Dowel Pin Issue

4 posters

Page 1 of 1

Dowel Pin Issue

Dowel Pin Issue

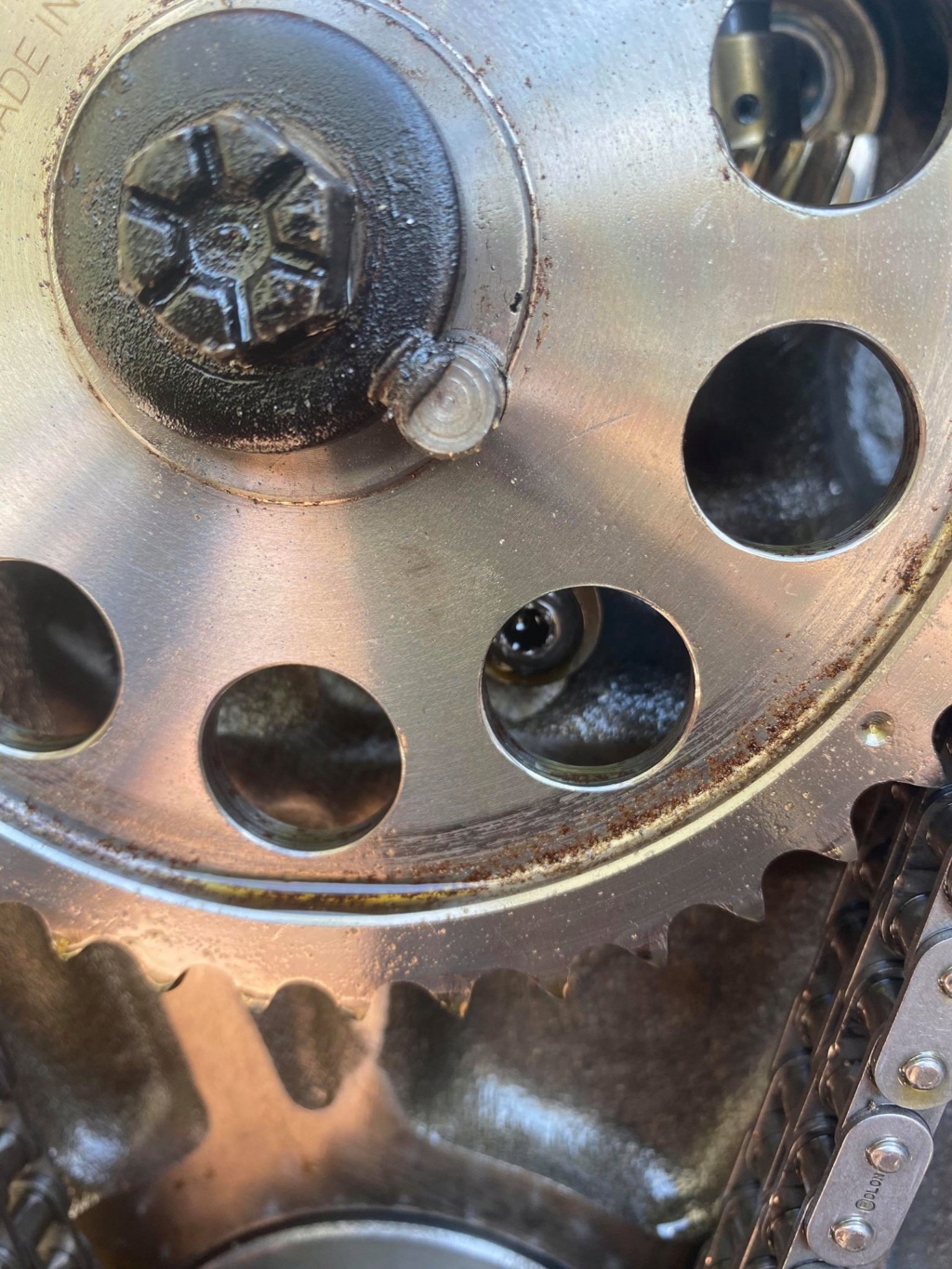

As you can see in the pic, we have a problem. First, let me say that this isn't my engine. It was built by a friend of mine, who isn't a Ford guy, for a friend of his. I believe it was in a big 4x4 mud truck. I believe it's a 598 Blue Thunder head engine, I'm guessing was making 8-900 hp. I know the bolt and washer set-up isn't ideal for this engine. I've made my buddy aware of that. I have not seen this engine in person, only offering help and advice through text messaging.

So, with that being said, the dowel isn't broken it just pushed past what little edge of the washer that covered it. The dowel came out enough that the gear slipped and valves hit pistons, breaking the head off of one of the exhaust. It is a Comp camshaft and it obviously damaged the outer portion of the hole. so he can't tell how loose or tight the pin fit in the hole. It seems to me the normal press fit on a dowel pin shouldn't have allowed this to happen, but I could be wrong.

I'm throwing this out to the group for any advice, theories, or similar experiences you have to offer. Thanks in advance for any help!

BigDave65- Posts : 567

Join date : 2009-08-12

Age : 59

Location : Cliffside, NC

Re: Dowel Pin Issue

Re: Dowel Pin Issue

BigDave65 wrote:

As you can see in the pic, we have a problem. First, let me say that this isn't my engine. It was built by a friend of mine, who isn't a Ford guy, for a friend of his. I believe it was in a big 4x4 mud truck. I believe it's a 598 Blue Thunder head engine, I'm guessing was making 8-900 hp. I know the bolt and washer set-up isn't ideal for this engine. I've made my buddy aware of that. I have not seen this engine in person, only offering help and advice through text messaging.

So, with that being said, the dowel isn't broken it just pushed past what little edge of the washer that covered it. The dowel came out enough that the gear slipped and valves hit pistons, breaking the head off of one of the exhaust. It is a Comp camshaft and it obviously damaged the outer portion of the hole. so he can't tell how loose or tight the pin fit in the hole. It seems to me the normal press fit on a dowel pin shouldn't have allowed this to happen, but I could be wrong.

I'm throwing this out to the group for any advice, theories, or similar experiences you have to offer. Thanks in advance for any help!

The long length dowel pin is to be used to drive a one piece fuel pump eccentric; with no eccentric, using a shorter dowel pin requires a washer large enough to cover it.

Re: Dowel Pin Issue

Re: Dowel Pin Issue

Thanks Randy. To be honest, I've never messed with any stock BBF builds, only race engines. I didn't know about a longer dowel pin. I'm sure he will get it straightened out, it just cost him a few extra bucks to learn the lesson.

BigDave65- Posts : 567

Join date : 2009-08-12

Age : 59

Location : Cliffside, NC

Re: Dowel Pin Issue

Re: Dowel Pin Issue

BigDave65 wrote:it just cost him a few extra bucks to learn the lesson.

Cubic dollars will fix most problems.

Curt- Posts : 2791

Join date : 2009-02-08

Age : 62

Location : Henrietta, Texas but mostly on the road

Re: Dowel Pin Issue

Re: Dowel Pin Issue

Curt wrote:BigDave65 wrote:it just cost him a few extra bucks to learn the lesson.

Cubic dollars will fix most problems.

Not at all, just common sense.

Gary Blair- Posts : 221

Join date : 2009-10-28

Similar topics

Similar topics» A460 main cap pins - what are they for, locating, cap walk, ?

» cam dowel

» Dowel Pins

» Sheared Cam Dowel on SBF...

» New Cam Dual Dowel Pins?

» cam dowel

» Dowel Pins

» Sheared Cam Dowel on SBF...

» New Cam Dual Dowel Pins?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum