Quick and Dirty Rebuild of the 565 - Thanks Lem

+5

J.Toney

Paul Kane

Lem Evans

norm

G-Code

9 posters

Page 1 of 2

Page 1 of 2 • 1, 2

Quick and Dirty Rebuild of the 565 - Thanks Lem

Quick and Dirty Rebuild of the 565 - Thanks Lem

Hey Lem - Thanks for the parts sourcing - Rings, head gaskets, intake gaskets, new belt for the Danny Bee.

I wish I had known we were going to replace the cam bearings and I would have got your special recipe of Akerly and Childs bearings for this "quick" rebuild. I'll get a set for Next time ...

Anyway it's coming together ..... We'll work on it a few hours tomorrow and the heads will be on before the sun goes down.

For the engine being put together in 2011 and having many hours of run time on it and 100's of miles on the river the rod bearings are looking pretty good.

5 rods looked like this:

the other 3 looked like this:

The mains were about the same condition.

Got the Danny Bee installed (I got this from you about 8 years ago and had it on the 840 hp 528" pump gas engine)

We got the cam degreed and the pistons in this evening. We'll be back at it tomorrow.

Trying something different with this cam. We'll see how it works out in the next couple of weeks.

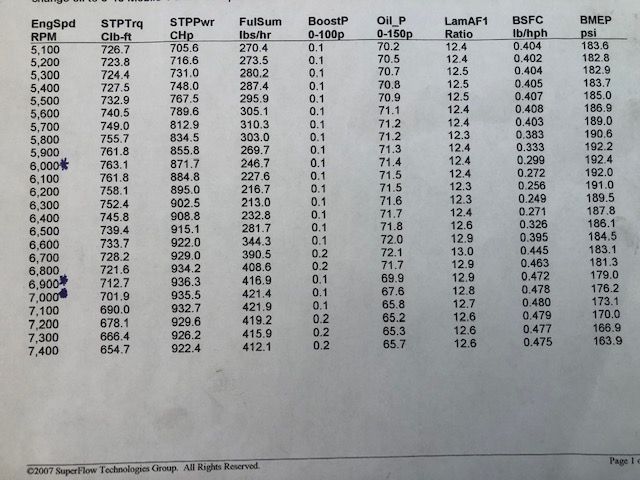

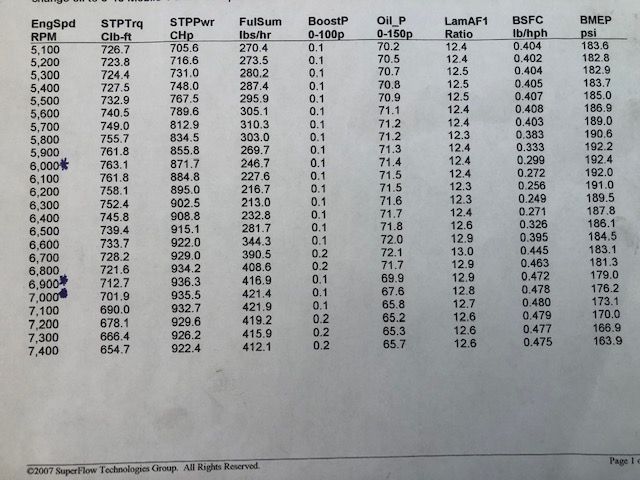

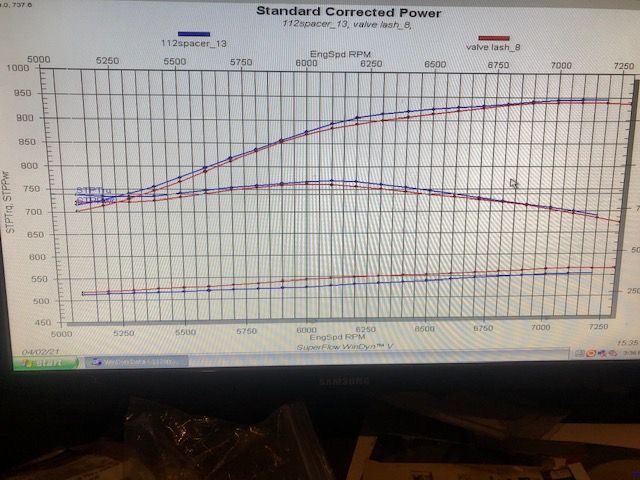

Dyno sheet from 2011. Single 1,050, 13:1, C12

_dynomaxpower.jpg?width=1920&height=1080&fit=bounds)

We're shooting for a bit more on this rebuild... I'll keep you posted.

PS:

While the engine has been apart this winter the rockers got shipped off to T&D for an inspection and they rebuilt them with new roller bearings and replaced two set screws for a total of $74.00 ( money well spent) and the Crower Hippo lifters were rebuilt down at Crower for a bit more than that. I dropped them off on a Tuesday and they called me on Thursday afternoon and said they were done. About $325 for the rebuild.

I wish I had known we were going to replace the cam bearings and I would have got your special recipe of Akerly and Childs bearings for this "quick" rebuild. I'll get a set for Next time ...

Anyway it's coming together ..... We'll work on it a few hours tomorrow and the heads will be on before the sun goes down.

For the engine being put together in 2011 and having many hours of run time on it and 100's of miles on the river the rod bearings are looking pretty good.

5 rods looked like this:

the other 3 looked like this:

The mains were about the same condition.

Got the Danny Bee installed (I got this from you about 8 years ago and had it on the 840 hp 528" pump gas engine)

We got the cam degreed and the pistons in this evening. We'll be back at it tomorrow.

Trying something different with this cam. We'll see how it works out in the next couple of weeks.

Dyno sheet from 2011. Single 1,050, 13:1, C12

_dynomaxpower.jpg?width=1920&height=1080&fit=bounds)

We're shooting for a bit more on this rebuild... I'll keep you posted.

PS:

While the engine has been apart this winter the rockers got shipped off to T&D for an inspection and they rebuilt them with new roller bearings and replaced two set screws for a total of $74.00 ( money well spent) and the Crower Hippo lifters were rebuilt down at Crower for a bit more than that. I dropped them off on a Tuesday and they called me on Thursday afternoon and said they were done. About $325 for the rebuild.

Last edited by G-Code on March 21st 2021, 12:46 pm; edited 2 times in total

G-Code- Posts : 193

Join date : 2010-07-12

jasonf and Mark Miller like this post

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Bearings look awesome for that amount of time.

How much oil pressure did it have? Idle and under load?

Cam bearings worn on the bottom?

How much oil pressure did it have? Idle and under load?

Cam bearings worn on the bottom?

norm- Posts : 261

Join date : 2009-08-06

Location : michigan

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

That dyno sheet was running the Kaase pump. I had some psi issues in the boat with the oil cooler and external filter system. I worked with Paul Kane (Hi Paul) on the pan, pump and pick up. I sent Paul the pan and He came up with a good system with one of his blue printed pumps and custom built pick ups. Idle psi typically 30 and runs in the mid 60's with 200* oil temp for 15-20 mile runs on the river. WOT on the nitrous at 7,000 rpm it runs 58 psi. Oil is always Mobil 1 20/50.

Yes, cam bearings worn where the load is.

These are the two filter systems it's been running over the past 10 years. The single Cummings filter has been on for the past 4, but I'm thinking about switching back to the duals this summer.

_5652013_zpsdfd6c271.jpg?width=1920&height=1080&fit=bounds)

The Cummings filter flows 24 gpm at 10 psi with a 12 micron filter at 85% efficiency (no bypass) . I have it plumbed with -12's

The Baldwin racing B253 flows 12 gpm at 5 psi with a 18 micron filter at 74% efficiency (has bypass). I have it plumed with -10's

For reference... The Wix Racing filter people use flows approx 20 gpm if I recall) but has a 61 micron filter medium. Not the best of choices for an engine that will be together for a long time. IMO

Yes, cam bearings worn where the load is.

These are the two filter systems it's been running over the past 10 years. The single Cummings filter has been on for the past 4, but I'm thinking about switching back to the duals this summer.

_5652013_zpsdfd6c271.jpg?width=1920&height=1080&fit=bounds)

The Cummings filter flows 24 gpm at 10 psi with a 12 micron filter at 85% efficiency (no bypass) . I have it plumbed with -12's

The Baldwin racing B253 flows 12 gpm at 5 psi with a 18 micron filter at 74% efficiency (has bypass). I have it plumed with -10's

For reference... The Wix Racing filter people use flows approx 20 gpm if I recall) but has a 61 micron filter medium. Not the best of choices for an engine that will be together for a long time. IMO

Last edited by G-Code on March 21st 2021, 2:44 pm; edited 5 times in total

G-Code- Posts : 193

Join date : 2010-07-12

G-Code likes this post

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Regarding the cam bearings and load:

The heads went together (in 2011) with a set of PSI Super Clean Silicone springs (dual spring) I think it's the spring Crower sold as PN: 68755.

When they were assembled in 2011 they went together at 300 on the seat at 2.115" & 725 @ 1.344"

Yesterday they were checked at 295 and 715. (The weakest of them)

The cam was just .434" lobe lift with a 1.8 rocker.

I haven't backed those springs off for the past several years and didn't even spin the engine over during winter for the past 3. They're going back on the heads today.

G-Code- Posts : 193

Join date : 2010-07-12

Mark Miller likes this post

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

G-Code wrote:...I worked with Paul Kane (Hi Paul) on the pan, pump and pick up. I sent Paul the pan and He came up with a good system with one of his...pumps and custom built pick ups. Idle psi typically 30 and runs in the mid 60's with 200* oil temp for 15-20 mile runs on the river. WOT on the nitrous at 7,000 rpm it runs 58 psi. Oil is always Mobil 1 20/50....

G-Code and nascar429 like this post

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Bigger tube is the way to go!

Paul Kane likes this post

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Good stuff!!

More info on the build? Bore/stroke?

More info on the build? Bore/stroke?

J.Toney- Posts : 398

Join date : 2009-08-18

Location : Kent CIty, MI

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Here's a link to the thread on the build from 2011:

https://www.429-460.com/t11605-940-hp-565-a-460-finally

G-Code- Posts : 193

Join date : 2010-07-12

J.Toney likes this post

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Lem Evans wrote:Bigger tube is the way to go!

That's what she said!

Curt- Posts : 2791

Join date : 2009-02-08

Age : 62

Location : Henrietta, Texas but mostly on the road

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Spending a couple of days in one of my most favorite places on earth .......

Up dates to come....

That's a little electric vac pump you see hanging off the back of the engine.

Static vac 4" ...

Running with engine at 7,000 1.5" vac

Steve was sure the vac pump would not keep up with the 565" at rpm. He said that he had seem sm blks over load them,

We were dropping a quart of oil out of the engine and the vac pump was still on. Steve puled the drain plug and not a drop of oil came out of the pan. We turned off the switch and the oil flowed.

Up dates to come....

That's a little electric vac pump you see hanging off the back of the engine.

Static vac 4" ...

Running with engine at 7,000 1.5" vac

Steve was sure the vac pump would not keep up with the 565" at rpm. He said that he had seem sm blks over load them,

We were dropping a quart of oil out of the engine and the vac pump was still on. Steve puled the drain plug and not a drop of oil came out of the pan. We turned off the switch and the oil flowed.

G-Code- Posts : 193

Join date : 2010-07-12

J.Toney and Mark Miller like this post

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Looking forward to your detailed updates!!

J.Toney- Posts : 398

Join date : 2009-08-18

Location : Kent CIty, MI

Mark Miller likes this post

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

...

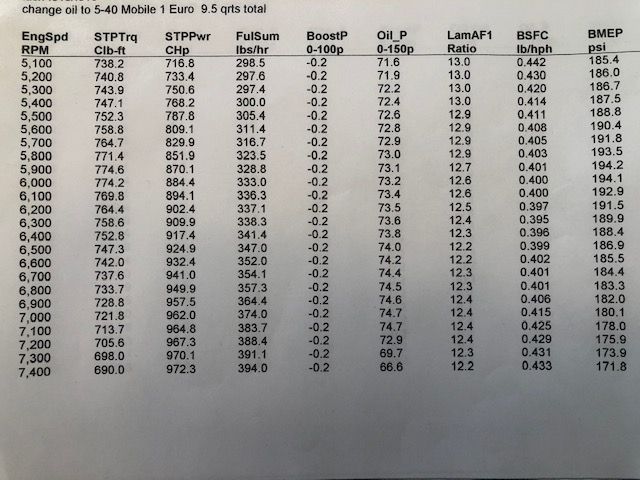

I'll post some numbers tomorrow:

I'll post some numbers tomorrow:

Last edited by G-Code on March 27th 2021, 2:34 am; edited 2 times in total (Reason for editing : update)

G-Code- Posts : 193

Join date : 2010-07-12

nascar429 likes this post

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

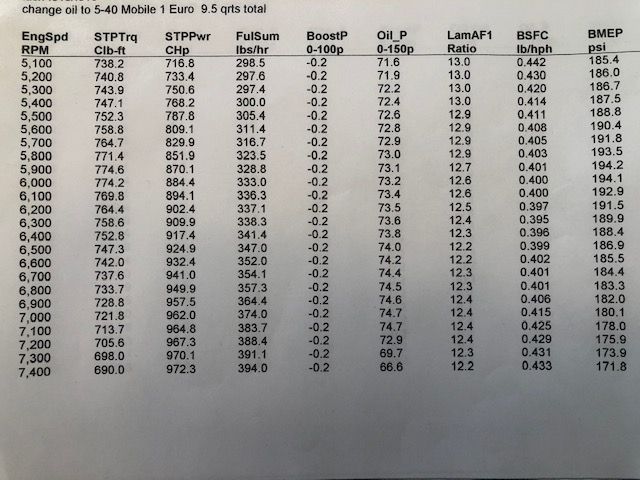

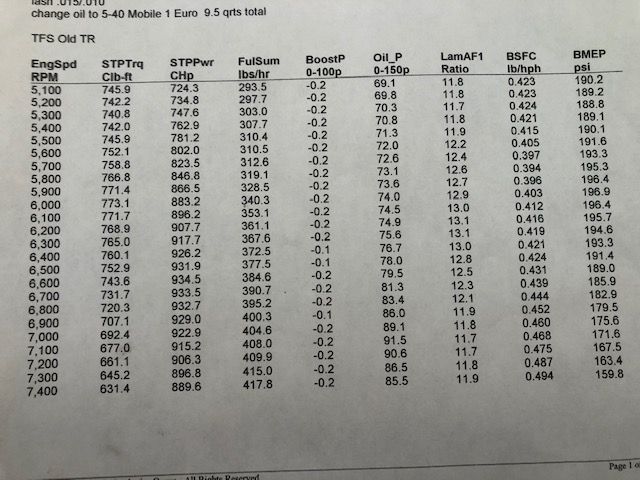

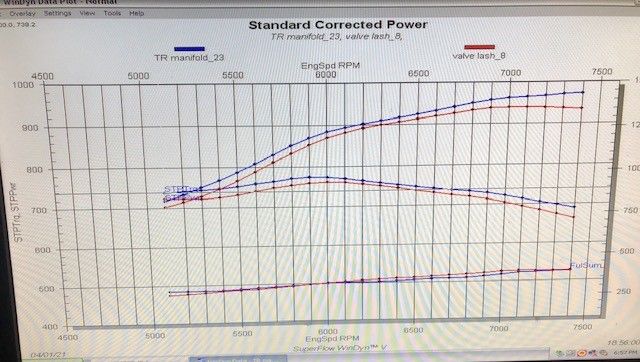

Single 1,200.

Electric Vac pump pulling 1.8" ( left of oil psi)

.jpg?width=1920&height=1080&fit=bounds)

HP & Trq numbers: We never tried to "Print a number" with the single 4. I doubt the oil temp ever got over 160*. So there's more in that combination. We just didn't Chase it.

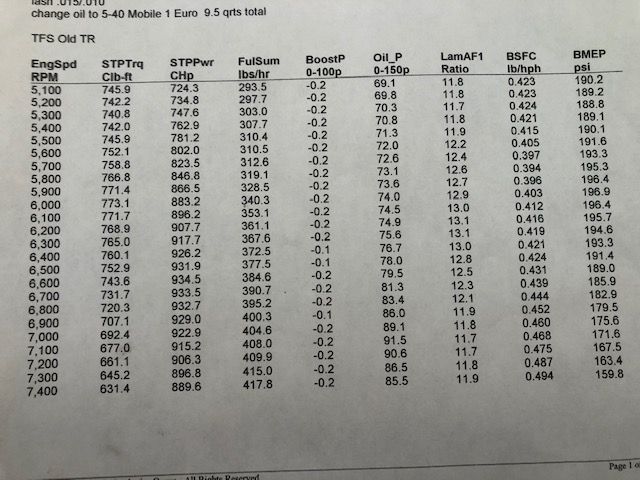

tunnel ram - dual 1,050's

the engine is running the Kaase oil pump with Paul Kane's big tube pickup.

Learned a few things .... might go back in 6 weeks ...... might

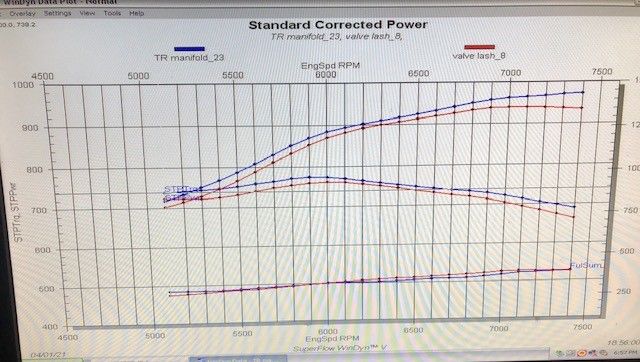

The Old "Holmes" TR generated a water leak some how and we only got a single pull out of it. I'll say there is more power to be gained from what we saw, but the power peaks will be the same: peak power 6,600 and peak trq at 6,000

Electric Vac pump pulling 1.8" ( left of oil psi)

.jpg?width=1920&height=1080&fit=bounds)

HP & Trq numbers: We never tried to "Print a number" with the single 4. I doubt the oil temp ever got over 160*. So there's more in that combination. We just didn't Chase it.

tunnel ram - dual 1,050's

the engine is running the Kaase oil pump with Paul Kane's big tube pickup.

Learned a few things .... might go back in 6 weeks ...... might

The Old "Holmes" TR generated a water leak some how and we only got a single pull out of it. I'll say there is more power to be gained from what we saw, but the power peaks will be the same: peak power 6,600 and peak trq at 6,000

G-Code- Posts : 193

Join date : 2010-07-12

hbstang likes this post

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

A little video of the first run over 970:

.MOV?width=1920&height=1080&fit=bounds)

Click image for video link.

On the third pull with the tunnel ram the intake blew out the silicone on the rear China wall. We turned on the vac pump to keep the engine sealed. It was running on the TR showing -.5". At the end of this run the crankcase goes positive by .5". It's the second reading over on the lower left.

We'll be working on fitting the new GZ pump over the next couple of weeks. There's some power there with running 9" -12" in the future.

.MOV?width=1920&height=1080&fit=bounds)

Click image for video link.

On the third pull with the tunnel ram the intake blew out the silicone on the rear China wall. We turned on the vac pump to keep the engine sealed. It was running on the TR showing -.5". At the end of this run the crankcase goes positive by .5". It's the second reading over on the lower left.

We'll be working on fitting the new GZ pump over the next couple of weeks. There's some power there with running 9" -12" in the future.

G-Code- Posts : 193

Join date : 2010-07-12

J.Toney and nascar429 like this post

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Here's another video link for those who don't have Photobucket

https://vimeo.com/530160429

It sounds like it wants another 500 rpm.

https://vimeo.com/530160429

It sounds like it wants another 500 rpm.

G-Code- Posts : 193

Join date : 2010-07-12

J.Toney likes this post

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

So the Holmes Ram peaked similar on tq but pretty early compared to the later version TR if I'm reading right.

J.Toney- Posts : 398

Join date : 2009-08-18

Location : Kent CIty, MI

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

G-Code wrote:

The Old "Holmes" TR generated a water leak some how and we only got a single pull out of it. I'll say there is more power to be gained from what we saw, but the power peaks will be the same: peak power 6,600 and peak trq at 6,000

Got a chance to look at the engine yesterday and drain the oil.

There was enough water in the oil that the volume of water had to be killing the power. It would have been like having 3 extra qrts of oil in the pan ( if not more). The Holmes has much more in it than shows on that run.

The Holmes intake has some potential, but I won't be testing it again this year. Maybe down the road on a different build, but I need to figure out how the water got pass the gaskets. Things kind of looked ok when I pulled it apart. We're going to pressure test the heads/block sometime this week. The heads bolts were all still pretty close to 135 lbs.

It will be going back together with the "new" TR with some work done on it and headed back to the dyno down the road, unless we find something really screwed up with it.

G-Code- Posts : 193

Join date : 2010-07-12

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

What's next ....

testing for the leak. We didn't find the water leak at the manifold and gasket seal (at least not yet), so I'm pressure testing the heads to see if there's a leak there or at a head gasket. I should have that figured out by tonight.

If I don't find a leak in the heads or a cly we'll bolt the new TR back on (after some internal mods) and go do some testing in May.

They're will be a new addition to the setup when we go:

G-Code- Posts : 193

Join date : 2010-07-12

nascar429 likes this post

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Great work! thanks for posting a thorough break down of the different setups a tough combo..i think the vacuum pump and tunnel ram mods may well get you those 4 digits that most everybody likes to see good luck!

nascar429- Posts : 91

Join date : 2015-11-08

G-Code likes this post

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

^ Thanks... I'll update a few things before the next dyno day. It's a ways out.

This experience has me wanting to design my own tunnel ram ........

This experience has me wanting to design my own tunnel ram ........

G-Code- Posts : 193

Join date : 2010-07-12

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

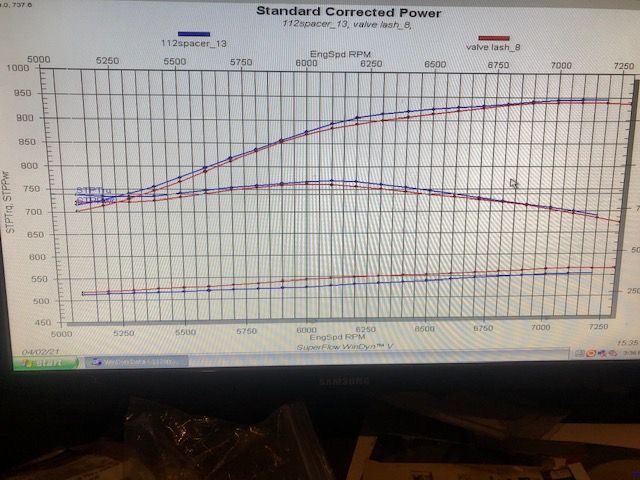

Comparison of the 2011 fresh build vs this "quick and dirty" rebuild of 2021:

2011 cam specs ( Blue) EDIT ON THE CAM Specs: The cam lost a roller lifter in 2009 and Crower reground the cam with a new spec. The cam that was run on the dyno in 2011 and in the engine for the past 10 years was a big different: These are the specs off the cam doctor when we checked it in December:

278/285 @ .050 lobe lift .433 /.435, 281/286 @.050 .435/.438, 1.8 rocker, 113 lobe sep (installed at 4* advanced intake opening at 30*) 109IC ( Seat to seat 312/317 dur at .200 - 201/205 )

2021 cam specs ( Red)

275/276 @ .050 lobe lift .455/.421, 1.8 rocker, 113 lobe sep installed straight up. intake opening at 23*

( Seat to seat 306/314 dur at .200 - 196/185 )

There is more than one way to skin a cat: Edit on correct graph

TR vs Single 4: 2021

2011 cam specs ( Blue) EDIT ON THE CAM Specs: The cam lost a roller lifter in 2009 and Crower reground the cam with a new spec. The cam that was run on the dyno in 2011 and in the engine for the past 10 years was a big different: These are the specs off the cam doctor when we checked it in December:

2021 cam specs ( Red)

275/276 @ .050 lobe lift .455/.421, 1.8 rocker, 113 lobe sep installed straight up. intake opening at 23*

( Seat to seat 306/314 dur at .200 - 196/185 )

There is more than one way to skin a cat: Edit on correct graph

TR vs Single 4: 2021

Last edited by G-Code on April 3rd 2021, 1:35 pm; edited 1 time in total

G-Code- Posts : 193

Join date : 2010-07-12

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Curiosity- is it a boat thing to have the intake and exhaust duration so close?

Generally see alot more split

Generally see alot more split

norm- Posts : 261

Join date : 2009-08-06

Location : michigan

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

norm wrote:Curiosity- is it a boat thing to have the intake and exhaust duration so close?

Generally see alot more split

Not necessarily, but on this engine the exhaust flow numbers are pushing 80% of intake flow. This time around it's not going to see a big shot of nitrous ( if even at all) so this combination doesn't demand a big split on the duration. At least that's our theory anyway.

G-Code- Posts : 193

Join date : 2010-07-12

Mark Miller likes this post

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

Re: Quick and Dirty Rebuild of the 565 - Thanks Lem

I meant to ask this ... ... Spark Plugs

I've run the Autolite 51's for years and was having a hard time locating them locally a few days before dyno day. My local Ford connection told me to switch over to the NGK R5671A-9. So that's what we ran on the dyno.

I'm think for running in the boat and all the recreation running it does I might go to the -8 plug.

G-Code- Posts : 193

Join date : 2010-07-12

Page 1 of 2 • 1, 2

Similar topics

Similar topics» so im gutting my little 302 for a quick shortblock rebuild.....

» 60' time - how quick is too quick for mech. fuel pump?

» getting dirty

» Got my hands dirty today....

» Finally got the truck dirty

» 60' time - how quick is too quick for mech. fuel pump?

» getting dirty

» Got my hands dirty today....

» Finally got the truck dirty

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum