06 Mustang build

+2

maverick172

supervel45

6 posters

Page 1 of 4

Page 1 of 4 • 1, 2, 3, 4

06 Mustang build

06 Mustang build

I’m going to start this thread and I’ll make a few reply posts so I can come back and edit them to get caught up.

This started when I sold my pulling truck roller and the short block and I was left with several parts including a 429 and 460 stock engines. My fully ported A429

heads victor intake a few cams and other odds and ends.

Facebook marketplace revealed a 2006 V6 mustang with 192k on it. I bought it and tuned it up and drove it while gathering parts. The hood had some damage but I figured that I would end up with a cowl anyway.

This started when I sold my pulling truck roller and the short block and I was left with several parts including a 429 and 460 stock engines. My fully ported A429

heads victor intake a few cams and other odds and ends.

Facebook marketplace revealed a 2006 V6 mustang with 192k on it. I bought it and tuned it up and drove it while gathering parts. The hood had some damage but I figured that I would end up with a cowl anyway.

curiousgeorge- Posts : 191

Join date : 2008-12-03

Age : 41

BigBlockRanger, dfree383 and Mark Miller like this post

Re: 06 Mustang build

Re: 06 Mustang build

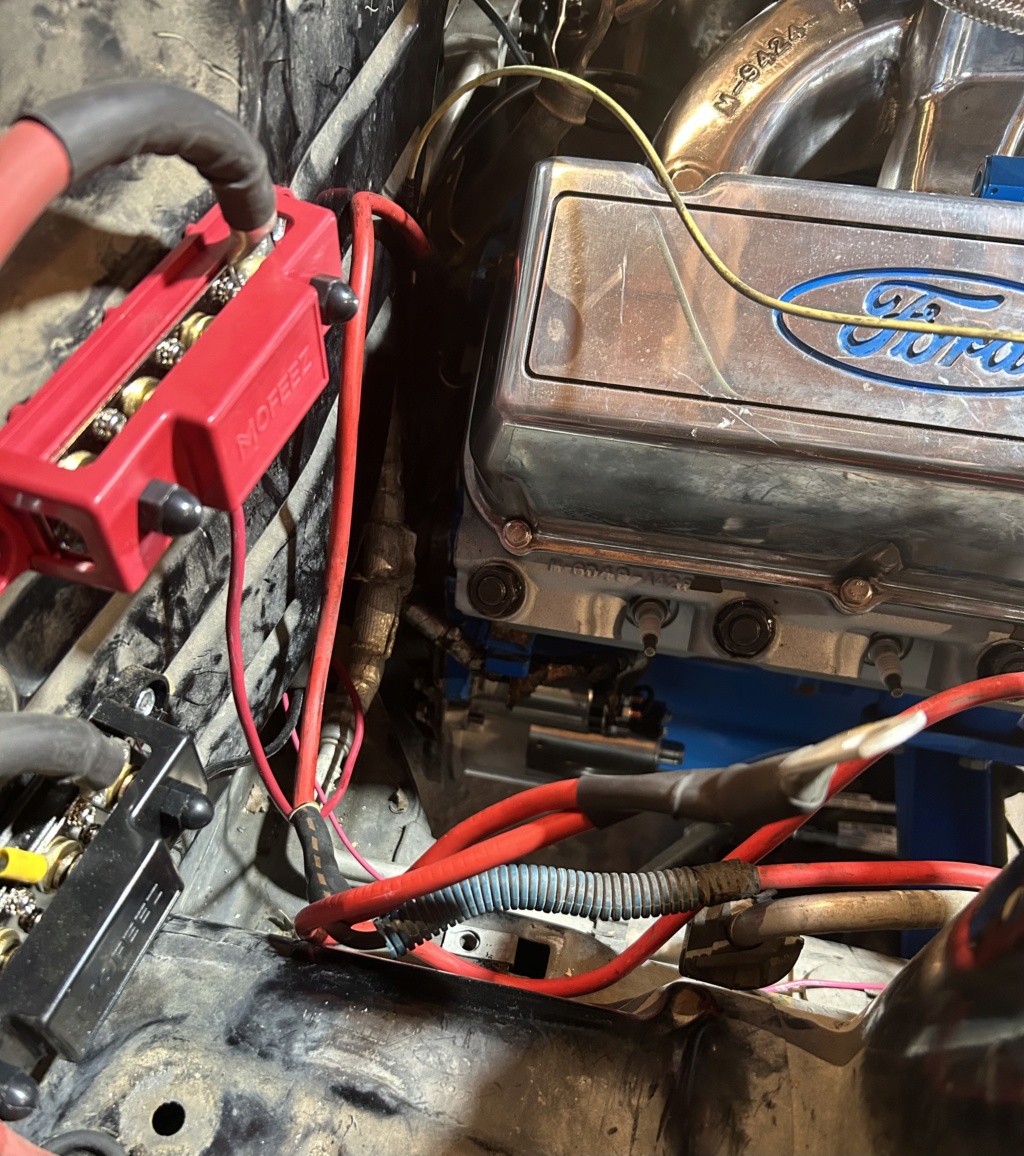

The engine

I originally planned on using the 429 then I found the block had cracked from not draining the block the last time it was ran. So I pulled the 460 I had in the corner apart only to find the block needed bored. I ended up grinding and drilling the crack and welding it then capped it with a coat of JB weld incase there were any leaks. I installed the 460 rotating assembly into the C9 block with fresh rings and bearings. Std bore -22cc dish pistons.

After about 9 months at the machine shop for a broken intake seat I finally had my heads back with M-6513-A351 springs that I removed when I bought the heads new and was ready to finish putting the engine together.

Cam is a Comp XM288H 244/254 @50 .580/.585 lift112LSA

Motorsports Victor port matched to the heads. Currently have an 830 Holley and a plate to be hooked up later.

I originally planned on using the 429 then I found the block had cracked from not draining the block the last time it was ran. So I pulled the 460 I had in the corner apart only to find the block needed bored. I ended up grinding and drilling the crack and welding it then capped it with a coat of JB weld incase there were any leaks. I installed the 460 rotating assembly into the C9 block with fresh rings and bearings. Std bore -22cc dish pistons.

After about 9 months at the machine shop for a broken intake seat I finally had my heads back with M-6513-A351 springs that I removed when I bought the heads new and was ready to finish putting the engine together.

Cam is a Comp XM288H 244/254 @50 .580/.585 lift112LSA

Motorsports Victor port matched to the heads. Currently have an 830 Holley and a plate to be hooked up later.

Last edited by curiousgeorge on February 12th 2024, 11:03 pm; edited 1 time in total

curiousgeorge- Posts : 191

Join date : 2008-12-03

Age : 41

BigBlockRanger and Mark Miller like this post

Re: 06 Mustang build

Re: 06 Mustang build

I knew the 7.5 rearend wasn’t going to cut it with the BB so I found an 8.8 with 3.31 that had a whine to it. I brought it home and took it apart every thing looked good but it was a open diff. I had one laying around out of a pickup so I took it apart ordered a bearing install kit and put the 3.55 trac loc in it. I put around 5k miles on it before I started the swap.

I pulled the car into the garage the first of November and started tearing it apart. Pulled the v6 and trans out and started getting everything ready for the 460. I had a c6 that had been laying around in the garage for 10 years so I pulled it apart and everything in it looked brand new so I ordered a gasket set and a shift kit to put it back together. When I put the shift kit in the valve body every spring I changed was the same color so I’m assuming that one had already been installed.

The original plan was to make it look as stock as possible. To make the factory tach work I needed a reluctor wheel on the crank so I ordered one and had the center machined out to slide onto the hatchet weight. Once I had it all together it fit great but I couldn’t find a place to mount the crank sensor. The only place it would fit was behind the fuel pump but couldn’t put it there since I’m running a mechanical Holley pump. But on a positive note I found a 5 gauge set on marketplace for $300 that included 5” tach and speedo that were new and they fit into the gauge bezel like they were made for it. I hadn’t put the led’s in for the turn signal, high beam and I put a yellow and red in there just haven’t decided what they are going to be used for yet.

I pulled the car into the garage the first of November and started tearing it apart. Pulled the v6 and trans out and started getting everything ready for the 460. I had a c6 that had been laying around in the garage for 10 years so I pulled it apart and everything in it looked brand new so I ordered a gasket set and a shift kit to put it back together. When I put the shift kit in the valve body every spring I changed was the same color so I’m assuming that one had already been installed.

The original plan was to make it look as stock as possible. To make the factory tach work I needed a reluctor wheel on the crank so I ordered one and had the center machined out to slide onto the hatchet weight. Once I had it all together it fit great but I couldn’t find a place to mount the crank sensor. The only place it would fit was behind the fuel pump but couldn’t put it there since I’m running a mechanical Holley pump. But on a positive note I found a 5 gauge set on marketplace for $300 that included 5” tach and speedo that were new and they fit into the gauge bezel like they were made for it. I hadn’t put the led’s in for the turn signal, high beam and I put a yellow and red in there just haven’t decided what they are going to be used for yet.

Last edited by curiousgeorge on February 13th 2024, 9:43 pm; edited 1 time in total

curiousgeorge- Posts : 191

Join date : 2008-12-03

Age : 41

BigBlockRanger, jasonf and Mark Miller like this post

Re: 06 Mustang build

Re: 06 Mustang build

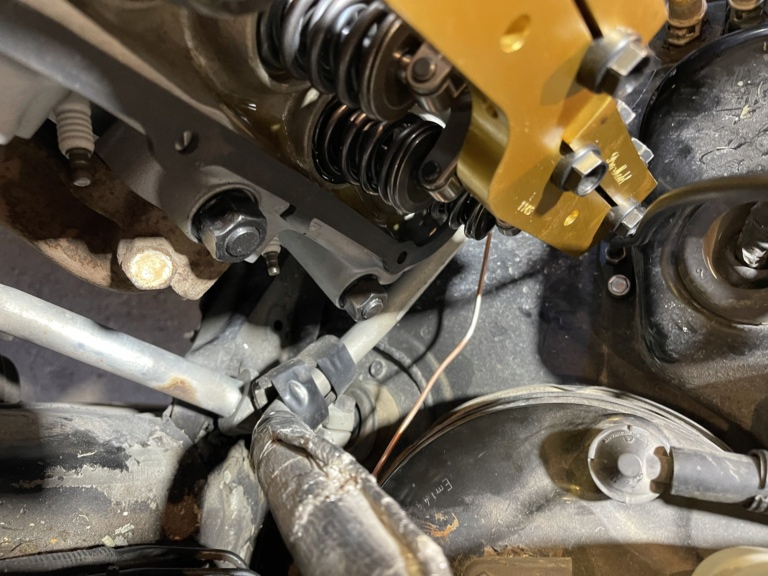

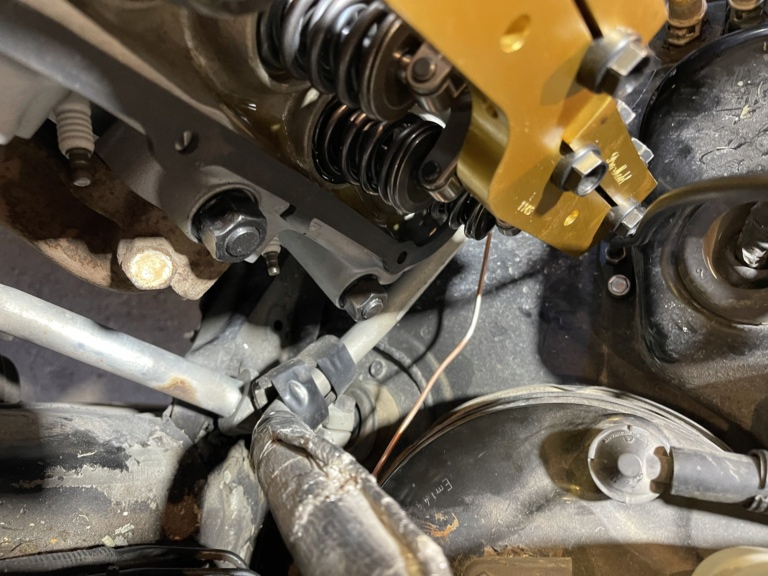

Fitting the engine/trans. From research I found that there was plenty of room for the engine to fit, but the transmission tunnel needed some opening up in certain areas. I had it in/out 3 times in total I don’t have many pics of the tunnel massaging I had to do but the servo and shift linkage area was the tightest areas.

Motor mounts. The factory mounts will work I just had to make stands that mounted to the motor. I had some 1/2” steel plate mounts that I got from an old pulling truck then took some 2x2 tubing 8” long and cut it diagonally to make 2 arms then cut the angles to match the plates and welded it all up.

Transmission mount. The factory mount set about 3” farther back than the mount on the c6 so I built a plate that bolted to the factory bracket and to the c6 mount. Engine and transmission are mounted.

I still can’t figure out how to get the pictures to stay turned the right way when they upload.

Motor mounts. The factory mounts will work I just had to make stands that mounted to the motor. I had some 1/2” steel plate mounts that I got from an old pulling truck then took some 2x2 tubing 8” long and cut it diagonally to make 2 arms then cut the angles to match the plates and welded it all up.

Transmission mount. The factory mount set about 3” farther back than the mount on the c6 so I built a plate that bolted to the factory bracket and to the c6 mount. Engine and transmission are mounted.

I still can’t figure out how to get the pictures to stay turned the right way when they upload.

Last edited by curiousgeorge on February 14th 2024, 8:19 pm; edited 1 time in total

curiousgeorge- Posts : 191

Join date : 2008-12-03

Age : 41

BigBlockRanger likes this post

Re: 06 Mustang build

Re: 06 Mustang build

I just installed the same cam in my 552! Love the build thread! Keep it up!

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

Re: 06 Mustang build

Re: 06 Mustang build

BigBlockRanger wrote:I just installed the same cam in my 552! Love the build thread! Keep it up!

Any idea how to get these pics turned right? They are fine on my phone but some turn when I upload them. I haven’t seen a way to edit them after I upload them.

curiousgeorge- Posts : 191

Join date : 2008-12-03

Age : 41

Re: 06 Mustang build

Re: 06 Mustang build

Man I have no idea. I looked at it too and I couldn't find a way to rotate.

BigBlockRanger- Posts : 1267

Join date : 2008-12-02

Age : 53

Location : Amarillo

curiousgeorge likes this post

Re: 06 Mustang build

Re: 06 Mustang build

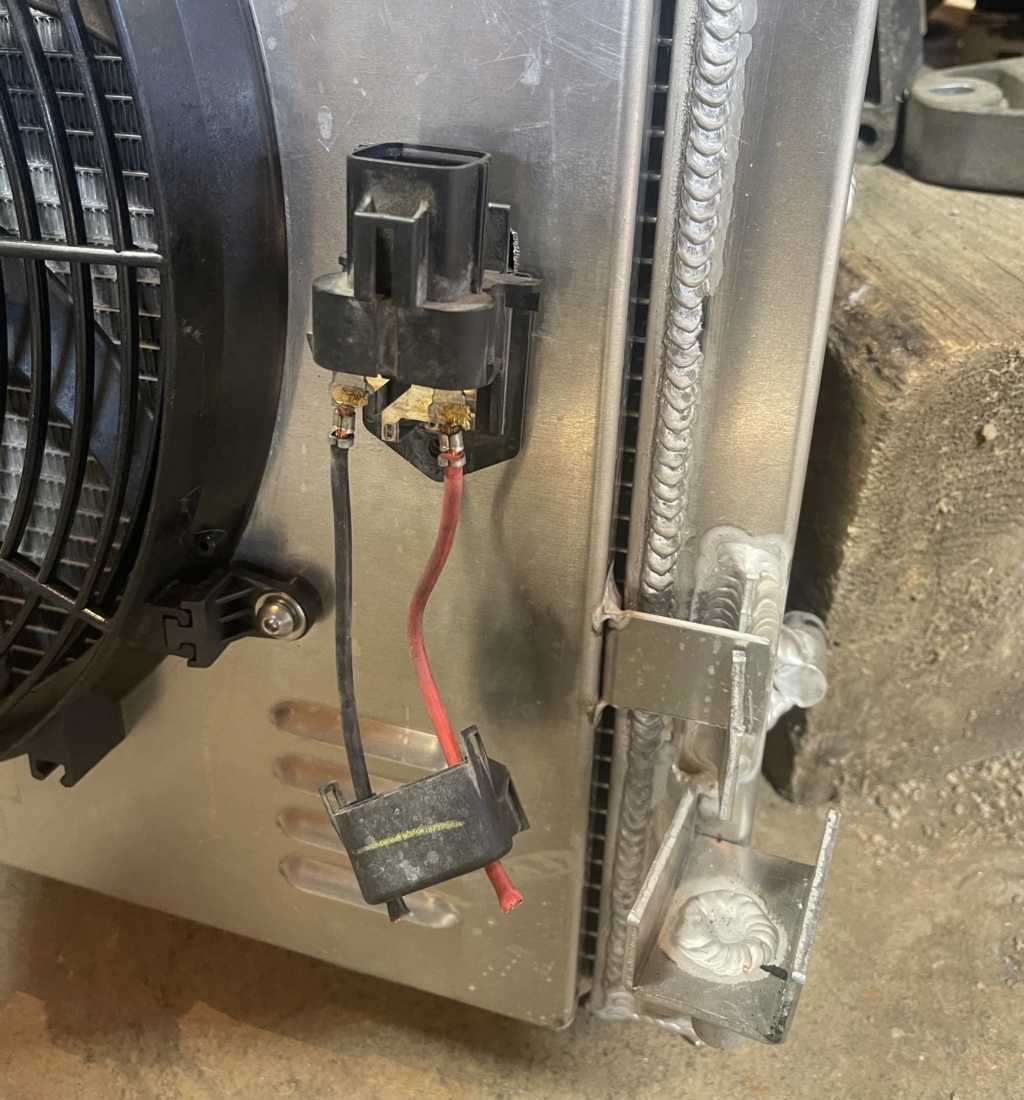

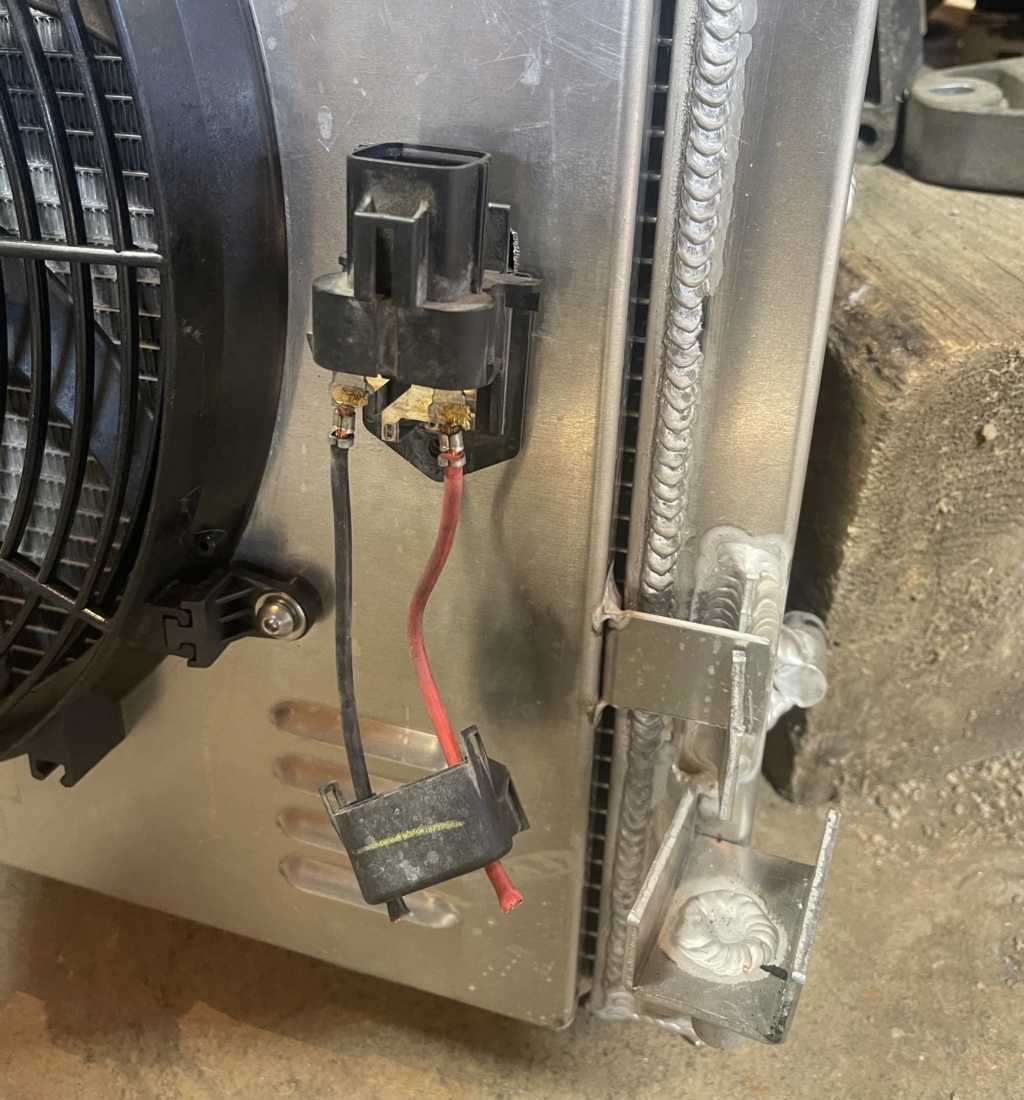

Marketplace find! I found this radiator a few weeks ago for $180 with the fan. It’s a 3 row vs the factory 1 row so hopefully it will keep things cool. I plan on using the factory temp sensor and the factory wiring to control the fan. I have hp tuner so I can adjust the on/off temps in the computer. The factory wiring has a low/high speed for the fan. It runs 12v in and 5 out for the low speed and straight thru for the high speed. I decided to do away with the capacitor since there wasn’t enough room to mount it in the shroud so I will solder the low/high tabs together so it comes on with both. This should keep it working for the A/C also. The radiator has -16 .fittings welded in and I’m going to have to put the fill cap in the top line. I may use regular hose to get everything together before I invest in all the -16 stuff. And I end up scratching those dang fittings every time I try to put them together.

curiousgeorge- Posts : 191

Join date : 2008-12-03

Age : 41

Re: 06 Mustang build

Re: 06 Mustang build

Fuel system

The car is originally fuel injection so everything had to be pulled out and replaced. I started with taking the evap and all the fuel lines out. The tank is a saddle tank and on the drivers side there is the pump and the passenger side is just a pickup and fuel level sender. This is one thing that really impressed me with the factory system. The fuel pump has a T in the pressure line and it goes to the pass side pickup and the bottom is open to the drivers side. The pump creates a vacuum on the passenger side and pulls the fuel to the drivers side where the pump wcan pick it up. I went to the pick and pull and got another passenger side pickup and drilled a hole in the top and installed a bulkhead. 1/2 nipple off the bottom of it to a T then ran 3/8 line to both pickups. Then went with -8 line to the front with an inline filter. I’m using a Holley 110gph mechanical pump and I had a pressure regulator fuel log left over from my pulling truck so I just capped the return since they say that the pump doesn’t need a return but it can have one with livery little work.

Today I started on throttle cable install. I have a cable bracket for a 4500 carb so it’s on the adapter rather than the carb but the cable seems to work fine. Since the car had drive by wire factory I’m having to get the throttle figured out I had added a piece of metal to connect the cable to but was only getting 1” of travel and I need 2 or 2-1/4 so I spent a while trying to figure out how to get more travel. I think I have it fixed but I had dinner planned with the family so I will see if it works tomorrow. The cable ended up going through the firewall right behind the valve cover and I ended up having to take it off to get the cable bolted in.

The car is originally fuel injection so everything had to be pulled out and replaced. I started with taking the evap and all the fuel lines out. The tank is a saddle tank and on the drivers side there is the pump and the passenger side is just a pickup and fuel level sender. This is one thing that really impressed me with the factory system. The fuel pump has a T in the pressure line and it goes to the pass side pickup and the bottom is open to the drivers side. The pump creates a vacuum on the passenger side and pulls the fuel to the drivers side where the pump wcan pick it up. I went to the pick and pull and got another passenger side pickup and drilled a hole in the top and installed a bulkhead. 1/2 nipple off the bottom of it to a T then ran 3/8 line to both pickups. Then went with -8 line to the front with an inline filter. I’m using a Holley 110gph mechanical pump and I had a pressure regulator fuel log left over from my pulling truck so I just capped the return since they say that the pump doesn’t need a return but it can have one with livery little work.

Today I started on throttle cable install. I have a cable bracket for a 4500 carb so it’s on the adapter rather than the carb but the cable seems to work fine. Since the car had drive by wire factory I’m having to get the throttle figured out I had added a piece of metal to connect the cable to but was only getting 1” of travel and I need 2 or 2-1/4 so I spent a while trying to figure out how to get more travel. I think I have it fixed but I had dinner planned with the family so I will see if it works tomorrow. The cable ended up going through the firewall right behind the valve cover and I ended up having to take it off to get the cable bolted in.

curiousgeorge- Posts : 191

Join date : 2008-12-03

Age : 41

BigBlockRanger likes this post

Re: 06 Mustang build

Re: 06 Mustang build

Looking good but i had to lay to the right to see the pictures straight!!

Mark Miller- Posts : 1958

Join date : 2009-09-01

Re: 06 Mustang build

Re: 06 Mustang build

Mark Miller wrote:Looking good but i had to lay to the right to see the pictures straight!!

One of these days I may figure out why they turn. They all look good when I upload them. I may try sending them to the computer and doing it that way.

curiousgeorge- Posts : 191

Join date : 2008-12-03

Age : 41

Re: 06 Mustang build

Re: 06 Mustang build

Well it looks like it is back to the drawing board on the throttle. I have tried multiple different things and the best I have gotten so far is 1/2 throttle. I think I am going to have to go to a different pedal setup that is made for a cable. I had went as far as grinding the stop on the pedal down to let it come back up farther but it just starts hitting stuff in the car. It has enough movement when it's in the vise but just can't make it work in the car. The hole between the top 2 bolts is where the cable comes through the firewall. Lets see if these pics stay the right way uploading them from the computer.

Had to add the screw sticking out of the side was my redneck way to trigger the micro switch for the nitrous.

Had to add the screw sticking out of the side was my redneck way to trigger the micro switch for the nitrous.

curiousgeorge- Posts : 191

Join date : 2008-12-03

Age : 41

Re: 06 Mustang build

Re: 06 Mustang build

That looks like it was a drive by wire throttle pedal?If so i'm not sure what other throttle pedals would work with a throttle cable!!

Mark Miller- Posts : 1958

Join date : 2009-09-01

Re: 06 Mustang build

Re: 06 Mustang build

curiousgeorge wrote:The engine

I originally planned on using the 429 then I found the block had cracked from not draining the block the last time it was ran. So I pulled the 460 I had in the corner apart only to find the block needed bored. I ended up grinding and drilling the crack and welding it then capped it with a coat of JB weld incase there were any leaks. I installed the 460 rotating assembly into the C9 block with fresh rings and bearings. Std bore -22cc dish pistons.

After about 9 months at the machine shop for a broken intake seat I finally had my heads back with M-6513-A351 springs that I removed when I bought the heads new and was ready to finish putting the engine together.

Cam is a Comp XM288H 244/254 @50 .580/.585 lift112LSA

Motorsports Victor port matched to the heads. Currently have an 830 Holley and a plate to be hooked up later.

Looks Great. Especially the Dash.

How was the Piston to Valve Clearance on Yours?

Did you put the Cam in Straight Up on the Timing Gear?

supervel45- Posts : 4498

Join date : 2013-09-04

Re: 06 Mustang build

Re: 06 Mustang build

I put it straight up and checked it. It was 1° off but I don’t remember which direction. The PTV clearance was great. Barley touched .150 of clay.

curiousgeorge- Posts : 191

Join date : 2008-12-03

Age : 41

Re: 06 Mustang build

Re: 06 Mustang build

Well after a 2 week hiatus from the shop due to ball games and trying to rebuild the transmission in my daughters car I was able to get a little work in. I ordered a billet pedal to try and get my throttle linkage working. After messing with the other one for 3-4 hours this one was done and in after about 30 minutes. I also had a pile of parts show up yesterday so I have more gauges to install and battery cable to run. Maybe I can get back to work on it somewhat regularly if I can get this dang transmission to work.

curiousgeorge- Posts : 191

Join date : 2008-12-03

Age : 41

BigBlockRanger likes this post

curiousgeorge- Posts : 191

Join date : 2008-12-03

Age : 41

BigBlockRanger likes this post

Re: 06 Mustang build

Re: 06 Mustang build

Tried mounting the battery today but I ordered the wrong box for my battery so I had to just sit it in there until I get the box. I was going to put it behind the passenger side tire but 12.5 ft of wire wouldn't reach the front so I had to move it right behind the seats. Got the wire ran and both distribution blocks mounted. 2/0 from the battery to the blocks, still need to get the ends swapped on the wires that go to the fuse panel and the ground to the block. What size wire should I run from the block to the starter? Thinking I should probably stay with 2/0 I don't think the factory 2ga is going to be heavy enough for the 460.

curiousgeorge- Posts : 191

Join date : 2008-12-03

Age : 41

BigBlockRanger and jasonf like this post

curiousgeorge- Posts : 191

Join date : 2008-12-03

Age : 41

BigBlockRanger and Mark Miller like this post

Re: 06 Mustang build

Re: 06 Mustang build

No pics today but I did get my ground cable fixed and heard the engine turn over with the starter. It won’t crank with the key so either the pats or the neutral safety switch is keeping it from getting fire. I’ll take my laptop out there and turn the pats off and see if that helps. If not I’ll have to find the wires and bypass the NSS.

curiousgeorge- Posts : 191

Join date : 2008-12-03

Age : 41

Re: 06 Mustang build

Re: 06 Mustang build

curiousgeorge wrote:Fuel system

The car is originally fuel injection so everything had to be pulled out and replaced. I started with taking the evap and all the fuel lines out. The tank is a saddle tank and on the drivers side there is the pump and the passenger side is just a pickup and fuel level sender. This is one thing that really impressed me with the factory system. The fuel pump has a T in the pressure line and it goes to the pass side pickup and the bottom is open to the drivers side. The pump creates a vacuum on the passenger side and pulls the fuel to the drivers side where the pump wcan pick it up. I went to the pick and pull and got another passenger side pickup and drilled a hole in the top and installed a bulkhead. 1/2 nipple off the bottom of it to a T then ran 3/8 line to both pickups. Then went with -8 line to the front with an inline filter. I’m using a Holley 110gph mechanical pump and I had a pressure regulator fuel log left over from my pulling truck so I just capped the return since they say that the pump doesn’t need a return but it can have one with livery little work.

Today I started on throttle cable install. I have a cable bracket for a 4500 carb so it’s on the adapter rather than the carb but the cable seems to work fine. Since the car had drive by wire factory I’m having to get the throttle figured out I had added a piece of metal to connect the cable to but was only getting 1” of travel and I need 2 or 2-1/4 so I spent a while trying to figure out how to get more travel. I think I have it fixed but I had dinner planned with the family so I will see if it works tomorrow. The cable ended up going through the firewall right behind the valve cover and I ended up having to take it off to get the cable bolted in.

I would be afraid to run and drive with that throttle linkage with that much angle from the carb to the bracket!!

Mark Miller- Posts : 1958

Join date : 2009-09-01

Re: 06 Mustang build

Re: 06 Mustang build

Mark Miller wrote:curiousgeorge wrote:Fuel system

The car is originally fuel injection so everything had to be pulled out and replaced. I started with taking the evap and all the fuel lines out. The tank is a saddle tank and on the drivers side there is the pump and the passenger side is just a pickup and fuel level sender. This is one thing that really impressed me with the factory system. The fuel pump has a T in the pressure line and it goes to the pass side pickup and the bottom is open to the drivers side. The pump creates a vacuum on the passenger side and pulls the fuel to the drivers side where the pump wcan pick it up. I went to the pick and pull and got another passenger side pickup and drilled a hole in the top and installed a bulkhead. 1/2 nipple off the bottom of it to a T then ran 3/8 line to both pickups. Then went with -8 line to the front with an inline filter. I’m using a Holley 110gph mechanical pump and I had a pressure regulator fuel log left over from my pulling truck so I just capped the return since they say that the pump doesn’t need a return but it can have one with livery little work.

Today I started on throttle cable install. I have a cable bracket for a 4500 carb so it’s on the adapter rather than the carb but the cable seems to work fine. Since the car had drive by wire factory I’m having to get the throttle figured out I had added a piece of metal to connect the cable to but was only getting 1” of travel and I need 2 or 2-1/4 so I spent a while trying to figure out how to get more travel. I think I have it fixed but I had dinner planned with the family so I will see if it works tomorrow. The cable ended up going through the firewall right behind the valve cover and I ended up having to take it off to get the cable bolted in.

I would be afraid to run and drive with that throttle linkage with that much angle from the carb to the bracket!!

I have moved the cable to the lower hole in the carb and shimmed the cable mount up some to make it straighter.

curiousgeorge- Posts : 191

Join date : 2008-12-03

Age : 41

Mark Miller likes this post

Re: 06 Mustang build

Re: 06 Mustang build

Not much of an update been too busy chasing the kids to work on the car. But today I scored a fiberglass cowl hood off marketplace for about 1/2price of new. I forgot to get pics but I’ll update with some when I unload it tomorrow.

curiousgeorge- Posts : 191

Join date : 2008-12-03

Age : 41

curiousgeorge- Posts : 191

Join date : 2008-12-03

Age : 41

BigBlockRanger likes this post

Page 1 of 4 • 1, 2, 3, 4

Similar topics

Similar topics» My 98 Mustang build

» Bruno's 87 Mustang build

» My 94 Mustang build

» My first mustang build

» 73 mustang 528 build

» Bruno's 87 Mustang build

» My 94 Mustang build

» My first mustang build

» 73 mustang 528 build

Page 1 of 4

Permissions in this forum:

You cannot reply to topics in this forum