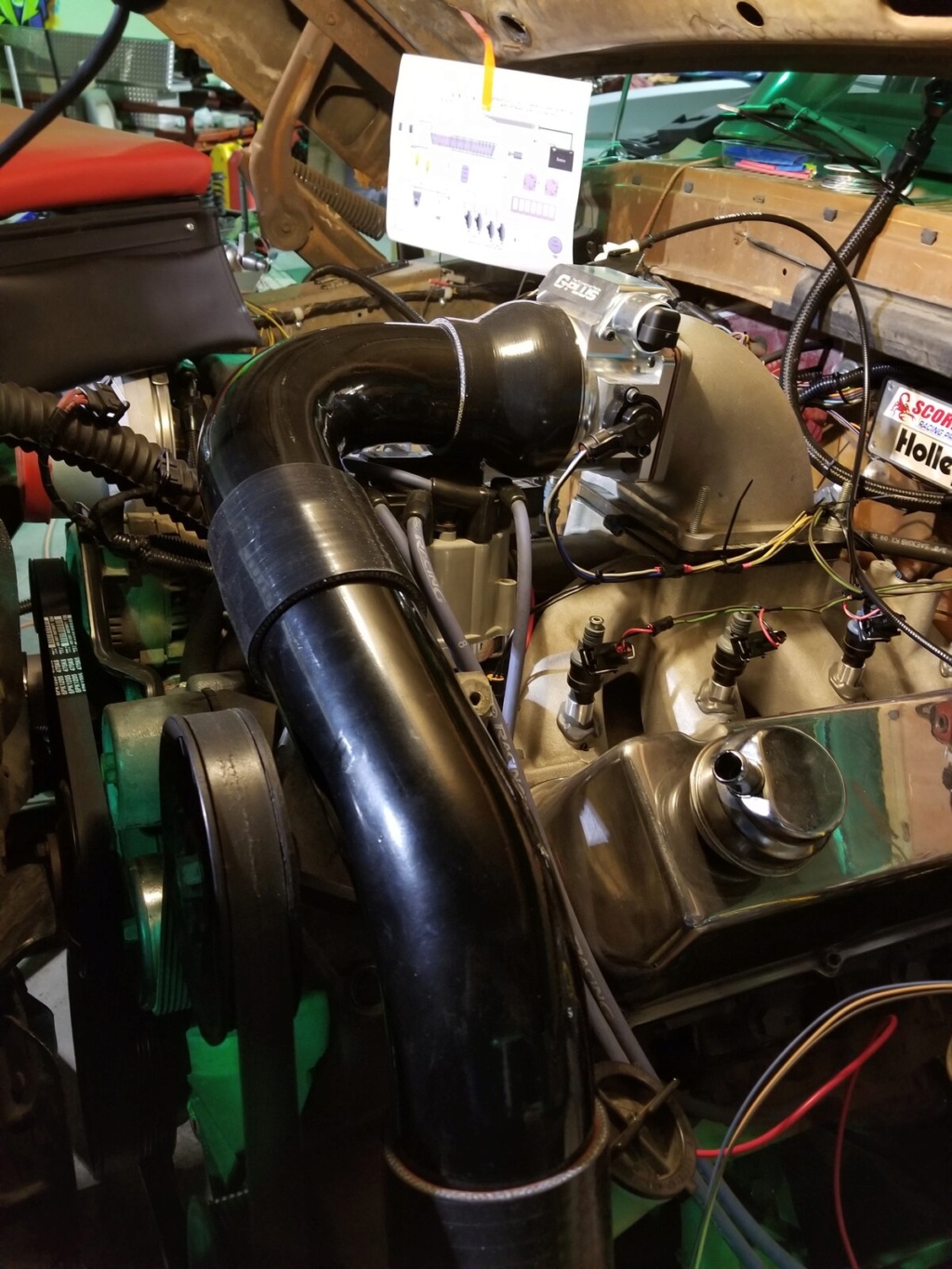

Still plugging away at it. Radiator, hoses, fan, etc are all in now.

Picked up a neat discharge elbow that is for a Dodge that looks like it will work great. It fits the turbo perfectly and aims discharge right at the intercooler inlet. i would like to say I planned it that way, but it was just luck. The rest of the intercooler piping should be here today.

Picked up a neat discharge elbow that is for a Dodge that looks like it will work great. It fits the turbo perfectly and aims discharge right at the intercooler inlet. i would like to say I planned it that way, but it was just luck. The rest of the intercooler piping should be here today.

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

Great project , has come up nice , love it

Gregaust- Posts : 625

Join date : 2009-08-09

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

I made decent progress Thursday night, but it was not without a little trouble. I started filling it with water and noticed it was leaking. Seems the thermostat slipped out of place when I was installing it. Nice.

Converter nuts are on, oil and break-in lube is in, spark plugs are tight, temporary HEI wiring in in, tach is connected, *most* of the water is in it, correct spring is in the fuel pressure regulator. I still need to rob the battery from the Mustang, install thermostat & housing, pre-lube with the drill, stab distributor, put plug wires on, put some fuel in it, turn on electric pump and check for fuel leaks, flip the switch and hope it doesn't catch fire.

Converter nuts are on, oil and break-in lube is in, spark plugs are tight, temporary HEI wiring in in, tach is connected, *most* of the water is in it, correct spring is in the fuel pressure regulator. I still need to rob the battery from the Mustang, install thermostat & housing, pre-lube with the drill, stab distributor, put plug wires on, put some fuel in it, turn on electric pump and check for fuel leaks, flip the switch and hope it doesn't catch fire.

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

Friday night I robbed the battery from the Mustang, pre-lubed the motor, stabbed the distributor (which took FOREVER) put the plug wires on it, dumped some gas in it and checked for fuel leaks. It had 2. One at the regulator because a fitting was completely loose and the other at the carb. That Dominator has the ability to feed the fuel bowl from either side, so the other side has a plug. I left the plug out for some reason. Flipped the switch for the fuel pump and fuel shot out of the carb bowl all over the intake!! Yikes! Once all that was corrected, I turned it on, hit the starter button and it roared to life. Almost too easy. At one point it started running rough and I thought “oh no I killed the cam”. Turns out I didn’t have the #2 and #4 plug wires on good and they had fallen off the plugs. Lol. Cam seems to have broken-in just fine. Turbo spins and it makes turbo noises and the 5” open down pipe is fairly thunderous. Next thing to do is to start wiring up the Megasquirt!

I also put some trim back on (had to shorten it from long bed to short bed) and made a shield to keep potential rear mail seal leakage or trans seal leakage from getting on the crossover pipe.

I also put some trim back on (had to shorten it from long bed to short bed) and made a shield to keep potential rear mail seal leakage or trans seal leakage from getting on the crossover pipe.

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

Nice sounds good!!

Mark Miller- Posts : 1958

Join date : 2009-09-01

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

Thanks! I am super happy that I did not have any cam break-in issues.

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

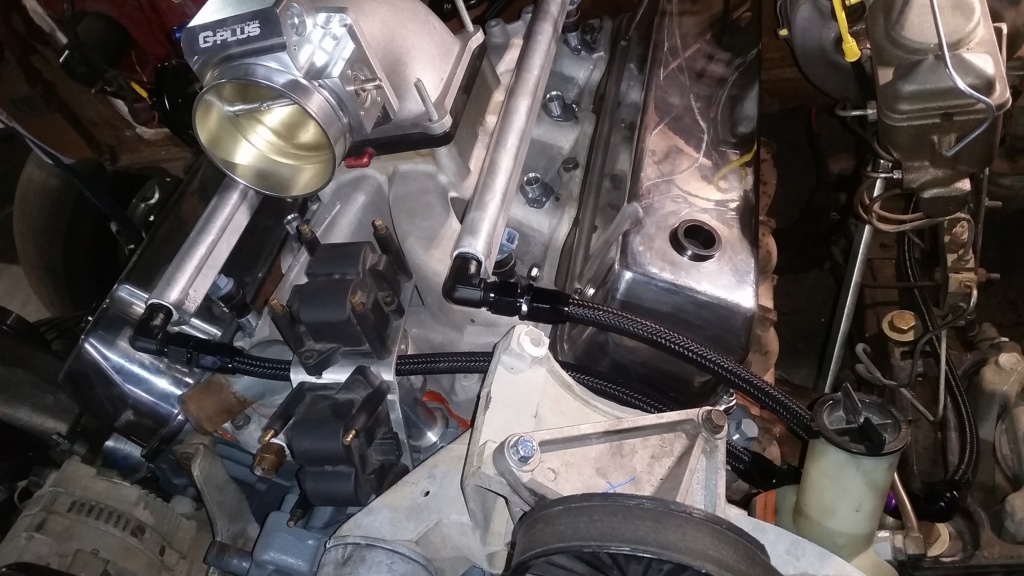

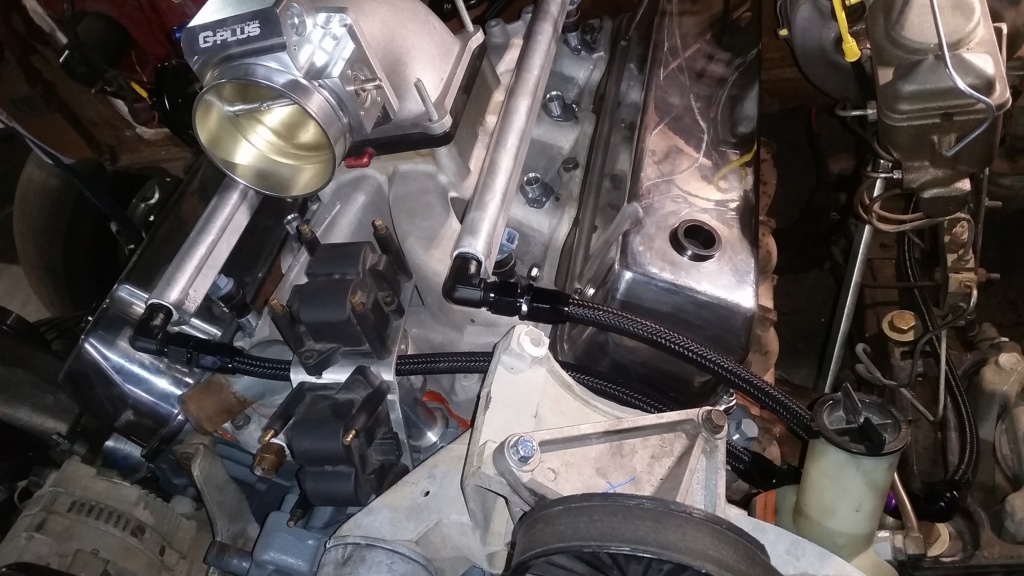

With the exception of the wideband input, the MS is completely wired up.

I loaded TunerStudio onto an old Presario 700 running winXP. Because of the age of the laptop, I was concerned that I might have connectivity issues with the USB to serial adapter. But, it worked perfectly. It connected to the MS and loaded a new base tune in without any fuss.

This MS is the one I built years ago for the original big block Ranger project. I ran it for a short time in that truck and later sold it to a friend when that truck was finally going away. He kept it, but never used it and I ended up getting it back from him when I was looking to use a MS to control the ignition in the Mustang. It worked GREAT for that. This will be the first time I have tried to control fuel AND ignition so it should be fun.

Next up is rerouting fuel lines, installing the rails, checking for leaks and installing the ignition coils in place of the distributor.

FYI: that password was left from a previous user. lol

I loaded TunerStudio onto an old Presario 700 running winXP. Because of the age of the laptop, I was concerned that I might have connectivity issues with the USB to serial adapter. But, it worked perfectly. It connected to the MS and loaded a new base tune in without any fuss.

This MS is the one I built years ago for the original big block Ranger project. I ran it for a short time in that truck and later sold it to a friend when that truck was finally going away. He kept it, but never used it and I ended up getting it back from him when I was looking to use a MS to control the ignition in the Mustang. It worked GREAT for that. This will be the first time I have tried to control fuel AND ignition so it should be fun.

Next up is rerouting fuel lines, installing the rails, checking for leaks and installing the ignition coils in place of the distributor.

FYI: that password was left from a previous user. lol

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

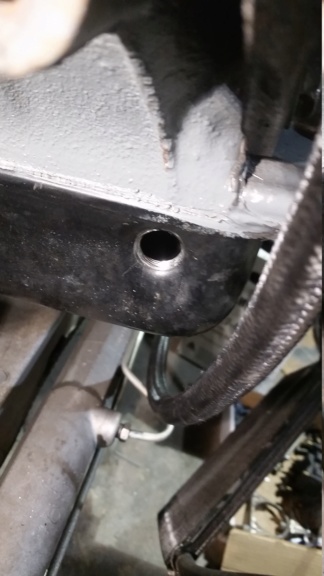

Rail mounts made and fuel system is plumbed.

And it leaks.

Well the driver's rail does not, but the passenger rail does. Checked holes (I drilled) and they were on the big side. I don't know what the problem is but iI got some o-rings for using an LS1 injector in an LS2 intake. It is a special o-ring that uses a fatter 15.25mm o-ring with the same ID. They seem to fit the rail really nice.

I might have enough time this afternoon to button it back up and test for leaks.

And it leaks.

Well the driver's rail does not, but the passenger rail does. Checked holes (I drilled) and they were on the big side. I don't know what the problem is but iI got some o-rings for using an LS1 injector in an LS2 intake. It is a special o-ring that uses a fatter 15.25mm o-ring with the same ID. They seem to fit the rail really nice.

I might have enough time this afternoon to button it back up and test for leaks.

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

It still leaked. It was fine at 20 psi, but once I turned it up to 40+ it leaked.

I decided to play with the old rail, drill a bunch of test holes to get this situation figured out. First, I painstakingly set up the drill press so that it was drilling straight and square. I chucked up the 17/32 bit just to see if maybe last time I had something crooked. I drilled it, then pulled the bit and the hole was way bigger than the bit. Interesting. I chucked up a 1/2" bit that I really though wasn't in very good condition and drilled a 1/2" hole in the rail. Removed bit and slid it in. Spot on. Bit fit the hole perfectly. So I decided it must be the bit. The 1/2" makes long aluminum curls and the 17/32" makes chips . I suppose the chips do not clear well and causes the hole to end up larger. I chucked up the 17/32" in my 1/2" hand drill and just made a quick finish pass in the 1/2" hole. Checked it afterwards, perfect size. Whoo hoo I have a technique. I practiced a few more times on the old rail perfecting my technique and getting my depth set correctly for the shoulder down in the hole. Then it was go time on the new rail. Drilled the 1/2" holes, smaller feed holes and then hit them with a 17/32" clean up pass and it ended up perfect. Wheeeeeeeewwwwww.

Finished up the new rail the other night. No leaks this time.

I decided to play with the old rail, drill a bunch of test holes to get this situation figured out. First, I painstakingly set up the drill press so that it was drilling straight and square. I chucked up the 17/32 bit just to see if maybe last time I had something crooked. I drilled it, then pulled the bit and the hole was way bigger than the bit. Interesting. I chucked up a 1/2" bit that I really though wasn't in very good condition and drilled a 1/2" hole in the rail. Removed bit and slid it in. Spot on. Bit fit the hole perfectly. So I decided it must be the bit. The 1/2" makes long aluminum curls and the 17/32" makes chips . I suppose the chips do not clear well and causes the hole to end up larger. I chucked up the 17/32" in my 1/2" hand drill and just made a quick finish pass in the 1/2" hole. Checked it afterwards, perfect size. Whoo hoo I have a technique. I practiced a few more times on the old rail perfecting my technique and getting my depth set correctly for the shoulder down in the hole. Then it was go time on the new rail. Drilled the 1/2" holes, smaller feed holes and then hit them with a 17/32" clean up pass and it ended up perfect. Wheeeeeeeewwwwww.

Finished up the new rail the other night. No leaks this time.

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

Fancy

nice work, I've been following your build and I'm impressed. Keep the updates comming

nice work, I've been following your build and I'm impressed. Keep the updates comming

Mike R- Posts : 1381

Join date : 2009-08-05

Age : 63

Location : St Paul Mn

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

Backfired the intake tube off trying to start it the first time on the Megasquirt. Turns out I had the coils flop flopped.

Once I corrected that,nit fired right off. It is too lean right now and won't stay running unless you wing the throttle.

I am very happy that it runs on the MS now! That was a big hurdle to clear!!

https://youtu.be/CNZX8E9h8yg

Once I corrected that,nit fired right off. It is too lean right now and won't stay running unless you wing the throttle.

I am very happy that it runs on the MS now! That was a big hurdle to clear!!

https://youtu.be/CNZX8E9h8yg

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

Build has come a long way since I was last on here. Turbo set up turned out well. Should be super fun with the stroker and turbo

tfsbbf466- Posts : 180

Join date : 2012-03-08

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

Thanks! It has kinda been on the back burner for a little while. We took a detour and did a quick GT45 blow thru setup on our 302/T5 Mustang. I wanted to get it up and running because it will be our ride for Rocky Mountain Race Week this year. It previously had a nitrous system on it and the hope it is will run about the same without having to fill the bottle all week. We built and installed another Megasquirt (spark only) in it so we can have programmable timing, rev limits, 2 step and the ability to datalog.

I just have a few things to do on the Mustang and then I will be back on this project.

I just have a few things to do on the Mustang and then I will be back on this project.

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

Re: The F250 to F100 turbo project - it's alive.

Re: The F250 to F100 turbo project - it's alive.

Got the truck running and idling on the Megasquirt. One big step closer to moving under it's own power.

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

Page 4 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Similar topics

Similar topics» 2001 F250 7.3L Turbo Diesel won't start

» Project turbo True Street

» Turbo 547 BBF Project Part Out -- IDT Block, A460 heads, etc

» twin turbo 521 turbo specs

» C intake or turbo hat turbo headers

» Project turbo True Street

» Turbo 547 BBF Project Part Out -- IDT Block, A460 heads, etc

» twin turbo 521 turbo specs

» C intake or turbo hat turbo headers

Page 4 of 5

Permissions in this forum:

You cannot reply to topics in this forum