P51 head repair

+2

dfree383

jc10000rpm

6 posters

Page 1 of 1

P51 head repair

P51 head repair

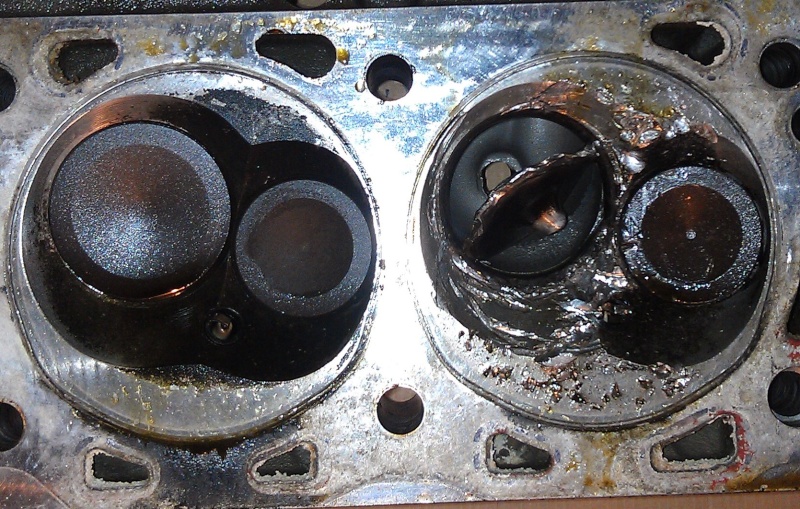

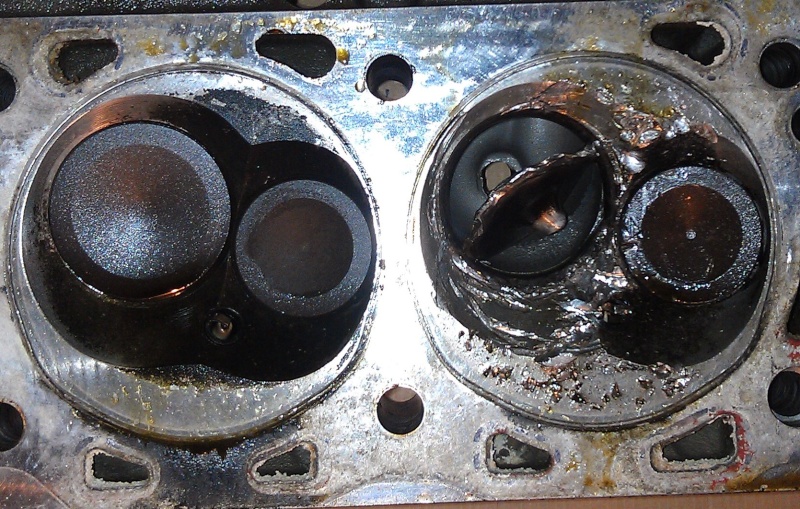

droped a intake valve at the end of last season and had charlie evans fix the head

The pictures speak for themselves, and he charged me too little maybe he will chime in and explain what all was involved.

maybe he will chime in and explain what all was involved.

Thanks for the good work, and to those who helped.

The pictures speak for themselves, and he charged me too little

Thanks for the good work, and to those who helped.

Last edited by jc10000rpm on September 5th 2012, 1:10 am; edited 1 time in total (Reason for editing : learn how to post pictures)

jc10000rpm- Posts : 193

Join date : 2008-12-03

Re: P51 head repair

Re: P51 head repair

Nice Job.

dfree383- BBF CONTRIBUTOR

- Posts : 14851

Join date : 2009-07-09

Location : Home Wif Da Wife.....

Re: P51 head repair

Re: P51 head repair

looks good , just curious is all that pitting going to cause issues down the road ?

_________________

coming soon x275 build .........

thanks to all my sponsors :

www.OakleyMotorsports.com

www.Induction-Solutions.com

www.bfevansraceparts.com

www.ultimateconverter.com

www.keithfulpmotorsports.com

Re: P51 head repair

Re: P51 head repair

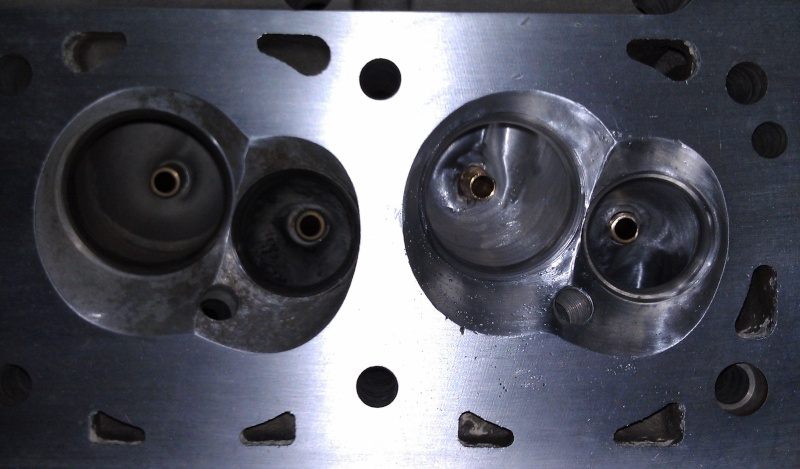

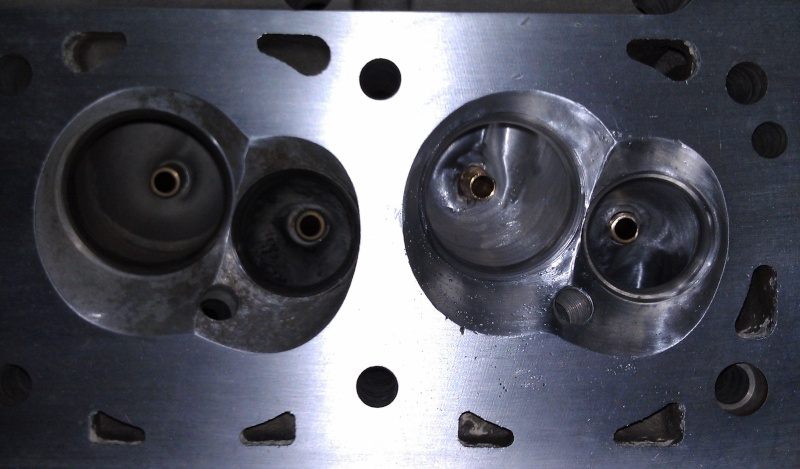

Thanks Jeff, I appreciate the kind words. In regards to what we had to do, as you can see, the intake guide was kocked out of it and the intake guide boss was also broken and the hole elongated. So we welded the intake guide boss up, and redrilled a new guide hole with the correct cant and incline angles. Also the entire chamber got welded twice and also the outlying areas of the deck surface got welded. Then new oversize guides and seats from C.H.E. out in California were pressed in after everything was machined correctly. C.H.E. is the original seat and guide supplier for the P-51 heads and the Boss Nine heads. The chamber was reshaped by hand and of course the head was milled.

Nick,

The little porosity holes are due to a couple of reasons, one being the quality of the original molten casting material, and one being contamination of the weld. In other words, many times the same welder can have a better looking weld on a different brand of head, and no it's not going to cause a problem. Those porosity holes are what a lot of 'youse' guys entire chambers look like,,,,,,when you miss on your nitrous tune-up

Uncle Charlie

Nick,

The little porosity holes are due to a couple of reasons, one being the quality of the original molten casting material, and one being contamination of the weld. In other words, many times the same welder can have a better looking weld on a different brand of head, and no it's not going to cause a problem. Those porosity holes are what a lot of 'youse' guys entire chambers look like,,,,,,when you miss on your nitrous tune-up

Uncle Charlie

c.evans- BBF VENDOR SPONSOR

- Posts : 2260

Join date : 2008-12-03

Re: P51 head repair

Re: P51 head repair

a little pepper on the plug is just right... a lot of pepper on the plug, not so good. Hot is fast, molten is expensive.

kim- Posts : 700

Join date : 2009-06-27

Location : Tucson AZ

Re: P51 head repair

Re: P51 head repair

Ouch. Charlies group does some nice work.

512Fairlane- Posts : 694

Join date : 2009-08-19

Location : Mid Missouri

Re: P51 head repair

Re: P51 head repair

my experience has been that carbon quickly fills in any <quote> imperfections, and the shape of that combustion chamber is dead on for the rest (iv seen it in person not just the pictures), i promise there are no issues with this repair job, i only hope i have enough time to get it back together soon.

thanks again

thanks again

jc10000rpm- Posts : 193

Join date : 2008-12-03

Similar topics

Similar topics» Head repair

» Head repair problem

» Aluminum cylinder head repair?

» D0OE repair.

» Carb work/repair needed

» Head repair problem

» Aluminum cylinder head repair?

» D0OE repair.

» Carb work/repair needed

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum