valve to cylinder bore/block clearance

5 posters

Page 1 of 1

valve to cylinder bore/block clearance

valve to cylinder bore/block clearance

just wondering what the minimum exhaust valve to bore/ block clearance can be and safely not have interferance issues.?

reason being i have a sr-71 on a 4.39 bore and had exhaust valve collision . so long story short i "eyebrowed " the tops of the bores i got ok clearance but i can only come down the bore .200 from deck as my top ring runs too .270 and i do not want to get too close to that area. i have .026 clearance now . my only other option i think is grind the valves too a smaller diameter . .

what you guys think thanks

reason being i have a sr-71 on a 4.39 bore and had exhaust valve collision . so long story short i "eyebrowed " the tops of the bores i got ok clearance but i can only come down the bore .200 from deck as my top ring runs too .270 and i do not want to get too close to that area. i have .026 clearance now . my only other option i think is grind the valves too a smaller diameter . .

what you guys think thanks

maverick172- Posts : 205

Join date : 2022-10-16

Re: valve to cylinder bore/block clearance

Re: valve to cylinder bore/block clearance

Boss 302's have eyebrows in the block for valve clearance by design. You could research that clearance geometry to see how it compares to your mods. Tim Meyer AKA Drag Boss on YouTube may be of assistance

Dave De- Posts : 797

Join date : 2011-05-27

Location : Highland, MI

Re: valve to cylinder bore/block clearance

Re: valve to cylinder bore/block clearance

My thought about it is that it is going to be very hard to Measure Accurately without a Gauge Valve or two, Do to it's Radial Nature and guide play, as well as Maintaining that Clearance all the WAY were it passes the Block Deck Surface.

Not gung ho on cutting the Valves on $3,000 heads that likely where bought for there flow Potential and HP, at all!

Not gung ho on cutting the Valves on $3,000 heads that likely where bought for there flow Potential and HP, at all!

supervel45- Posts : 4499

Join date : 2013-09-04

maverick172 likes this post

Re: valve to cylinder bore/block clearance

Re: valve to cylinder bore/block clearance

maverick172 wrote:just wondering what the minimum exhaust valve to bore/ block clearance can be and safely not have interferance issues.?

reason being i have a sr-71 on a 4.39 bore and had exhaust valve collision . so long story short i "eyebrowed " the tops of the bores i got ok clearance but i can only come down the bore .200 from deck as my top ring runs too .270 and i do not want to get too close to that area. i have .026 clearance now . my only other option i think is grind the valves too a smaller diameter . .

what you guys think thanks

AS the valve opens, because of the side-cant angle, it will never get closer to the bore if the vertical height in the chamber from the block deck remains the same. Worn out guides is the only way.

On big block Chevy eyebrows, I always shoot for .030" clearance ... you are about there.

QtrWarrior and maverick172 like this post

Re: valve to cylinder bore/block clearance

Re: valve to cylinder bore/block clearance

Maybe a 1.76" valve as a go/no go gauge.

maverick172 likes this post

Re: valve to cylinder bore/block clearance

Re: valve to cylinder bore/block clearance

Lem Evans wrote:Maybe a 1.76" valve as a go/no go gauge.

That is what I meant. You can whiggle it back and forth while turning it, and see/feel if it contacts.

supervel45- Posts : 4499

Join date : 2013-09-04

Lem Evans likes this post

Re: valve to cylinder bore/block clearance

Re: valve to cylinder bore/block clearance

well i cannot go any more on the "eyebrowing" i am like .020 away from were the ring rids in the bore and the tightest bore i have .024 so i may have to grind the valves.rmcomprandy wrote:maverick172 wrote:just wondering what the minimum exhaust valve to bore/ block clearance can be and safely not have interferance issues.?

reason being i have a sr-71 on a 4.39 bore and had exhaust valve collision . so long story short i "eyebrowed " the tops of the bores i got ok clearance but i can only come down the bore .200 from deck as my top ring runs too .270 and i do not want to get too close to that area. i have .026 clearance now . my only other option i think is grind the valves too a smaller diameter . .

what you guys think thanks

AS the valve opens, because of the side-cant angle, it will never get closer to the bore if the vertical height in the chamber from the block deck remains the same. Worn out guides is the only way.

On big block Chevy eyebrows, I always shoot for .030" clearance ... you are about there.

i tried 2 head gaskets so i have .082 clearnace and it only gave me like .002 of extra clearance so thicker head gaskets does not real give any room

maverick172- Posts : 205

Join date : 2022-10-16

Re: valve to cylinder bore/block clearance

Re: valve to cylinder bore/block clearance

How are you checking the angle?

It might me best to put it away for the weekend, until you can talk to Kaase.

Like I said, don't rule out the offset dowl pins just yet. The valve angle and edge and all that help flow as well as heat on exhaust valves.

Did you check those plugs in the front of the block for depth, like Dave said?

It might me best to put it away for the weekend, until you can talk to Kaase.

Like I said, don't rule out the offset dowl pins just yet. The valve angle and edge and all that help flow as well as heat on exhaust valves.

Did you check those plugs in the front of the block for depth, like Dave said?

supervel45- Posts : 4499

Join date : 2013-09-04

Re: valve to cylinder bore/block clearance

Re: valve to cylinder bore/block clearance

well for angle i "eyebrowed out to the 4.5 bore so it is from that size down to the .250 into the hole is my 2 perameters i went off,

only problem with offset dowels is i would have to drill all my holes for my head bolts ..

yes i checked the plugs and it is not blocking the crosser port and they are the tapered 3/8 plugs in the front 2 holes ./

only problem with offset dowels is i would have to drill all my holes for my head bolts ..

yes i checked the plugs and it is not blocking the crosser port and they are the tapered 3/8 plugs in the front 2 holes ./

supervel45 wrote:How are you checking the angle?

It might me best to put it away for the weekend, until you can talk to Kaase.

Like I said, don't rule out the offset dowl pins just yet. The valve angle and edge and all that help flow as well as heat on exhaust valves.

Did you check those plugs in the front of the block for depth, like Dave said?

maverick172- Posts : 205

Join date : 2022-10-16

Re: valve to cylinder bore/block clearance

Re: valve to cylinder bore/block clearance

maverick172 wrote:well for angle i "eyebrowed out to the 4.5 bore so it is from that size down to the .250 into the hole is my 2 perameters i went off,

only problem with offset dowels is i would have to drill all my holes for my head bolts ..

yes i checked the plugs and it is not blocking the crosser port and they are the tapered 3/8 plugs in the front 2 holes ./supervel45 wrote:How are you checking the angle?

It might me best to put it away for the weekend, until you can talk to Kaase.

Like I said, don't rule out the offset dowl pins just yet. The valve angle and edge and all that help flow as well as heat on exhaust valves.

Did you check those plugs in the front of the block for depth, like Dave said?

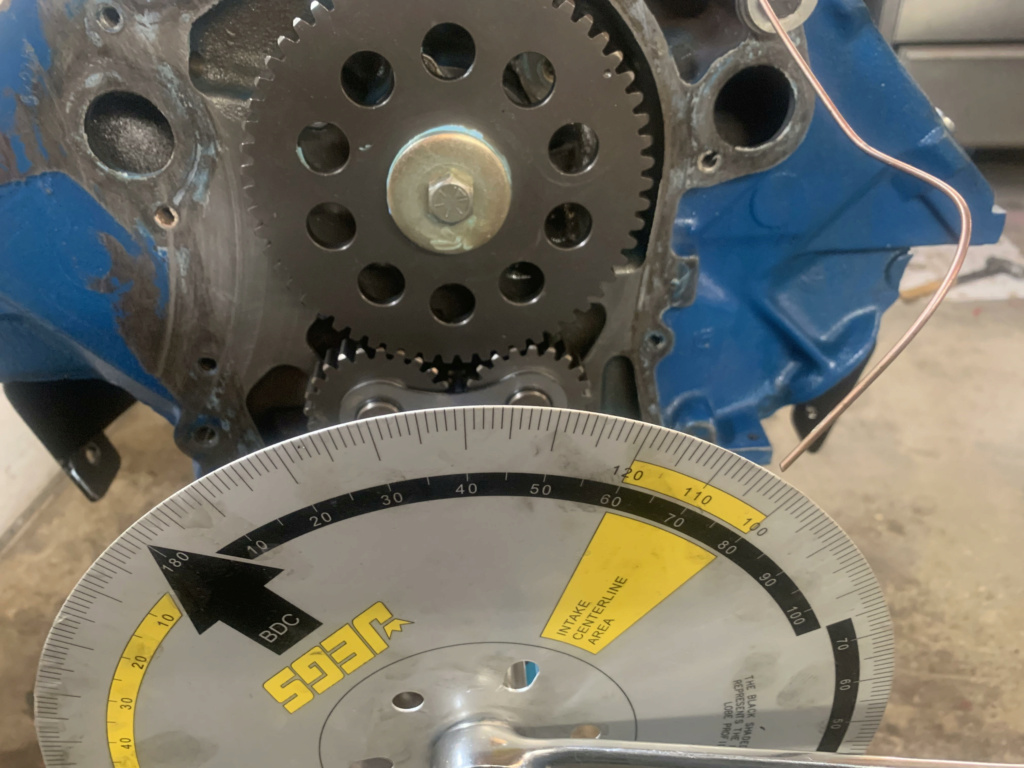

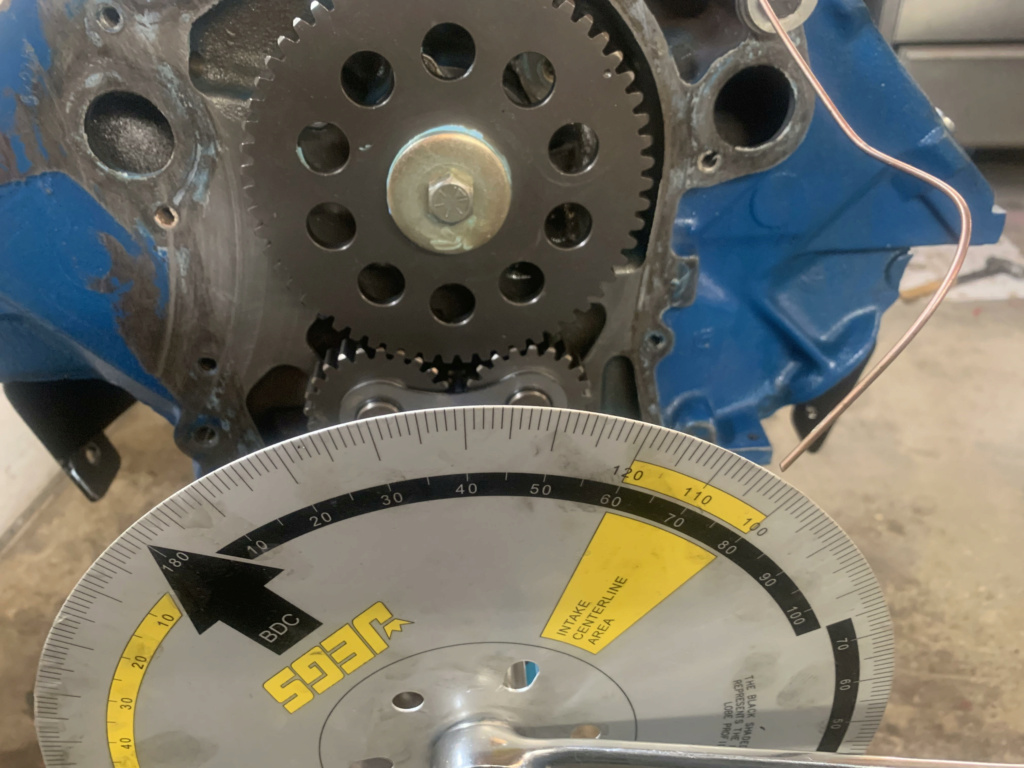

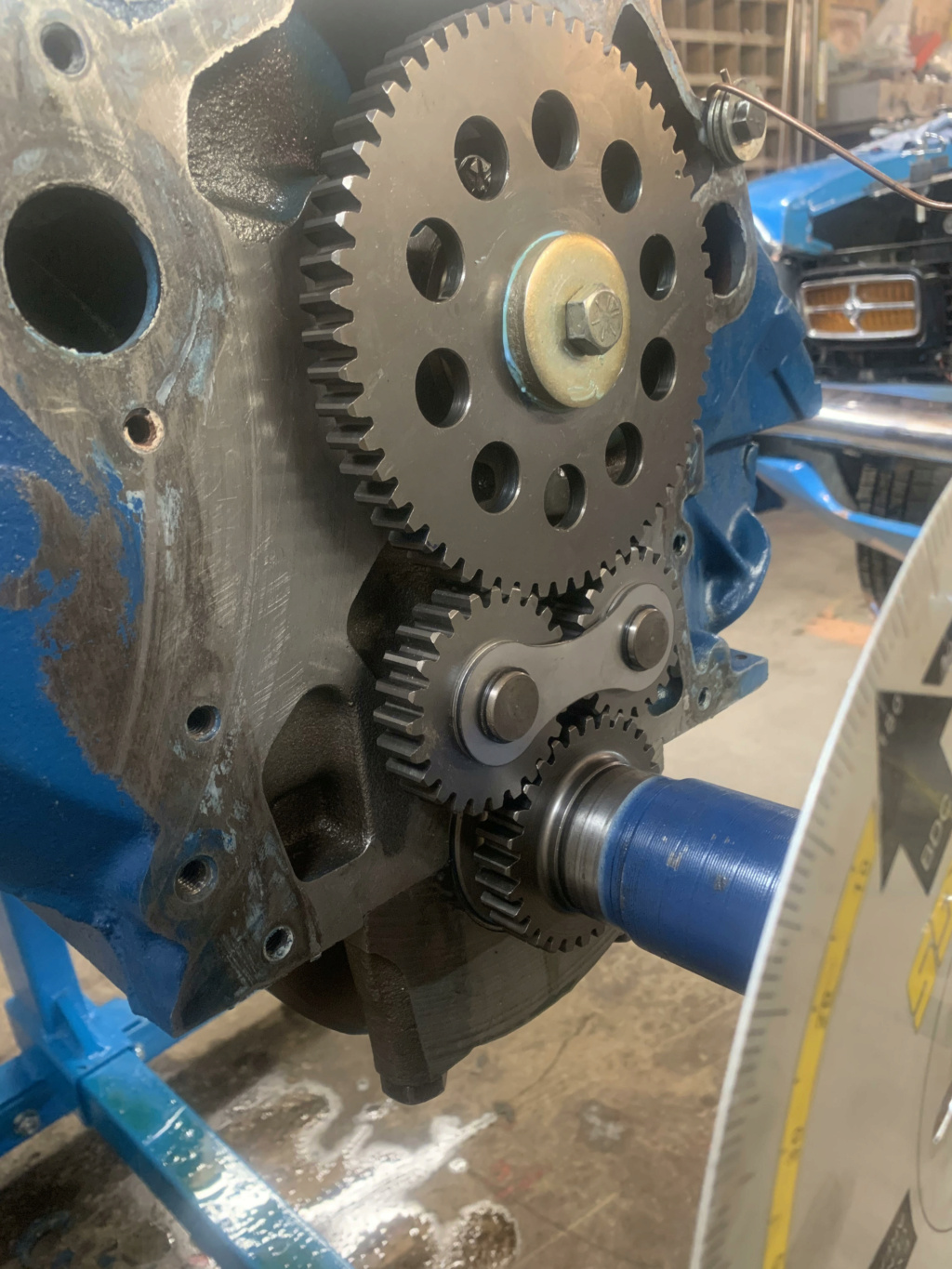

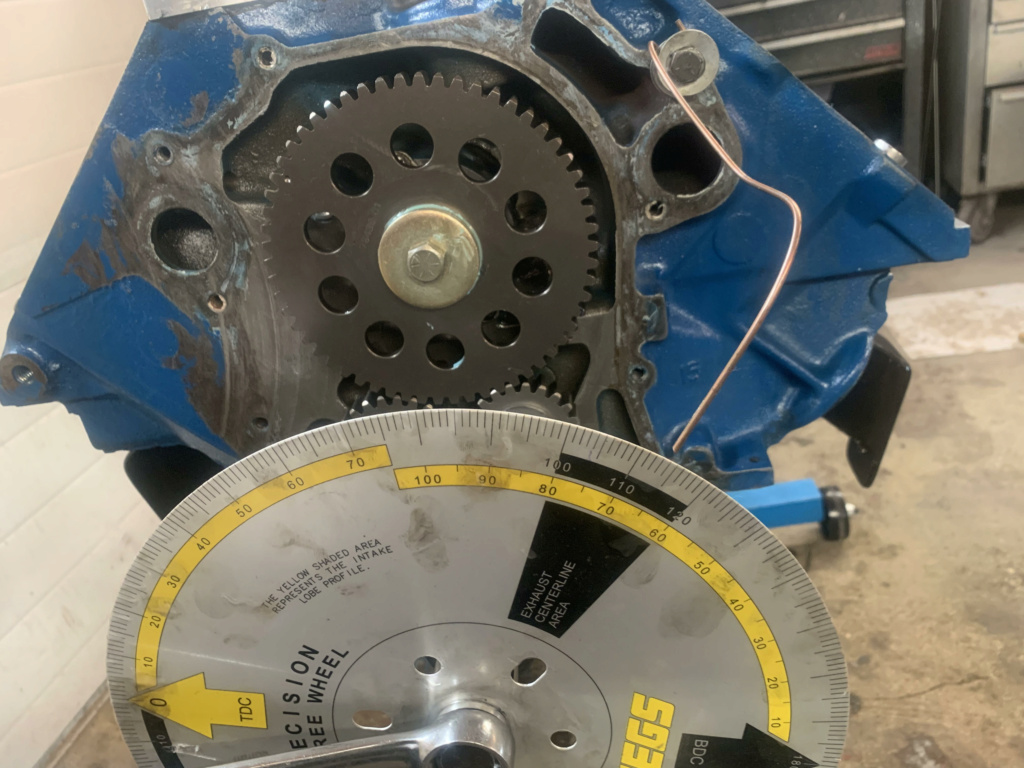

here is my exh and int centre line with my timing gears closest i could get was 5 degree with the set i have will this work or too advanced ?

i should not i could not double pin this timing gear set as it is hardened steel

but it is clearance fit on cam and using bigger washer . i torqued to 65# grade 8 7/16 bolt

i also locktighted the gear onto cam so it should help keep it in place i used blue so i could get apart with a puller.

maverick172- Posts : 205

Join date : 2022-10-16

Re: valve to cylinder bore/block clearance

Re: valve to cylinder bore/block clearance

why can i not turn the lifters so the hole faces the oil gallery channel would it not get way more oil to top end that way ?

supervel45 wrote:How are you checking the angle?

It might me best to put it away for the weekend, until you can talk to Kaase.

Like I said, don't rule out the offset dowl pins just yet. The valve angle and edge and all that help flow as well as heat on exhaust valves.

Did you check those plugs in the front of the block for depth, like Dave said?

maverick172- Posts : 205

Join date : 2022-10-16

Re: valve to cylinder bore/block clearance

Re: valve to cylinder bore/block clearance

maverick172 wrote:why can i not turn the lifters so the hole faces the oil gallery channel would it not get way more oil to top end that way ?

Yes, it would ... WAY too much oiling up top.

maverick172 likes this post

Re: valve to cylinder bore/block clearance

Re: valve to cylinder bore/block clearance

Put jour dial indicator on cylinder 1. Find the exact TDC. A piston stop in a spark plug hole is an easy method an very precise in my opinion. Just go back and forth until it hits and mark the degree wheel, them split it exactly in half by dividing the Total Degree's by 2 of the marks, on paper. Put the Split difference mark on the Degree Wheel. Repeat and double check, your Zero on your makeshift pointer Set your timing Pointer to Zero on your degree wheel and be careful not to move it after it is Zeroed! I might have mucked that up a little. Just make Sure TDC is EXACT.

Put a intake lifter in on cylinder 1 on the, and make sure it's on the intake lobe. Get the cam all the way on the bottom of the lobe. Be sure it is on the bottom.

Set your dial Indicator to Zero. Turn the engine in the direction it normally runs.

When you get to .050" lift stop. Your should see 27 on the Degree Wheel.

That should be a 109 ICL.

For 4 degree's advance you would be looking for 23 I believe and 61 closing at .050" on the Backside of the lobe.

Note I have been out in the sun working all day, so if I goofed, please forgive me as I don't degree cams all that often, and am going off of memory.

I am not going to say anything yet about your picture.

PS: If you advance that Cam, Be Sure and Re-Check your Intake Valve Piston to Valve Clearance and Radial Clearance in the Valve pocket!

Put a intake lifter in on cylinder 1 on the, and make sure it's on the intake lobe. Get the cam all the way on the bottom of the lobe. Be sure it is on the bottom.

Set your dial Indicator to Zero. Turn the engine in the direction it normally runs.

When you get to .050" lift stop. Your should see 27 on the Degree Wheel.

That should be a 109 ICL.

For 4 degree's advance you would be looking for 23 I believe and 61 closing at .050" on the Backside of the lobe.

Note I have been out in the sun working all day, so if I goofed, please forgive me as I don't degree cams all that often, and am going off of memory.

I am not going to say anything yet about your picture.

PS: If you advance that Cam, Be Sure and Re-Check your Intake Valve Piston to Valve Clearance and Radial Clearance in the Valve pocket!

Last edited by supervel45 on May 20th 2023, 10:23 pm; edited 1 time in total

supervel45- Posts : 4499

Join date : 2013-09-04

Re: valve to cylinder bore/block clearance

Re: valve to cylinder bore/block clearance

ya i know how to degree a cam.

my question was advanveing the cam 4 degree's with my timing set seems i can only get closer to 5 it only has a +2 -2 option so i just one full tooth and i got like 5 degree advance just wanting others to chim in on this combination what they think it will run like or just i just put it back to stright up?

and also useing a Timing "gear set " instead of a chain set i do not want to use a chain with that roller bearing on the back would like to find a chain without that that has the bronze thurst bearing . ? anyone got one ?

my question was advanveing the cam 4 degree's with my timing set seems i can only get closer to 5 it only has a +2 -2 option so i just one full tooth and i got like 5 degree advance just wanting others to chim in on this combination what they think it will run like or just i just put it back to stright up?

and also useing a Timing "gear set " instead of a chain set i do not want to use a chain with that roller bearing on the back would like to find a chain without that that has the bronze thurst bearing . ? anyone got one ?

supervel45 wrote:Put jour dial indicator on cylinder 1. Find the exact TDC. A piston stop in a spark plug hole is an easy method an very precise in my opinion. Just go back and forth until it hits and mark the degree wheel, them split it exactly in half by dividing the Total Degree's of the marks on paper. Put the Split difference mark on the Degree Wheel. Repeat and double check, your Zero on your makeshift pointer Set your timing Pointer to Zero on your degree wheel. I might have mucked that up a little. Just make Sure TDC is EXACT.

Put a intake lifter in on cylinder 1 on the, and make sure it's on the intake lobe. Get the cam all the way on the bottom of the lobe. Be sure it is on the bottom.

Set your dial Indicator to Zero. Turn the engine in the direction it normally runs.

When you get to .050" lift stop. Your should see 27 on the Degree Wheel.

That should be a 109 ICL.

For 4 degree's advance you would be looking for 23 I believe.

Note I have been out in the sun working all day, so if I goofed, please forgive me as I don't degree cams all that often, and am going off of memory.

I am not going to say anything yet about your picture.

maverick172- Posts : 205

Join date : 2022-10-16

Re: valve to cylinder bore/block clearance

Re: valve to cylinder bore/block clearance

I am just double checking on your Degreeing. I did not see that picture good at first, I am used to Intake Degreeing. You are on the Exhaust. The picture clipped the other side.

I think it would be better advanced with 104 ICL which is 5 degree's, do to the Lowish Compression and Big Cam. That's the Number Paul Kane Gave you at the other sight.

I mentioned 105 as I thought you had a 4 degree keyed timing set set and it easy and not worth one degree and maybe Paul Misstyped by 1 degree on the Fly.

I think it would be better advanced with 104 ICL which is 5 degree's, do to the Lowish Compression and Big Cam. That's the Number Paul Kane Gave you at the other sight.

I mentioned 105 as I thought you had a 4 degree keyed timing set set and it easy and not worth one degree and maybe Paul Misstyped by 1 degree on the Fly.

supervel45- Posts : 4499

Join date : 2013-09-04

maverick172 likes this post

Re: valve to cylinder bore/block clearance

Re: valve to cylinder bore/block clearance

maverick172 wrote:ya i know how to degree a cam.

my question was advanveing the cam 4 degree's with my timing set seems i can only get closer to 5 it only has a +2 -2 option so i just one full tooth and i got like 5 degree advance just wanting others to chim in on this combination what they think it will run like or just i just put it back to stright up?

and also useing a Timing "gear set " instead of a chain set i do not want to use a chain with that roller bearing on the back would like to find a chain without that that has the bronze thurst bearing . ? anyone got one ?supervel45 wrote:Put jour dial indicator on cylinder 1. Find the exact TDC. A piston stop in a spark plug hole is an easy method an very precise in my opinion. Just go back and forth until it hits and mark the degree wheel, them split it exactly in half by dividing the Total Degree's of the marks on paper. Put the Split difference mark on the Degree Wheel. Repeat and double check, your Zero on your makeshift pointer Set your timing Pointer to Zero on your degree wheel. I might have mucked that up a little. Just make Sure TDC is EXACT.

Put a intake lifter in on cylinder 1 on the, and make sure it's on the intake lobe. Get the cam all the way on the bottom of the lobe. Be sure it is on the bottom.

Set your dial Indicator to Zero. Turn the engine in the direction it normally runs.

When you get to .050" lift stop. Your should see 27 on the Degree Wheel.

That should be a 109 ICL.

For 4 degree's advance you would be looking for 23 I believe.

Note I have been out in the sun working all day, so if I goofed, please forgive me as I don't degree cams all that often, and am going off of memory.

I am not going to say anything yet about your picture.

Something dawned on me. I have never before seen a 3 keyway crank shaft timing sprocket in my life that was not 0 -4 or +4.. EXCEPT

I know this (below)for a fact and even started a thread on it on CompCams roller timing sets.

The High Engergy set has 4 or more degrees retard on what looks to be marked 0 on the gear. I think the retard keyway maybe -8.

Not likely the case on yours but, It was Odd that it would be 2 Degrees (Increments).

It has to do with the factory Smog engines that Ford retarded the camshafts in, during 1970's for the 1972 for Emissions requirements.

The Magnum Timing set has a True Zero with the Keyway Directly in Line with the Tooth on the Gear.

Also make sure you Idler gear on that gear drive has the big gear correctly installed on the correct side of the block.

Also make sure the pins on the block side or free to move up and down and can't bind. I don't know if that is a problem with a 460 but it is with other engines. I had to cut my Pete Jackson pins to accomplish that, per instructions.

If that is green Loctite behind that cam washer, I would be very Leary of That. I use Red on the bolt just because. I would be worried about Heat and also it not Clamping as Well and Potential Shinkage down the Road on the Washer, then Steel to Steel.

That's just me and I have newer heard of anybody else doing that either. I just would not gamble that.

supervel45- Posts : 4499

Join date : 2013-09-04

maverick172 likes this post

Re: valve to cylinder bore/block clearance

Re: valve to cylinder bore/block clearance

supervel45 wrote:

Something dawned on me. I have never before seen a 3 keyway crank shaft timing sprocket in my life that was not 0 -4 or +4.. .

You need to be very careful there ...some which are labeled like that are in "camshaft" degrees not "crankshaft" degrees.

Re: valve to cylinder bore/block clearance

Re: valve to cylinder bore/block clearance

No Doubt Randy. They don't make it too easy on with Fords sometimes. Not saying it's not the same with other makes timing gears.

Here is a picture of a 8 camshaft degree Retard 429/460 Smogger crankshaft timing gear for anyone else who comes across this thread later.

You can see how much the 8 camshaft degree retard keyway cut, is off from the tooth. Pictures curtsy of Reincarnation Mad Porter.

https://www.460ford.com/threads/crank-timing-gear-3-key-ways.225082/#lg=thread-225082&slide=1

A regular 3 keyway -4 0 +4 camshaft degrees gear for reference.

https://www.460ford.com/threads/same-old-timing-chain-advance-retard-keyway-question.187065/#lg=thread-187065&slide=0

Here is a picture of a 8 camshaft degree Retard 429/460 Smogger crankshaft timing gear for anyone else who comes across this thread later.

You can see how much the 8 camshaft degree retard keyway cut, is off from the tooth. Pictures curtsy of Reincarnation Mad Porter.

https://www.460ford.com/threads/crank-timing-gear-3-key-ways.225082/#lg=thread-225082&slide=1

A regular 3 keyway -4 0 +4 camshaft degrees gear for reference.

https://www.460ford.com/threads/same-old-timing-chain-advance-retard-keyway-question.187065/#lg=thread-187065&slide=0

supervel45- Posts : 4499

Join date : 2013-09-04

Similar topics

Similar topics» Cometic 4.400 bore gaskets on 4.390 bore block ,will it work ?

» block max. bore

» how much is a 1972 429 4bolt cobra jet block worth.. Just the block and main caps.??? std bore

» cylinder bore

» 540 Long block / Boss9 block / AR CJ cylinder heads - $3300 OBO

» block max. bore

» how much is a 1972 429 4bolt cobra jet block worth.. Just the block and main caps.??? std bore

» cylinder bore

» 540 Long block / Boss9 block / AR CJ cylinder heads - $3300 OBO

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum