The beginning of the next project.

+12

David Willingham

KY JELLY

David Cole

jones

dfree383

70429scj

DILLIGASDAVE

IDT-572

cool40

Race Ready Fabrications

bosshoss

Doug Rahn

16 posters

Page 1 of 2

Page 1 of 2 • 1, 2

The beginning of the next project.

The beginning of the next project.

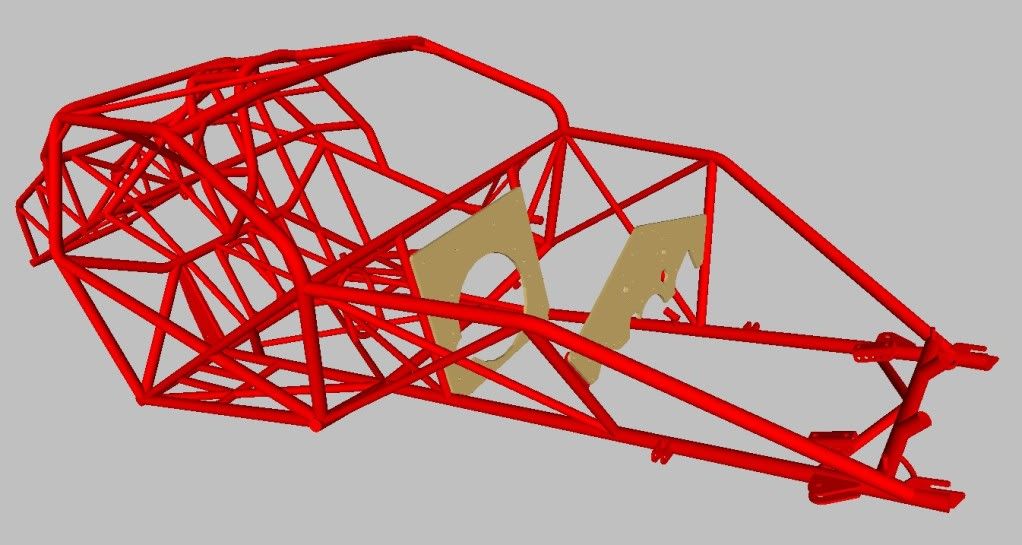

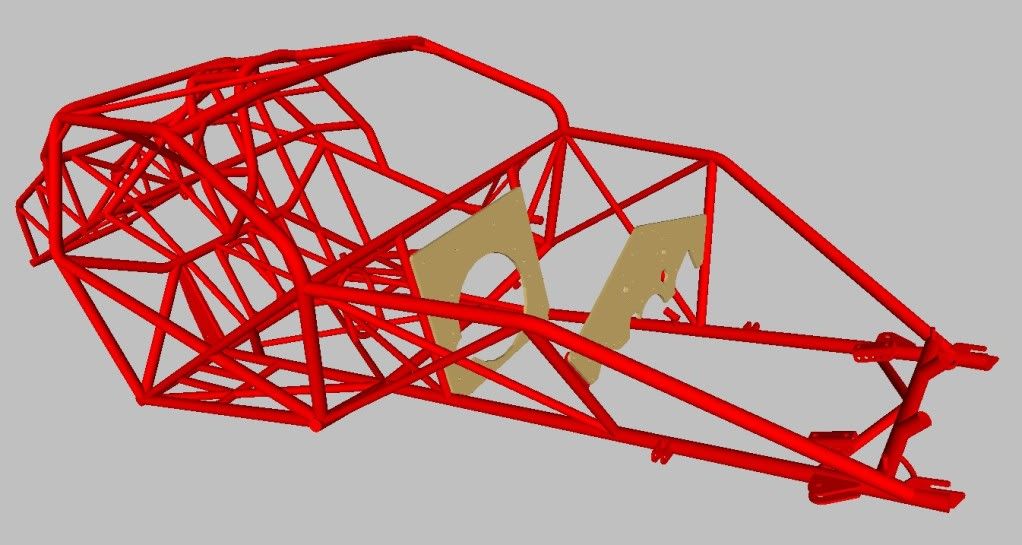

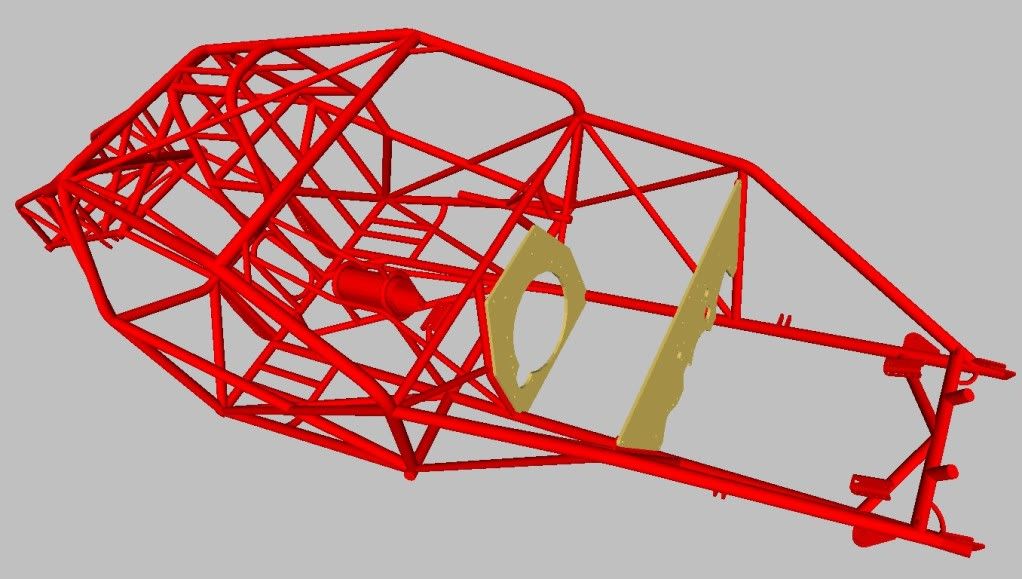

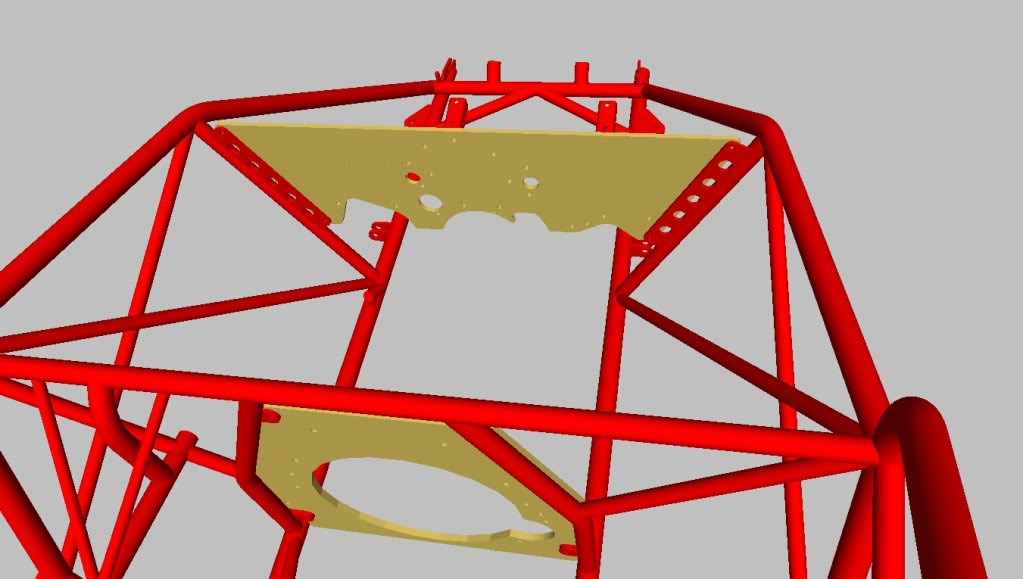

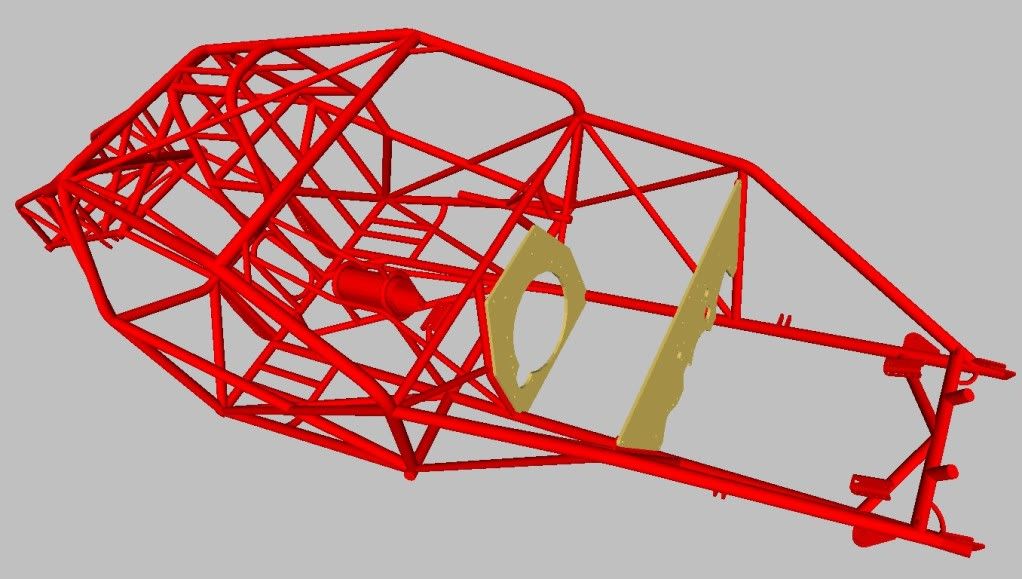

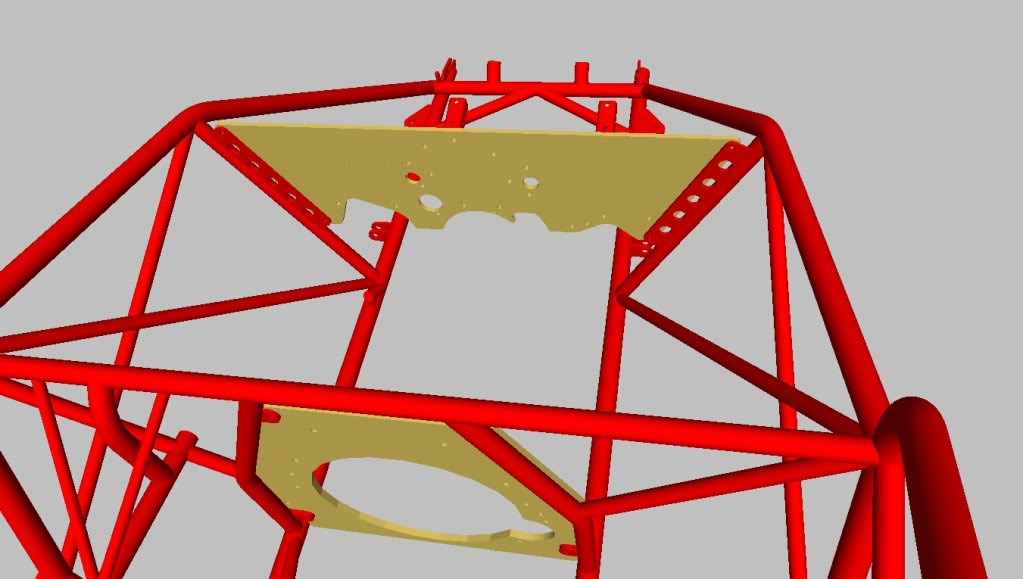

About 20 years ago I bought a '65 Mustang Fastback that's been sitting in my shop collecting dust. Well, I've finally decided which direction this project is going.

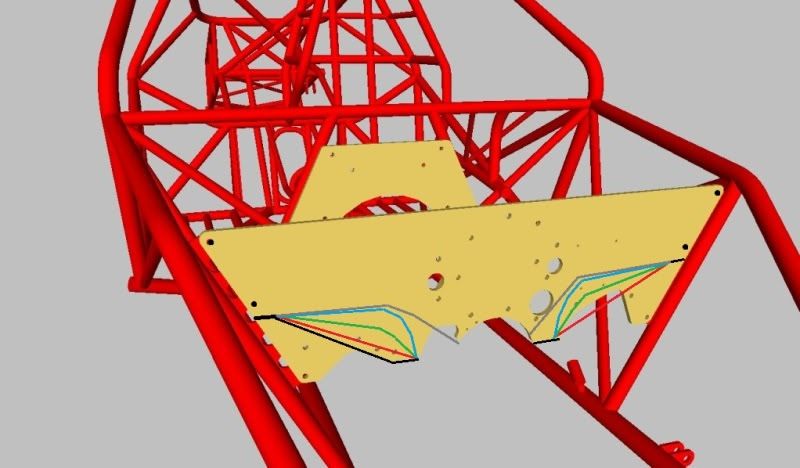

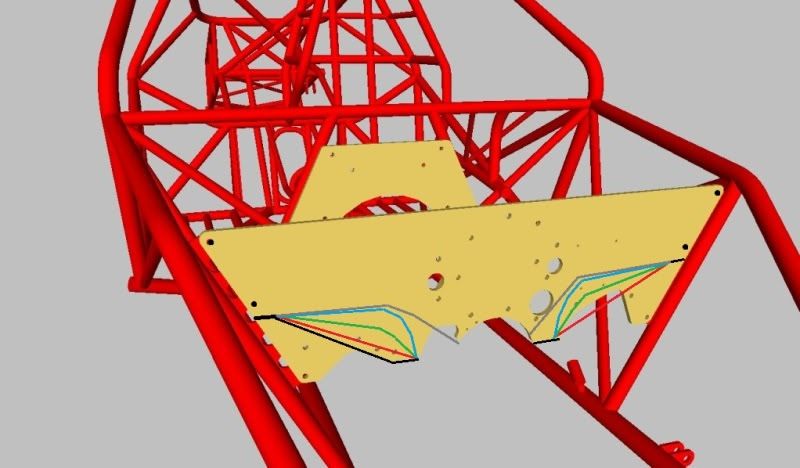

An all chromoly tube chassis powered by a big block Ford of coarse. This is definitely a long term project and I hope I'm around long enough to finish it. I finished the drawing for the chassis last night in my BendTech Pro program, the next thing is to build a chassis table to build it on. Should be a lot of fun .

.

An all chromoly tube chassis powered by a big block Ford of coarse. This is definitely a long term project and I hope I'm around long enough to finish it. I finished the drawing for the chassis last night in my BendTech Pro program, the next thing is to build a chassis table to build it on. Should be a lot of fun

Re: The beginning of the next project.

Re: The beginning of the next project.

Wow Doug that is some very nice work right there. Looks awesome. I have been thinking about upgrading my Bend Tech EZ program that looks very cool from here. Dont forget to add the Kidney bar on the driver side. Looks like the engine is way back there should be a way cool ride when done.

dkp

dkp

bosshoss- BBF CONTRIBUTOR

- Posts : 499

Join date : 2009-08-10

Re: The beginning of the next project.

Re: The beginning of the next project.

Very very cool....65 fastback is one of my all time favorites.

Race Ready Fabrications- Posts : 619

Join date : 2010-04-19

Age : 44

Location : Chandler, IN

Re: The beginning of the next project.

Re: The beginning of the next project.

sell the fastback and buy a race car.the old cars will bring some good $$ and you could do a glass body if you realy want the look.

cool40- BBF CONTRIBUTOR

- Posts : 7313

Join date : 2009-08-31

Age : 53

Location : on the 1/8 mile dyno

Re: The beginning of the next project.

Re: The beginning of the next project.

bosshoss wrote:Wow Doug that is some very nice work right there. Looks awesome. I have been thinking about upgrading my Bend Tech EZ program that looks very cool from here. Dont forget to add the Kidney bar on the driver side. Looks like the engine is way back there should be a way cool ride when done.

dkp

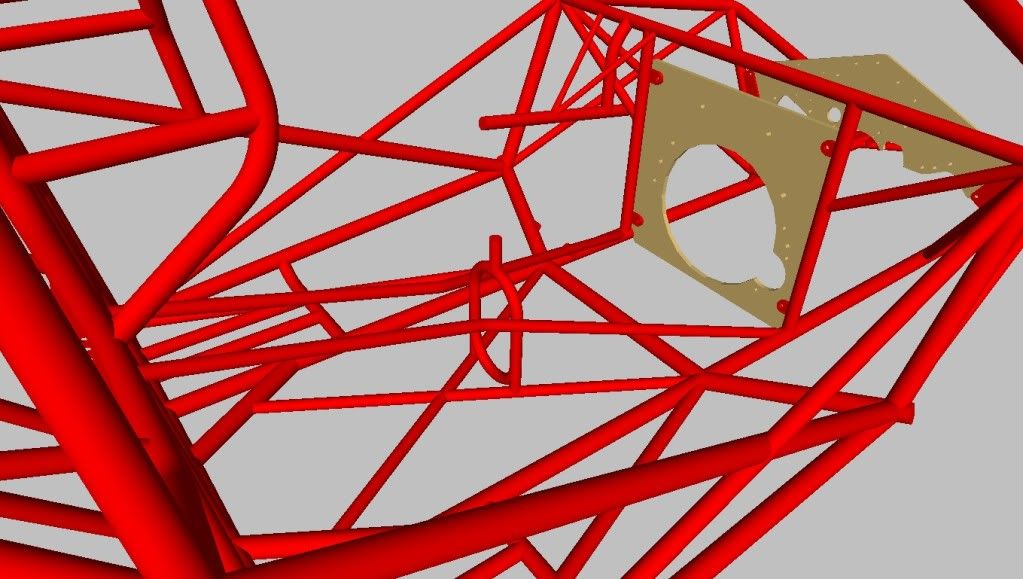

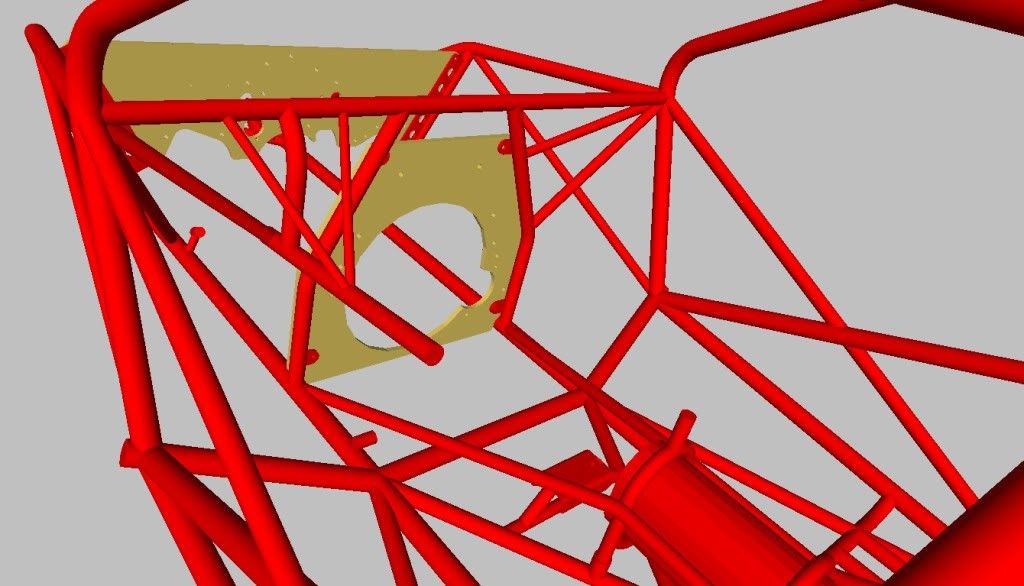

Thanks, I missed that one. I just upgrade my older version of BendTech Pro from 4.0.03 to the new 5.01.02 and they made me a good deal on their new BendTech SM program module (Plate & Sheetmetal). After you draw up a plate or sheetmetal part you can intergrate it into the tube program, very cool

Re: The beginning of the next project.

Re: The beginning of the next project.

Cool Doug I'm doing the same thing...................  But I couldn't bring myself to using my 66 Fastback, I'm going fiberglass body

But I couldn't bring myself to using my 66 Fastback, I'm going fiberglass body  Ky and I are going to make a mold off of my car.

Ky and I are going to make a mold off of my car.

IDT-572- BBF CONTRIBUTOR

- Posts : 4628

Join date : 2008-12-02

Age : 63

Location : Shelbyville Tn.

Re: The beginning of the next project.

Re: The beginning of the next project.

Looks good Doug.

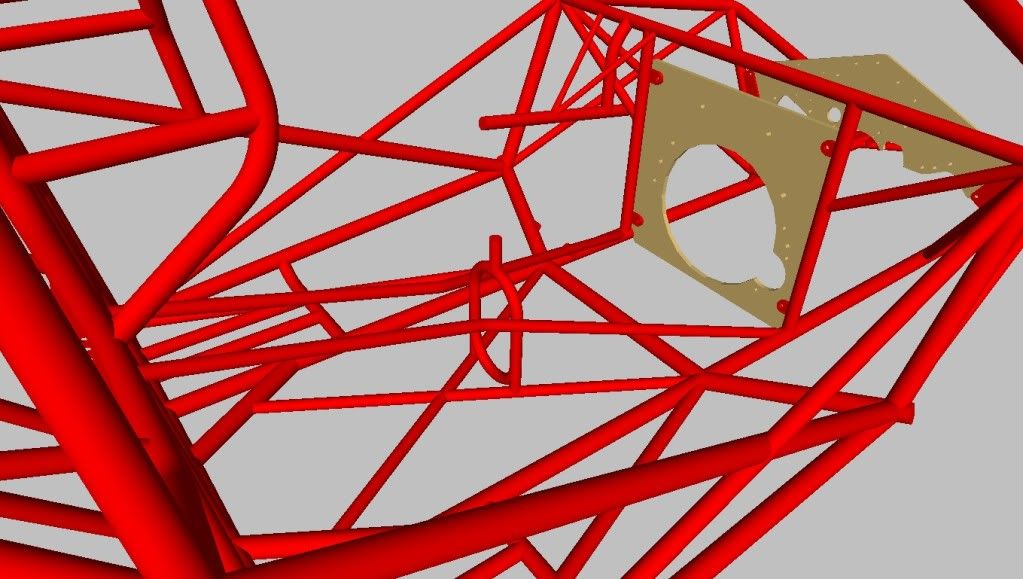

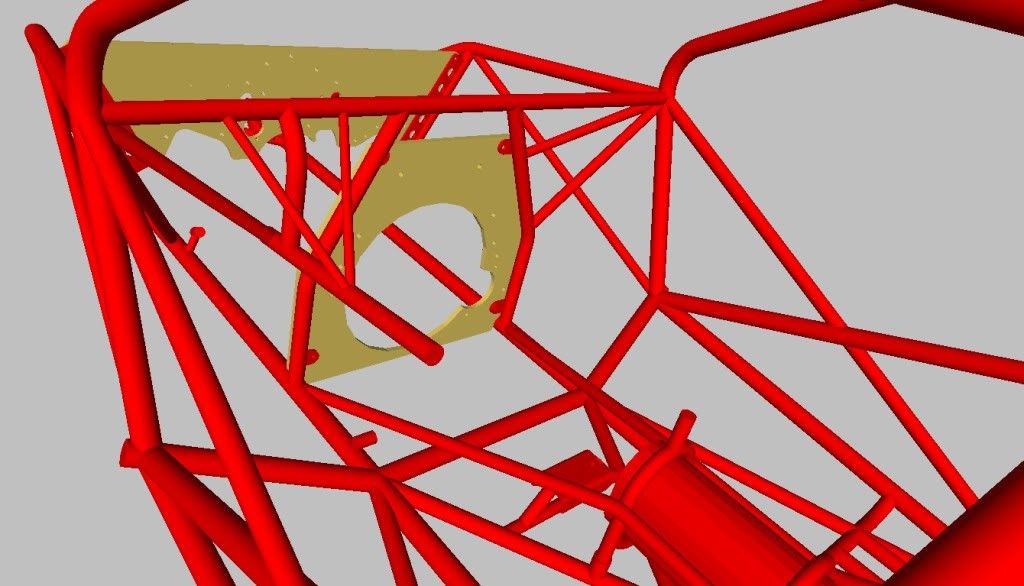

It looks like you did some in depth research & ended up with a nice mix of influences from some of the better chassis shops out there. What size slicks are you planning on using. The 65 Mustang should be easier to fit slicks/tubs higher up inside the body than say a 69/70 Mustang is.

One thing I would change is making the front motor plate flat/flatter across the top & move the mounting brackets/bolts higher up, instead of dipping down each side. That way the motor plate will attach to the uprights as close to the top as possible instead of in the center of the uprights. Doing this better supports the top strut mounts & reduces the chance of cracking/breaking the unsupported middle of the upright tubing.

Also don't forget two add the small diagonals to help support the rear bumper crossmember at the 'chute tether mount area.

It looks like you did some in depth research & ended up with a nice mix of influences from some of the better chassis shops out there. What size slicks are you planning on using. The 65 Mustang should be easier to fit slicks/tubs higher up inside the body than say a 69/70 Mustang is.

One thing I would change is making the front motor plate flat/flatter across the top & move the mounting brackets/bolts higher up, instead of dipping down each side. That way the motor plate will attach to the uprights as close to the top as possible instead of in the center of the uprights. Doing this better supports the top strut mounts & reduces the chance of cracking/breaking the unsupported middle of the upright tubing.

Also don't forget two add the small diagonals to help support the rear bumper crossmember at the 'chute tether mount area.

DILLIGASDAVE- Posts : 2262

Join date : 2009-08-08

Location : Texas. pronounced "texASS"

Clean

Clean

Doug,

I use autocad and soild works every day but I don't get to do anything as cool as what you have done. Good luck and be persistant with finishing it.

I use autocad and soild works every day but I don't get to do anything as cool as what you have done. Good luck and be persistant with finishing it.

70429scj- Posts : 348

Join date : 2009-08-07

Re: The beginning of the next project.

Re: The beginning of the next project.

Nice Model Doug !! Does it actual do the design and stress calcs too?

dfree383- BBF CONTRIBUTOR

- Posts : 14851

Join date : 2009-07-09

Location : Home Wif Da Wife.....

Re: The beginning of the next project.

Re: The beginning of the next project.

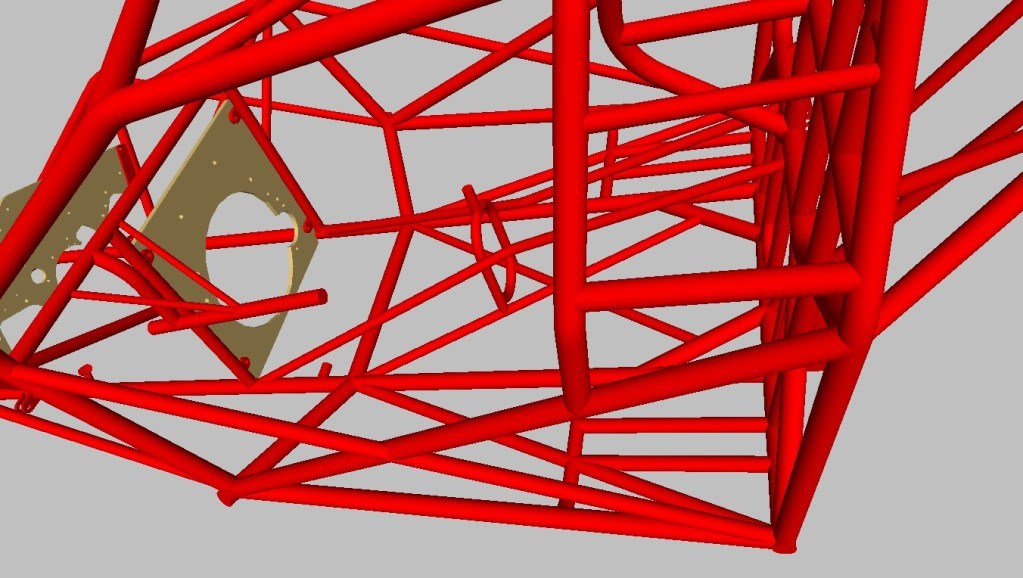

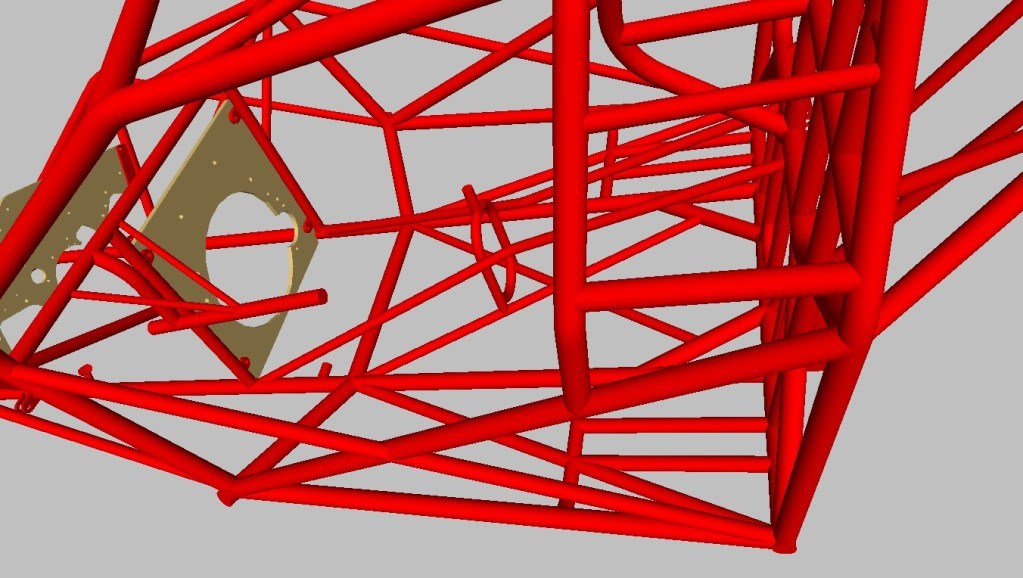

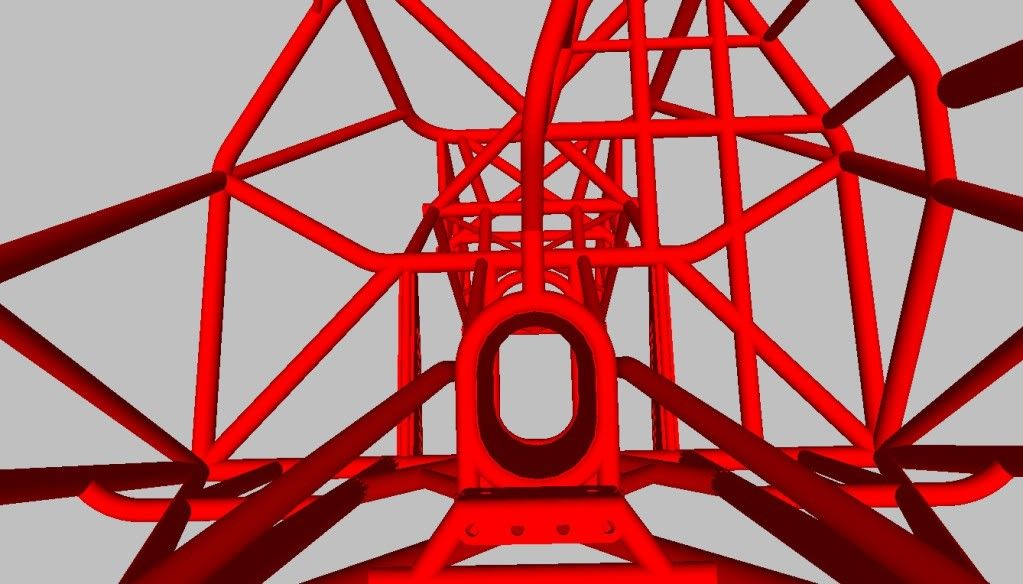

Why is the foot well area kicked up, exhaust clearance or structural? Looks like a tight fit in that area.

jones- Posts : 2230

Join date : 2008-12-02

Location : Philadelphia, MS.

Re: The beginning of the next project.

Re: The beginning of the next project.

Thanks, I thought about going fiberglass, but I also like the idea of using an original body. It's still early and things do change.IDT-572 wrote:Cool Doug I'm doing the same thing...................But I couldn't bring myself to using my 66 Fastback, I'm going fiberglass body

Ky and I are going to make a mold off of my car.

Thanks, 90% of it is from a Jerry Bickel blueprint. The motorplate in the drawing is my current one in the '90 Mustang, I just threw it in there for looks. Thanks for the tips, that's why I like this forum, more eyes to catch things.DILLIGASDAVE wrote:Looks good Doug.

It looks like you did some in depth research & ended up with a nice mix of influences from some of the better chassis shops out there. What size slicks are you planning on using. The 65 Mustang should be easier to fit slicks/tubs higher up inside the body than say a 69/70 Mustang is.

One thing I would change is making the front motor plate flat/flatter across the top & move the mounting brackets/bolts higher up, instead of dipping down each side. That way the motor plate will attach to the uprights as close to the top as possible instead of in the center of the uprights. Doing this better supports the top strut mounts & reduces the chance of cracking/breaking the unsupported middle of the upright tubing.

Also don't forget two add the small diagonals to help support the rear bumper crossmember at the 'chute tether mount area.

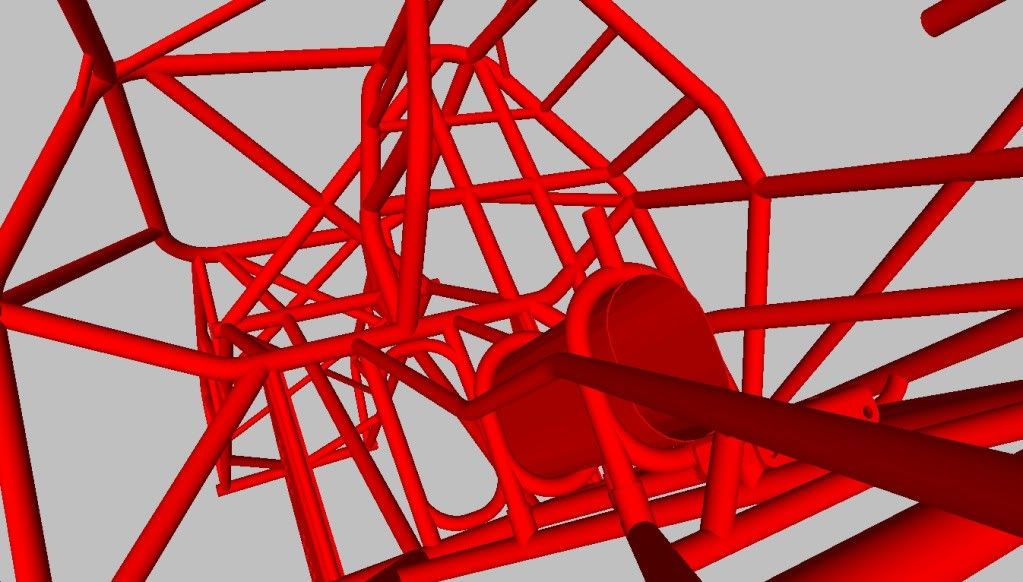

If you have a CNC bender it will do that for you and you can print copies of the cuts to wrap around the tube to mark the coping. It doesn't do stress calculations but it will calculate the total weight if you put the information in the material library. Not including the brackets, plates, welding, etc. it weighs in at 257lbs. in tubing alone.dfree383 wrote:Nice Model Doug !! Does it actual do the design and stress calcs too?

Re: The beginning of the next project.

Re: The beginning of the next project.

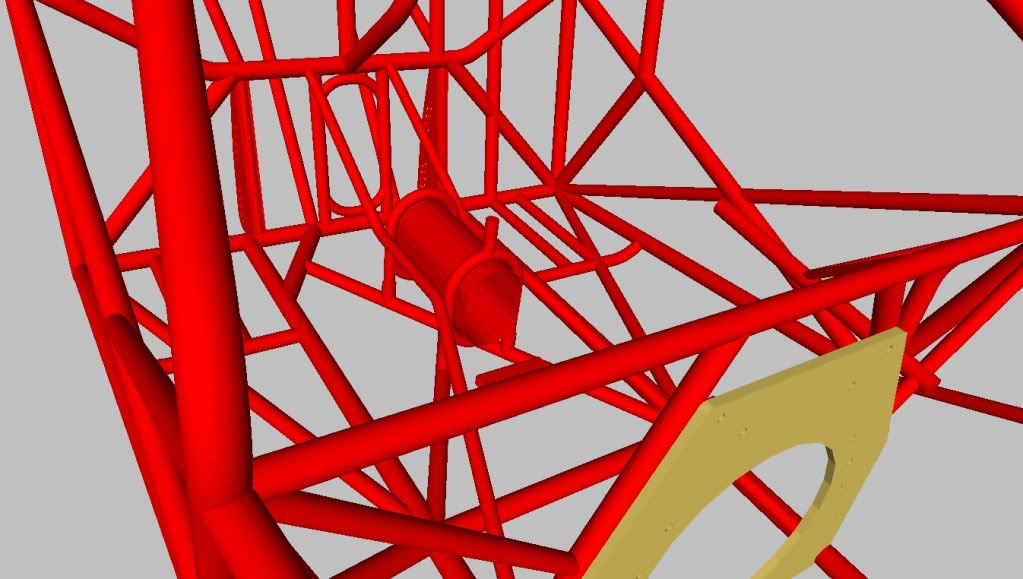

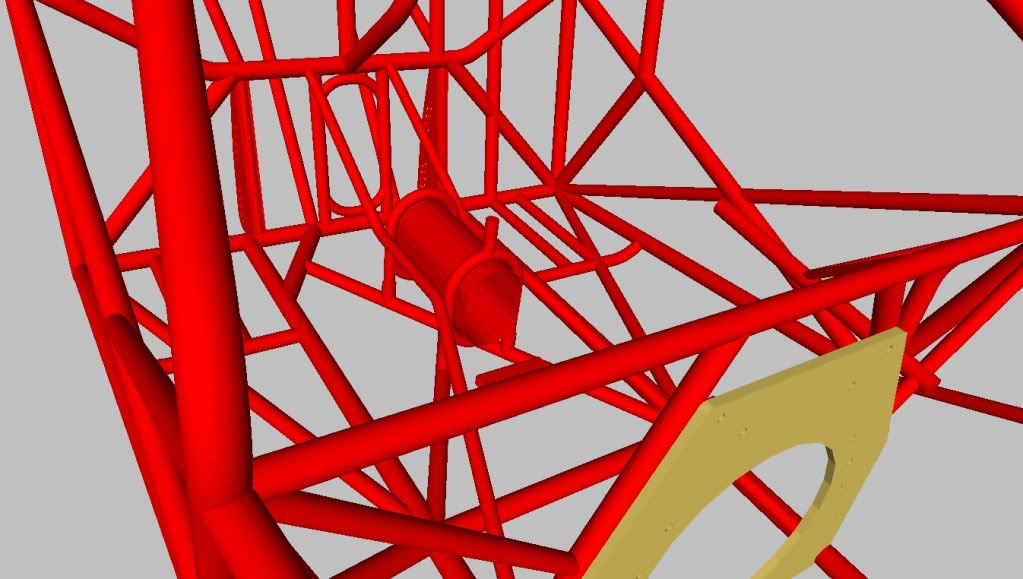

jones wrote:Why is the foot well area kicked up, exhaust clearance or structural? Looks like a tight fit in that area.

Header clearance. Actually the footwell area is almost 14 inches across right at the firewall.

Re: The beginning of the next project.

Re: The beginning of the next project.

Like Doug said the floor kickup helps increase header collector/muffler collector room under low slung cars where the main frame rails might only be 3.5 to 4" off the ground.Doug Rahn wrote:jones wrote:Why is the foot well area kicked up, exhaust clearance or structural? Looks like a tight fit in that area.

Header clearance. Actually the footwell area is almost 14 inches across right at the firewall.

On cars that have zoomies, and/or the header collector exiting through/under the front fenders, the front floor kickup isn't a necessity. And the kickup isn't as important on cars that have a real short driver compartment combined with a real long front fender (like a P/M 115" wb early vette body) where the header collector might end up sitting a long ways away from the front floor/firewall area.

But even if say a zoomie is used & the floor kickup isn't really needed, using a kickup anyway can still sometimes be a good idea for future resale value cuz the car will fit more engine/header combos. Plus the higher the front floor kickup is, you end up using a little less of the 1-5/8" tubing in the car (it's not a butt load less big tubing, but every ounce counts).

DILLIGASDAVE- Posts : 2262

Join date : 2009-08-08

Location : Texas. pronounced "texASS"

Re: The beginning of the next project.

Re: The beginning of the next project.

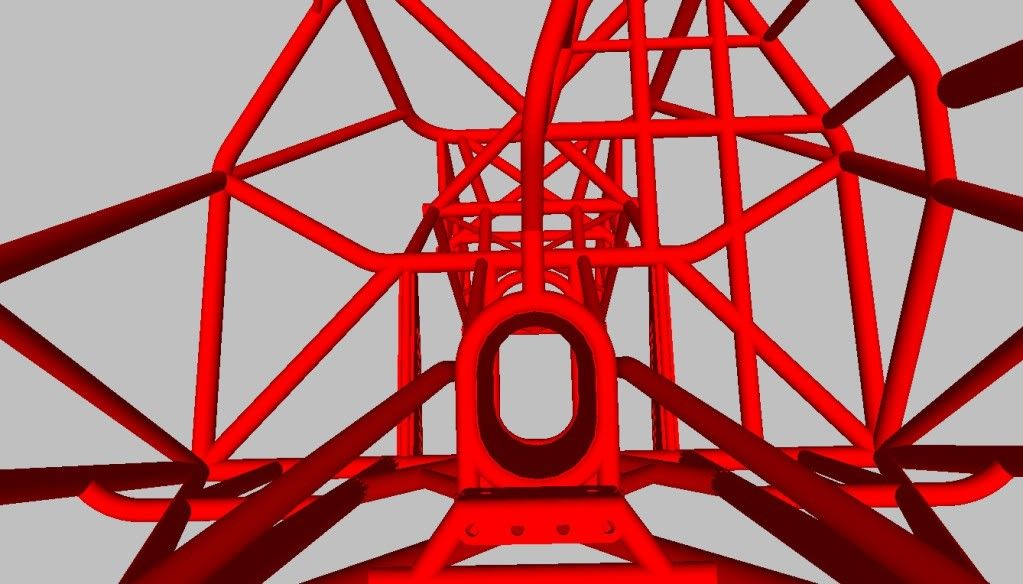

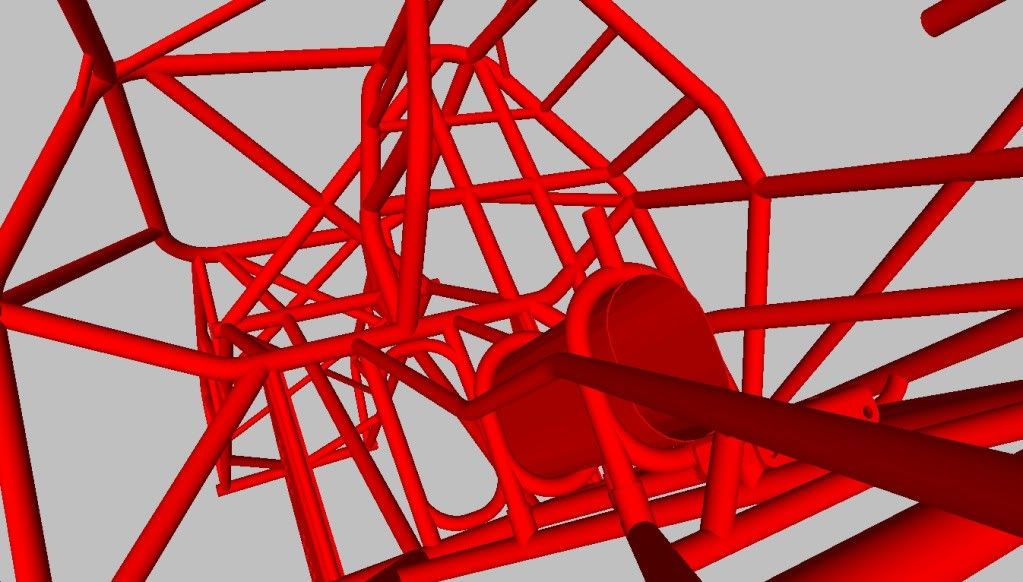

I did notice at the Ennis ADRL event that Bickel has changed up how he does some of the rear bars (from the main hoop back) to make the back of his cars more rigid. But if you're not going to be using a power adder, your current design should be good.Doug Rahn wrote:...........90% of it is from a Jerry Bickel blueprint................

DILLIGASDAVE- Posts : 2262

Join date : 2009-08-08

Location : Texas. pronounced "texASS"

Re: The beginning of the next project.

Re: The beginning of the next project.

Looks great!

One new item from a rule revision that you might want to plan into the design is the new driveshaft tube. It's not just loops any longer. From the rule revisions for advanced ET:

Page 10

DRIVETRAIN: 2

DRIVELINE (December 13, 2010)

Beginning Jan. 1, 2012 all full-bodied vehicles, where the OEM floor has been

removed, each end of driveshaft must have round 360-degree driveshaft loops

within 6 inches of U-joints. Additionally, driveshaft must be covered by 360-

degree tube, covering the front U-joint and extending rearward a minimum 12

inches. Minimum thickness of tube is .050-inch chromoly or titanium. Driveshaft

tube must utilize a minimum of four attachment points to the chassis, either

bolted with minimum 5/16 SAE bolts or welded or 1/4-inch push/pull pins. See

General Regulations 2:4.

SECTION

One new item from a rule revision that you might want to plan into the design is the new driveshaft tube. It's not just loops any longer. From the rule revisions for advanced ET:

Page 10

DRIVETRAIN: 2

DRIVELINE (December 13, 2010)

Beginning Jan. 1, 2012 all full-bodied vehicles, where the OEM floor has been

removed, each end of driveshaft must have round 360-degree driveshaft loops

within 6 inches of U-joints. Additionally, driveshaft must be covered by 360-

degree tube, covering the front U-joint and extending rearward a minimum 12

inches. Minimum thickness of tube is .050-inch chromoly or titanium. Driveshaft

tube must utilize a minimum of four attachment points to the chassis, either

bolted with minimum 5/16 SAE bolts or welded or 1/4-inch push/pull pins. See

General Regulations 2:4.

SECTION

Re: The beginning of the next project.

Re: The beginning of the next project.

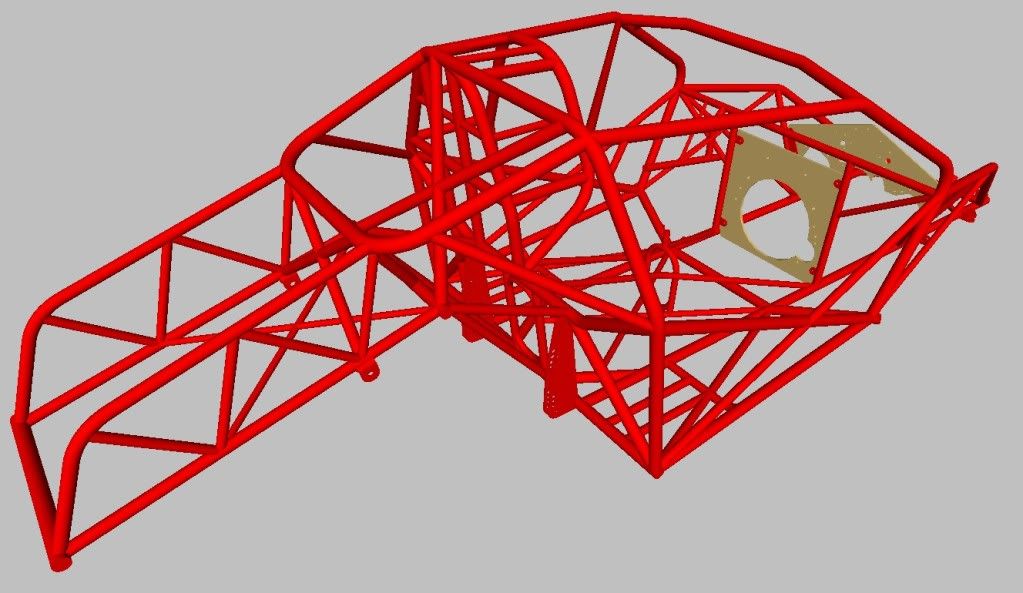

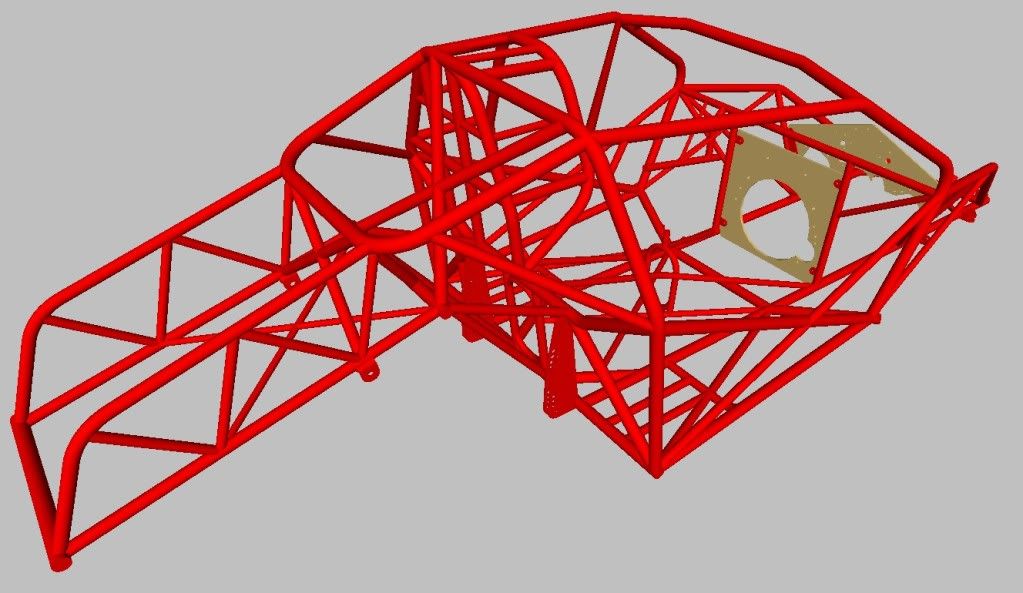

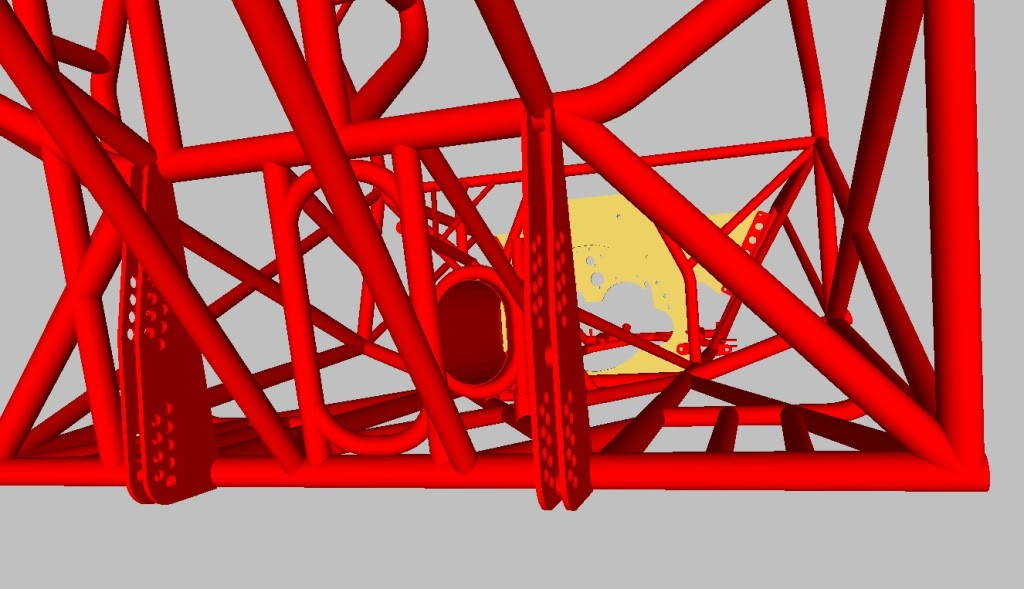

How far is the back of the engine from the center of the axle that looks a tad far back from the drawing.

KY JELLY- Posts : 1530

Join date : 2008-12-03

Re: The beginning of the next project.

Re: The beginning of the next project.

David Cole wrote:Looks great!

One new item from a rule revision that you might want to plan into the design is the new driveshaft tube. It's not just loops any longer. From the rule revisions for advanced ET:

Page 10

DRIVETRAIN: 2

DRIVELINE (December 13, 2010)

Beginning Jan. 1, 2012 all full-bodied vehicles, where the OEM floor has been

removed, each end of driveshaft must have round 360-degree driveshaft loops

within 6 inches of U-joints. Additionally, driveshaft must be covered by 360-

degree tube, covering the front U-joint and extending rearward a minimum 12

inches. Minimum thickness of tube is .050-inch chromoly or titanium. Driveshaft

tube must utilize a minimum of four attachment points to the chassis, either

bolted with minimum 5/16 SAE bolts or welded or 1/4-inch push/pull pins. See

General Regulations 2:4.

SECTION

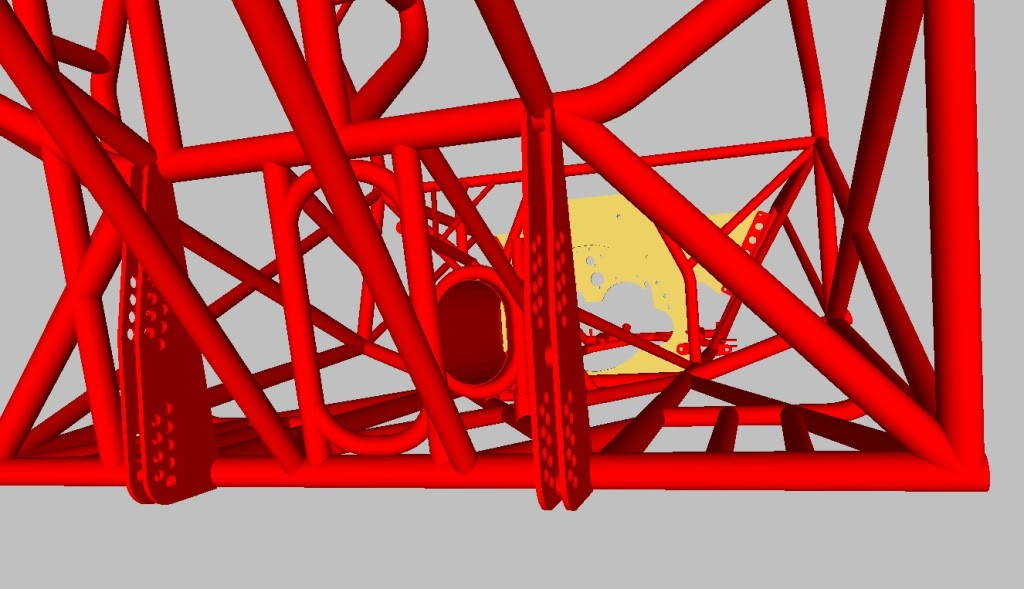

Thanks David, yep I knew about the rule change. I just haven't gotten around to adding all the little details. I forgot who's car this is, but this is basically what they're looking for.

Randy, it's the drawing perspective that makes it look like that. But going from memory it's somewhere around 75-80" from the back of the block to the axle center-line.KY JELLY wrote: How far is the back of the engine from the center of the axle that looks a tad far back from the drawing.

Re: The beginning of the next project.

Re: The beginning of the next project.

I guess whats making it look like that is the floor kick ups are angled back on the inboard sides of them. It looks really nice.

My engine plate is still probably 6" in front of my dash bar. The back of my engine is right at 78" from the center of the axle with a 110" wheel base.

If Blake and I are able to construct a nice mold of his 65 and the first body turns out good I have full intentions of trying a complete carbon fiber body for myself . I don't care if its got paint on it or not I don't feel right driving a shiny race car anyway

My engine plate is still probably 6" in front of my dash bar. The back of my engine is right at 78" from the center of the axle with a 110" wheel base.

If Blake and I are able to construct a nice mold of his 65 and the first body turns out good I have full intentions of trying a complete carbon fiber body for myself . I don't care if its got paint on it or not I don't feel right driving a shiny race car anyway

Last edited by KY JELLY on January 27th 2011, 1:01 pm; edited 1 time in total

KY JELLY- Posts : 1530

Join date : 2008-12-03

Re: The beginning of the next project.

Re: The beginning of the next project.

Looks great Doug! Here's a pic of my DS tube:

David Willingham- BBF CONTRIBUTOR

- Posts : 495

Join date : 2008-12-02

Age : 52

Location : Blountsville, AL

Re: The beginning of the next project.

Re: The beginning of the next project.

David Willingham wrote:Looks great Doug! Here's a pic of my DS tube:

That looks cool

Re: The beginning of the next project.

Re: The beginning of the next project.

KY JELLY wrote:If Blake and I are able to construct a nice mold of his 65 and the first body turns out good I have full intentions of trying a complete carbon fiber body for myself . I don't care if its got paint on it or not I don't feel right driving a shiny race car anyway

Keep me updated on that project Randy

Re: The beginning of the next project.

Re: The beginning of the next project.

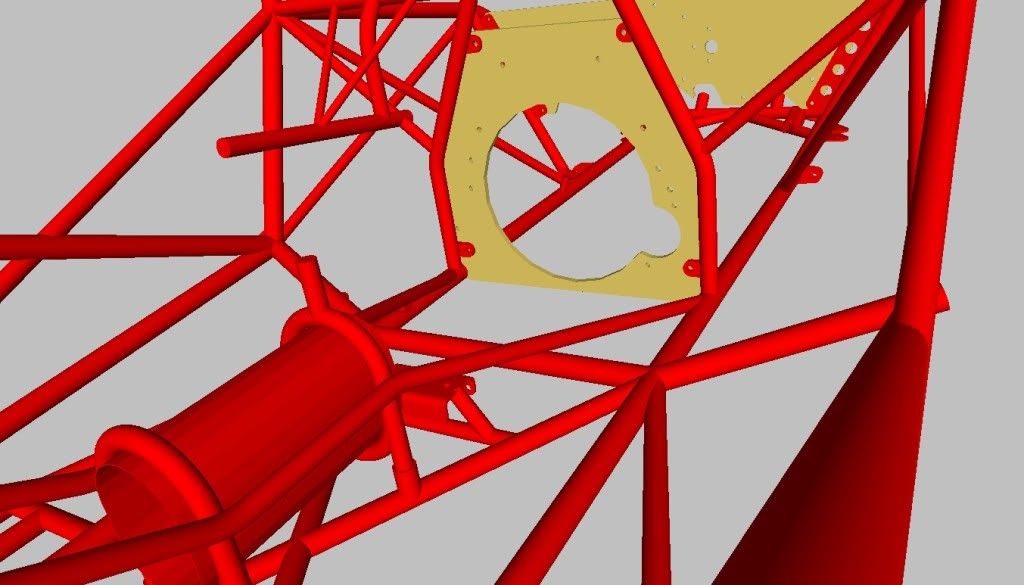

I updated the drawing with all the suggestions and some of my own. Right now I'm trying to get my hands on the material I need to build a nice chassis table. Good thing is this table will get used more than just once. My younger brother wants to build a Rock Crawler and as long as I'm still breathing this won't be my last car, knock on wood

Re: The beginning of the next project.

Re: The beginning of the next project.

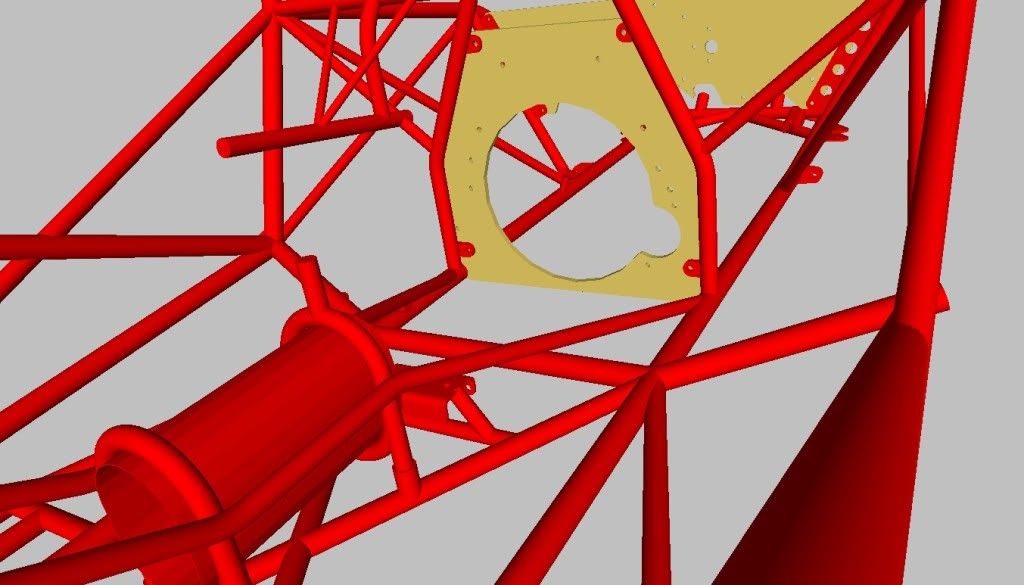

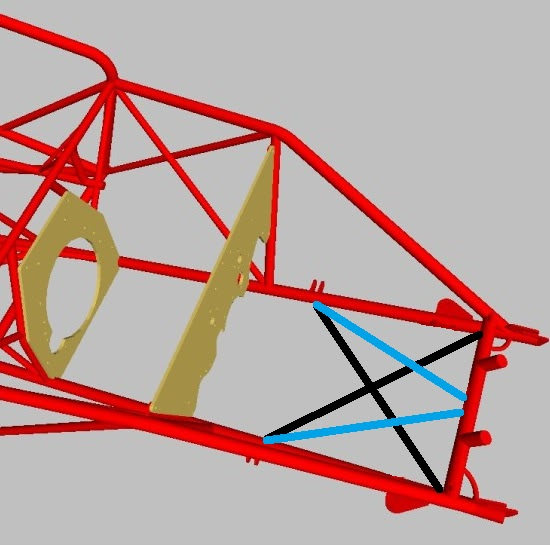

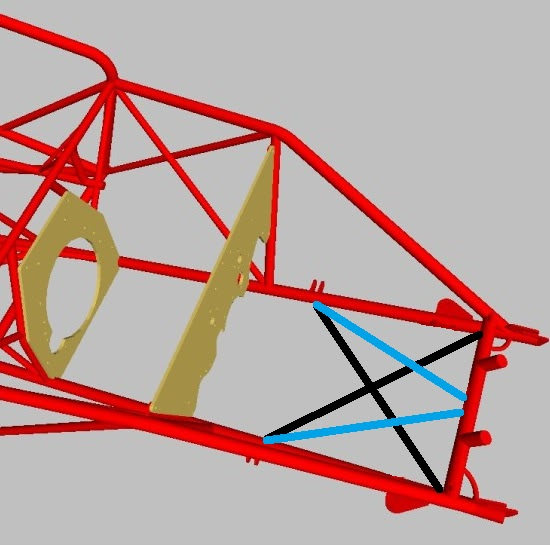

Looking at the pics again, some other possible options to think about.......

Since you raised/flattened the top of the motor plate, to save some weight you can also raise the bottom side too. Which line to follow depends on what might need to be hung/mounted off the bottom of the plate.

Some bracing could be added to help support the area where the back lower control arm mount and/or the motor plate upright attaches to the main frame rail. Usually it's two diagonals, (blue lines) but an "X" could be used instead as long as a center tow strap loop isn't used on the front crossmember. Also in the end your rack mounts might end up a little farther back. Depending on what strut is used the rack C/L might fall in the 8 - 10" range ahead of the front axle C/L with a normal width Pinto rack. If you end up needing the 5" narrower Pinto rack, that could change the final placement even more.

Dropping the center of the dash bar down a little to the top of the mid plate will add a little more "diagonal effect" helping transfer load from the plate to the outer cage bars. Plus it's a good way to seal the top of mid plate to rigid firewall surface without making the mid plate taller. The other small tube secondary firewall/floor diagonals I added were just because more diagonals is always more gooder.

You might also look at the possibility of making the diagonal double frame rail bars straight/straighter (instead of with multiple bends). Straight bars will be stronger/flex less under tension loading, but if the bend/bends have to be there to make room for the driver then there's not much you can do.

Since you raised/flattened the top of the motor plate, to save some weight you can also raise the bottom side too. Which line to follow depends on what might need to be hung/mounted off the bottom of the plate.

Some bracing could be added to help support the area where the back lower control arm mount and/or the motor plate upright attaches to the main frame rail. Usually it's two diagonals, (blue lines) but an "X" could be used instead as long as a center tow strap loop isn't used on the front crossmember. Also in the end your rack mounts might end up a little farther back. Depending on what strut is used the rack C/L might fall in the 8 - 10" range ahead of the front axle C/L with a normal width Pinto rack. If you end up needing the 5" narrower Pinto rack, that could change the final placement even more.

Dropping the center of the dash bar down a little to the top of the mid plate will add a little more "diagonal effect" helping transfer load from the plate to the outer cage bars. Plus it's a good way to seal the top of mid plate to rigid firewall surface without making the mid plate taller. The other small tube secondary firewall/floor diagonals I added were just because more diagonals is always more gooder.

You might also look at the possibility of making the diagonal double frame rail bars straight/straighter (instead of with multiple bends). Straight bars will be stronger/flex less under tension loading, but if the bend/bends have to be there to make room for the driver then there's not much you can do.

DILLIGASDAVE- Posts : 2262

Join date : 2009-08-08

Location : Texas. pronounced "texASS"

Re: The beginning of the next project.

Re: The beginning of the next project.

I think you could move those double frame bars out closer to the 4-link brackets. Mine are just inside the 4-link and are angled out to the bend in the trans crossmember and I have plenty of room at the seat, and I'm a pretty big guy. Not sure what the chassis width difference may be though.

BigDave65- Posts : 567

Join date : 2009-08-12

Age : 59

Location : Cliffside, NC

Page 1 of 2 • 1, 2

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum