Fox Frame Conectors

4 posters

Page 1 of 1

Fox Frame Conectors

Fox Frame Conectors

I purchased some steel to make frame conectors.

I know that the front and rear sub frames don't exactly line up. Are you guys cutting a diagnal slot in the floor to line up the two frames?

Or are you Zig in the frame conector to line them up or what?

I looked at Auto Weld Chassis sight and it doesent say if the cut in the floor is diaginal or if it runs paralell to the frames.

Any help would be great.

I know that the front and rear sub frames don't exactly line up. Are you guys cutting a diagnal slot in the floor to line up the two frames?

Or are you Zig in the frame conector to line them up or what?

I looked at Auto Weld Chassis sight and it doesent say if the cut in the floor is diaginal or if it runs paralell to the frames.

Any help would be great.

racerk_2000- Posts : 88

Join date : 2009-01-04

Re: Fox Frame Conectors

Re: Fox Frame Conectors

What size steel?

Yes, it runs slightly on an angle.......easiest is to cut the front subframe off completely, flush with the floor, just before the bend (maybe 4-5" ??) , where it necks wider.....then cut thru the floor on an angle, laying the new 2" subframe in the front existing subframe, and to the rear subframe, flush with the bottom, as well. (have to trim the rear in an arc to fit)

Yes, it runs slightly on an angle.......easiest is to cut the front subframe off completely, flush with the floor, just before the bend (maybe 4-5" ??) , where it necks wider.....then cut thru the floor on an angle, laying the new 2" subframe in the front existing subframe, and to the rear subframe, flush with the bottom, as well. (have to trim the rear in an arc to fit)

feetfirst- Posts : 139

Join date : 2009-10-30

Location : Ontario, Canada

Re: Fox Frame Conectors

Re: Fox Frame Conectors

Kevin,

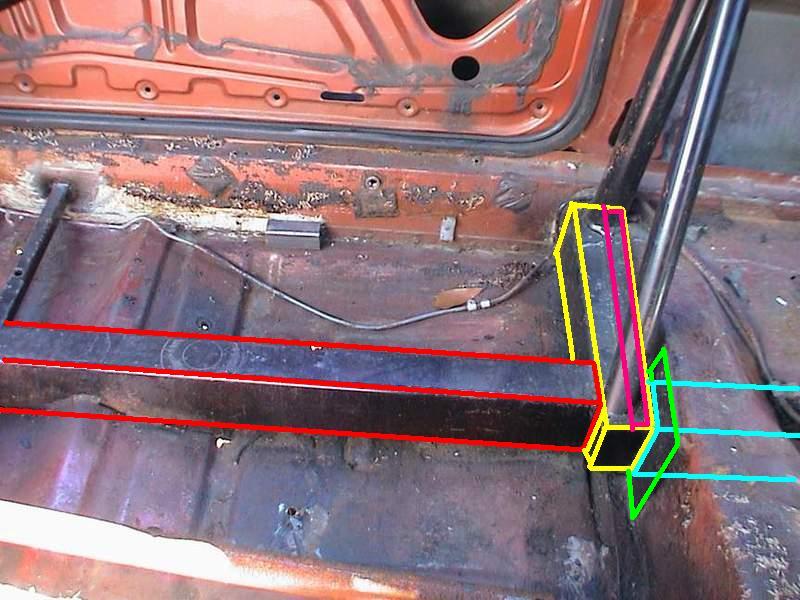

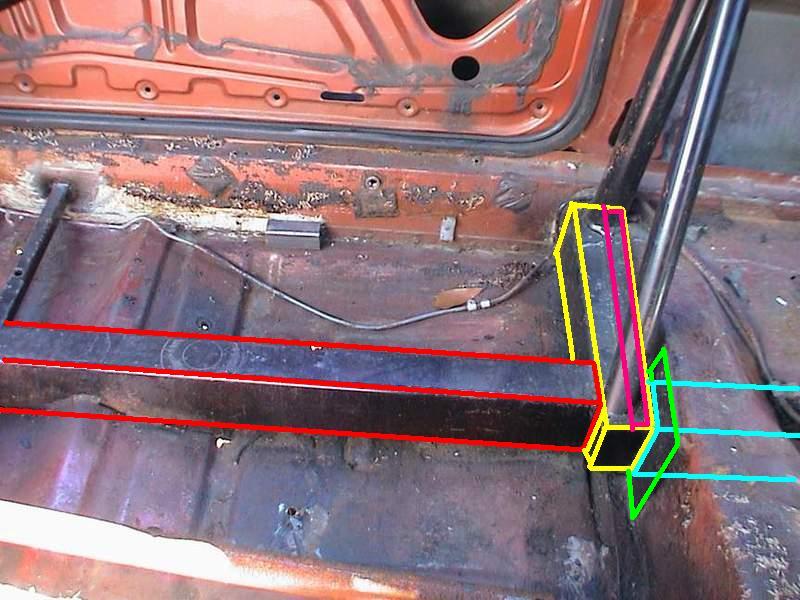

Easiest way I've found (I've done it to two cars) is to cut the floor off of the top of the front subframe. You can lay some 2x2 in there. It'll sit about 1/2" - 3/4" higher than the floor. Run this back to the front seat support (the raised piece that the front of the seat bolts to. At that point weld on some 2x3 and continue it to the back... This is the red piece in the pic.

Now at the back what I've done is to cut open the front of the rear subframe. It basically opens into the rear pass footwell area.

Shove some 2x3 in there. Shove it far enough back to line up and bolt into the lower control arm hole if you like. This is the light blue piece in the pic. Run this piece of 2x3 out enough to weld to another piece of 2x3 that is welded from the rocker to the piece that runs into the rear subframe. This is the yellow piece. The yellow piece is welded to the rear floor kickup. It also has some plate on the top (maybe 1.5" wide) to help fill the gap from the 2x3 to the kickup. The purple piece is this plate. The green piece is some plate that was cut and welded to cover and strengthen the hole where the blue piece go into the rear subframe.

Look at this pic and see if it all makes sense. If not send me a PM with your number and I'll give you a call.

Easiest way I've found (I've done it to two cars) is to cut the floor off of the top of the front subframe. You can lay some 2x2 in there. It'll sit about 1/2" - 3/4" higher than the floor. Run this back to the front seat support (the raised piece that the front of the seat bolts to. At that point weld on some 2x3 and continue it to the back... This is the red piece in the pic.

Now at the back what I've done is to cut open the front of the rear subframe. It basically opens into the rear pass footwell area.

Shove some 2x3 in there. Shove it far enough back to line up and bolt into the lower control arm hole if you like. This is the light blue piece in the pic. Run this piece of 2x3 out enough to weld to another piece of 2x3 that is welded from the rocker to the piece that runs into the rear subframe. This is the yellow piece. The yellow piece is welded to the rear floor kickup. It also has some plate on the top (maybe 1.5" wide) to help fill the gap from the 2x3 to the kickup. The purple piece is this plate. The green piece is some plate that was cut and welded to cover and strengthen the hole where the blue piece go into the rear subframe.

Look at this pic and see if it all makes sense. If not send me a PM with your number and I'll give you a call.

jbozzelle- Posts : 3705

Join date : 2009-08-10

Age : 50

Location : New Orleans

Re: Fox Frame Conectors

Re: Fox Frame Conectors

Thanks guys for the ideas. I wanted to get more work done today but mother nature has had her way with middle America. We have had extensive flooding here in Tennessee as well as Tornados here and in Texas, Arkansas and Oaklahoma.

I hope that everyone is ok.

I hope that everyone is ok.

racerk_2000- Posts : 88

Join date : 2009-01-04

Re: Fox Frame Conectors

Re: Fox Frame Conectors

racerk_2000 wrote:Thanks guys for the ideas. I wanted to get more work done today but mother nature has had her way with middle America. We have had extensive flooding here in Tennessee as well as Tornados here and in Texas, Arkansas and Oaklahoma.

I hope that everyone is ok.

Keep your pant legs rolled up and be safe!!

Bill

billandlori- Posts : 2081

Join date : 2009-08-06

Age : 55

Location : Stratford, Ontario, Canada

Re: Fox Frame Conectors

Re: Fox Frame Conectors

billandlori wrote:racerk_2000 wrote:Thanks guys for the ideas. I wanted to get more work done today but mother nature has had her way with middle America. We have had extensive flooding here in Tennessee as well as Tornados here and in Texas, Arkansas and Oaklahoma.

I hope that everyone is ok.

Keep your pant legs rolled up and be safe!!

Bill

Yeah. Power tools and flood waters don't mix well.

jbozzelle- Posts : 3705

Join date : 2009-08-10

Age : 50

Location : New Orleans

Similar topics

Similar topics» need some more parts !

» 55 staight axle swap 02 ranger ifs donor truck

» Another Sub-Frame Question!!!

» Sub frame connectors

» sub frame connectors

» 55 staight axle swap 02 ranger ifs donor truck

» Another Sub-Frame Question!!!

» Sub frame connectors

» sub frame connectors

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum