New 523 Project Component Selection Questions

+7

cletus66

Lem Evans

Dave De

jasonf

dfree383

rmcomprandy

Athlonia

11 posters

Page 1 of 1

New 523 Project Component Selection Questions

New 523 Project Component Selection Questions

Hello All,

I will start off by saying that I am still learning and this is my first BBF build.

I purchased someones incomplete engine build and will list the components I received with my purchase. All parts are brand new and have never been run. What I would like to know is what I need to change to meet my goals before assembling the engine. I realize that many of the components are overkill for my goals, but it was a deal I could not pass up.

Goals: A streetable 523 that will go in my 1973 Mustang Fastback. The care weighs about 3400 lbs. I would like to have 600 or more hp on 87 octane. Before I get blasted for my fuel requirement, it is not driven by money, it is driven by the crappy fuel (and will only get worse) in my area and the desire to be able to fill it up anywhere. I will be running a G-Force TR3650 5 speed transmission, the rear end gear is not selected yet as I do not have my rear tires selected and will match the gear to meet the engine needs. The car has AC and I am planning to run FITech EFI and cruise control. Feel free to let me know if you see an issue with my goals or other detail I omitted.

Current hardware I receive with my purchase: Forged Scat 4.3 crankshaft, 6.8 H beam Scat rods, custom Diamond pistons with a 26cc dish, fully machined block with a 4.400 bore, pistons are 0.010 in the hole, Kaase P51 heads with hydraulic roller springs (new untouched heads), hydraulic roller camshaft from Kaase . Trickflow Mafia Dominator intake manifold, Kaase oil pump, Innovation West damper, full ARP studs for mains and heads. The current static compression ratio is 10.6.

. Trickflow Mafia Dominator intake manifold, Kaase oil pump, Innovation West damper, full ARP studs for mains and heads. The current static compression ratio is 10.6.

The previous owner was planning to run 89 octane, but I want to validate with the experts on here if it is a sound build plan. If it is not, what would you recommend I change?

Thank you in advance.

I will start off by saying that I am still learning and this is my first BBF build.

I purchased someones incomplete engine build and will list the components I received with my purchase. All parts are brand new and have never been run. What I would like to know is what I need to change to meet my goals before assembling the engine. I realize that many of the components are overkill for my goals, but it was a deal I could not pass up.

Goals: A streetable 523 that will go in my 1973 Mustang Fastback. The care weighs about 3400 lbs. I would like to have 600 or more hp on 87 octane. Before I get blasted for my fuel requirement, it is not driven by money, it is driven by the crappy fuel (and will only get worse) in my area and the desire to be able to fill it up anywhere. I will be running a G-Force TR3650 5 speed transmission, the rear end gear is not selected yet as I do not have my rear tires selected and will match the gear to meet the engine needs. The car has AC and I am planning to run FITech EFI and cruise control. Feel free to let me know if you see an issue with my goals or other detail I omitted.

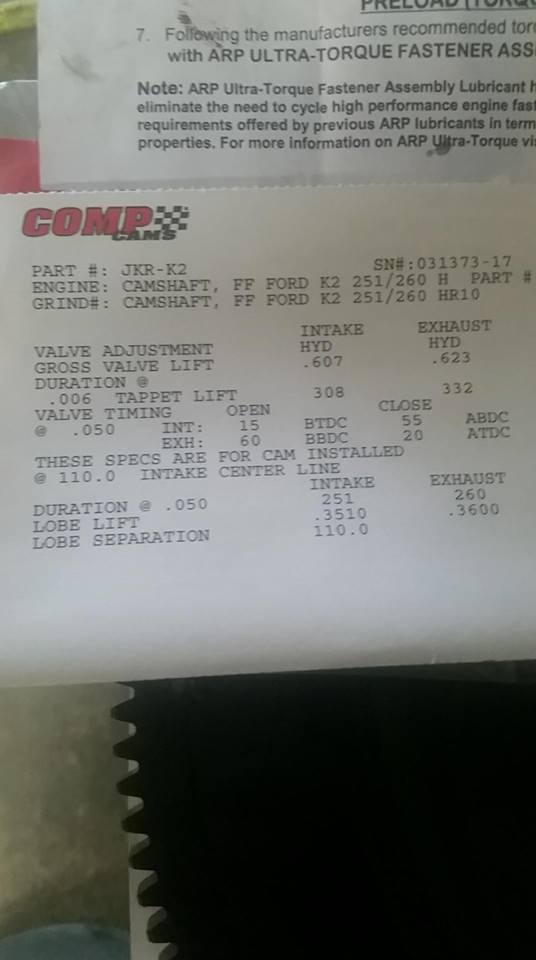

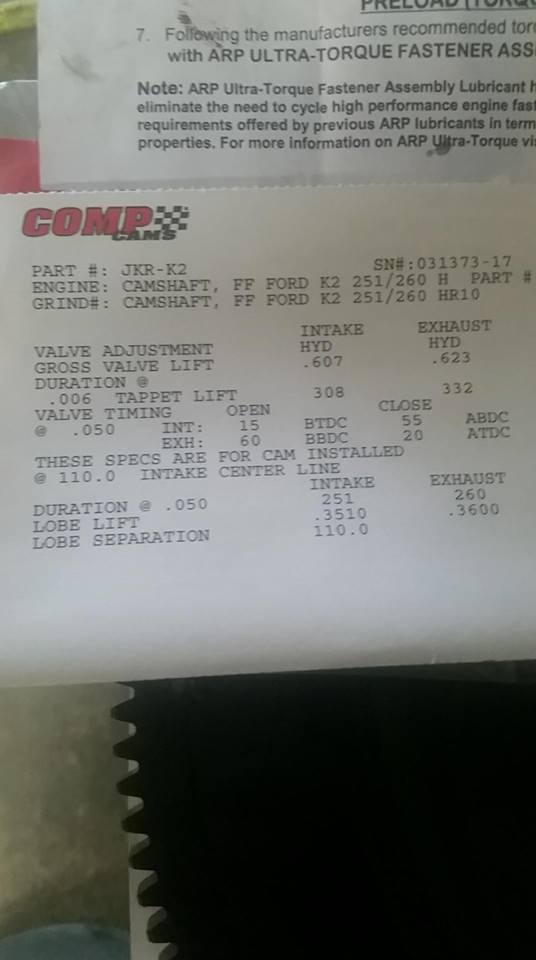

Current hardware I receive with my purchase: Forged Scat 4.3 crankshaft, 6.8 H beam Scat rods, custom Diamond pistons with a 26cc dish, fully machined block with a 4.400 bore, pistons are 0.010 in the hole, Kaase P51 heads with hydraulic roller springs (new untouched heads), hydraulic roller camshaft from Kaase

. Trickflow Mafia Dominator intake manifold, Kaase oil pump, Innovation West damper, full ARP studs for mains and heads. The current static compression ratio is 10.6.

. Trickflow Mafia Dominator intake manifold, Kaase oil pump, Innovation West damper, full ARP studs for mains and heads. The current static compression ratio is 10.6.The previous owner was planning to run 89 octane, but I want to validate with the experts on here if it is a sound build plan. If it is not, what would you recommend I change?

Thank you in advance.

Athlonia- Posts : 21

Join date : 2013-06-15

Age : 52

Location : Central Iowa

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

Have the piston crowns "step cut" for more cc volume to about 40 cc's.

A 10.6/1 compression high performance engine, (which you now have), will have a difficult time running 87 octane gasoline at normal street type running temperatures; even with a big cam.

A 10.6/1 compression high performance engine, (which you now have), will have a difficult time running 87 octane gasoline at normal street type running temperatures; even with a big cam.

Thank you

Thank you

rmcomprandy wrote:Have the piston crowns "step cut" for more cc volume to about 40 cc's.

A 10.6/1 compression high performance engine, (which you now have), will have a difficult time running 87 octane gasoline at normal street type running temperatures; even with a big cam.

Thank you. Would you run the camshaft I currently have with the deeper dish piston? If I take the dish to about 40cc, that should yield about 9.5, correct?

Athlonia- Posts : 21

Join date : 2013-06-15

Age : 52

Location : Central Iowa

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

I’d do a mild port job on the heads and with your octane constraint is definetly follow what Randy said. May want to consider some custom cam timing and some piston / combustion chamber coating

dfree383- BBF CONTRIBUTOR

- Posts : 14851

Join date : 2009-07-09

Location : Home Wif Da Wife.....

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

dfree383 wrote:I’d do a mild port job on the heads and with your octane constraint is definetly follow what Randy said. May want to consider some custom cam timing and some piston / combustion chamber coating

Why would he port the heads? He said he wants over 600 HP...stuff he has should make over 700 hp as is.

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

Where do you live that they only have 87 octane fuel? You are going to spend tens of thousands of dollars building a nice car and you are going to build it around the cheapest fuel you can find?

jasonf- BBF CONTRIBUTOR

- Posts : 2994

Join date : 2009-07-14

Age : 55

Location : Lafayette, LA

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

jasonf wrote:Where do you live that they only have 87 octane fuel? You are going to spend tens of thousands of dollars building a nice car and you are going to build it around the cheapest fuel you can find?

I live in central Iowa. I didn't not say that 87 octane is all that you can find here, but anything above 87 is getting more difficult. For example, both Kwik Stars in my area recently switched their pumps to 87 only. And as I stated in my original post, the fuel requirement is not a money driven goal, it is purely a convenience goal. I don't know why that is hard for people to understand. I do not want to worry about where I need to fill up, I am not after maximum hp from my engine, I want a solid reliable, fun to drive ride with more than enough hp to get me in trouble. Is 600 hp a reasonable goal on 87 octane with the cubes and heads that I have? Thank you for your question.

Athlonia- Posts : 21

Join date : 2013-06-15

Age : 52

Location : Central Iowa

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

Lem Evans wrote:dfree383 wrote:I’d do a mild port job on the heads and with your octane constraint is definetly follow what Randy said. May want to consider some custom cam timing and some piston / combustion chamber coating

Why would he port the heads? He said he wants over 600 HP...stuff he has should make over 700 hp as is.

Lem, would you suggest running the camshaft I currently have if I have the piston dish enlarged and get the static compression in the 9.5:1 range? I am open to changing whatever parts I need to in order to have an efficient and planned engine. Thank you.

Athlonia- Posts : 21

Join date : 2013-06-15

Age : 52

Location : Central Iowa

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

Lem Evans wrote:dfree383 wrote:I’d do a mild port job on the heads and with your octane constraint is definetly follow what Randy said. May want to consider some custom cam timing and some piston / combustion chamber coating

Why would he port the heads? He said he wants over 600 HP...stuff he has should make over 700 hp as is.

With the lower compression and less than optimal cam timing it will make things easer. He ain’t running premium fuel and wants a bunch of power

dfree383- BBF CONTRIBUTOR

- Posts : 14851

Join date : 2009-07-09

Location : Home Wif Da Wife.....

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

Athlonia wrote:rmcomprandy wrote:Have the piston crowns "step cut" for more cc volume to about 40 cc's.

A 10.6/1 compression high performance engine, (which you now have), will have a difficult time running 87 octane gasoline at normal street type running temperatures; even with a big cam.

Thank you. Would you run the camshaft I currently have with the deeper dish piston? If I take the dish to about 40cc, that should yield about 9.5, correct?

Personally, I would not run a Hydraulic roller set-up in a street engine with the engine having a stud type valve train. It's done often however, I would pay close attention to the valve guide clearances.

The cam is about the right size though.

Last edited by rmcomprandy on June 3rd 2018, 10:01 am; edited 1 time in total

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

rmcomprandy wrote:Athlonia wrote:rmcomprandy wrote:Have the piston crowns "step cut" for more cc volume to about 40 cc's.

A 10.6/1 compression high performance engine, (which you now have), will have a difficult time running 87 octane gasoline at normal street type running temperatures; even with a big cam.

Thank you. Would you run the camshaft I currently have with the deeper dish piston? If I take the dish to about 40cc, that should yield about 9.5, correct?

Personally, I would not run a Hydraulic roller set-up on a street engine with an engine having a stud type valve train. It's done often however, I would pay close attention to the valve guide clearances.

Thanks, how about from a cam profile perspective?

Athlonia- Posts : 21

Join date : 2013-06-15

Age : 52

Location : Central Iowa

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

Going back to the 87 octane decision.

Are you aware that in a few years the lowest grade will likely be 95 octane? That being the case do you still want to drop the compression all that way to build around 87 octane?

http://wardsauto.com/engines/automakers-pitch-higher-octane-future

https://www.autoblog.com/2018/02/11/premium-91-octane-gas-fuel-economy/

This is necessary to meet the CAFE goals in 2025 that are at 50mpg.

Just looking forward, if I was you I'd make it set on the ragged edge for 93 octane and do a little de-tuning until the good stuff arrives. Aside from that, low compression, big cam builds equal an obnoxious exhaust smell that permeates your clothes. This is not street car friendly but EFI will help.

Considering that you live in Iowa I am surprised that you dont step up to E85 that allows you to raise the compression above 13. If you did that you could run a SFT cam and still make more power while reducing the cost of the build.

Are you aware that in a few years the lowest grade will likely be 95 octane? That being the case do you still want to drop the compression all that way to build around 87 octane?

http://wardsauto.com/engines/automakers-pitch-higher-octane-future

https://www.autoblog.com/2018/02/11/premium-91-octane-gas-fuel-economy/

This is necessary to meet the CAFE goals in 2025 that are at 50mpg.

Just looking forward, if I was you I'd make it set on the ragged edge for 93 octane and do a little de-tuning until the good stuff arrives. Aside from that, low compression, big cam builds equal an obnoxious exhaust smell that permeates your clothes. This is not street car friendly but EFI will help.

Considering that you live in Iowa I am surprised that you dont step up to E85 that allows you to raise the compression above 13. If you did that you could run a SFT cam and still make more power while reducing the cost of the build.

Dave De- Posts : 797

Join date : 2011-05-27

Location : Highland, MI

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

dfree383 wrote:Lem Evans wrote:dfree383 wrote:I’d do a mild port job on the heads and with your octane constraint is definetly follow what Randy said. May want to consider some custom cam timing and some piston / combustion chamber coating

Why would he port the heads? He said he wants over 600 HP...stuff he has should make over 700 hp as is.

With the lower compression and less than optimal cam timing it will make things easer. He ain’t running premium fuel and wants a bunch of power

Dillon's 528" boat engine made 707 @ 5,900 rpm. 10.0/1...not 10.7/1....actual measured 10.0/1.

Unported SCJs with back cut intake valves and unported Victor intake [Freelander reject :-}]. He's got a better head with a bigger intake valve and a lot better intake manifold so, if his engine has 1/2-2/3 point less compression ratio it should still make the same or more power as Robert's jetboat engine.

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

Lem Evans wrote:dfree383 wrote:Lem Evans wrote:dfree383 wrote:I’d do a mild port job on the heads and with your octane constraint is definetly follow what Randy said. May want to consider some custom cam timing and some piston / combustion chamber coating

Why would he port the heads? He said he wants over 600 HP...stuff he has should make over 700 hp as is.

With the lower compression and less than optimal cam timing it will make things easer. He ain’t running premium fuel and wants a bunch of power

Dillon's 528" boat engine made 707 @ 5,900 rpm. 10.0/1...not 10.7/1....actual measured 10.0/1.

Unported SCJs with back cut intake valves and unported Victor intake [Freelander reject :-}]. He's got a better head with a bigger intake valve and a lot better intake manifold so, if his engine has 1/2-2/3 point less compression ratio it should still make the same or more power as Robert's jetboat engine.

What kinda cam in that thing?

cletus66- Posts : 865

Join date : 2009-08-08

Age : 58

Location : Charles City, Virginia

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

cletus66 wrote:Lem Evans wrote:dfree383 wrote:Lem Evans wrote:dfree383 wrote:I’d do a mild port job on the heads and with your octane constraint is definetly follow what Randy said. May want to consider some custom cam timing and some piston / combustion chamber coating

Why would he port the heads? He said he wants over 600 HP...stuff he has should make over 700 hp as is.

With the lower compression and less than optimal cam timing it will make things easer. He ain’t running premium fuel and wants a bunch of power

Dillon's 528" boat engine made 707 @ 5,900 rpm. 10.0/1...not 10.7/1....actual measured 10.0/1.

Unported SCJs with back cut intake valves and unported Victor intake [Freelander reject :-}]. He's got a better head with a bigger intake valve and a lot better intake manifold so, if his engine has 1/2-2/3 point less compression ratio it should still make the same or more power as Robert's jetboat engine.

What kinda cam in that thing?

Custom deal I did. 260*/270* @.050"...not big at all. Solid lifter roller style.

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

Lem Evans wrote:cletus66 wrote:Lem Evans wrote:dfree383 wrote:Lem Evans wrote:dfree383 wrote:I’d do a mild port job on the heads and with your octane constraint is definetly follow what Randy said. May want to consider some custom cam timing and some piston / combustion chamber coating

Why would he port the heads? He said he wants over 600 HP...stuff he has should make over 700 hp as is.

With the lower compression and less than optimal cam timing it will make things easer. He ain’t running premium fuel and wants a bunch of power

Dillon's 528" boat engine made 707 @ 5,900 rpm. 10.0/1...not 10.7/1....actual measured 10.0/1.

Unported SCJs with back cut intake valves and unported Victor intake [Freelander reject :-}]. He's got a better head with a bigger intake valve and a lot better intake manifold so, if his engine has 1/2-2/3 point less compression ratio it should still make the same or more power as Robert's jetboat engine.

What kinda cam in that thing?

Custom deal I did. 260*/270* @.050"...not big at all. Solid lifter roller style.

Thanks.

cletus66- Posts : 865

Join date : 2009-08-08

Age : 58

Location : Charles City, Virginia

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

rmcomprandy wrote:Athlonia wrote:rmcomprandy wrote:Have the piston crowns "step cut" for more cc volume to about 40 cc's.

A 10.6/1 compression high performance engine, (which you now have), will have a difficult time running 87 octane gasoline at normal street type running temperatures; even with a big cam.

Thank you. Would you run the camshaft I currently have with the deeper dish piston? If I take the dish to about 40cc, that should yield about 9.5, correct?

Personally, I would not run a Hydraulic roller set-up in a street engine with the engine having a stud type valve train. It's done often however, I would pay close attention to the valve guide clearances.

The cam is about the right size though.

Can someone elaborate about the hydraulic roller set up statement please? Would like to understand.

Axshun- Posts : 20

Join date : 2018-10-02

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

The higher pushrod seat placement in the hydraulic roller lifter increases "sideways" motion in the rocker due to the increase in angularity on a stud mounted application. That is why Randy specified "stud mounted" in his post. Obviously when the roller tip is supposed to be reducing friction , twisting it sideways while rolling ADDS drag and wears the guide like we are trying to avoid. It's really an issue on canted valve engines of any make. Use of a shaft mounted rocker limits the twisting motion because the shaft won't allow the rocker body to twist and "take out" the valve guide. The side loading it still present but the pushrod seat in the rocker is able to handle it. However there does seem to be an increase in rocker breakage in the pushrod side. Super high valve spring pressures are the likely reason but a twisting motion certainly wouldn't help.

gt350hr- Posts : 662

Join date : 2014-08-20

Location : Anaheim , CA

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

That makes sense. Is the shaft mounted rocker something that the head has to be machined for, or is there a way to mount it onto P51 heads?

Axshun- Posts : 20

Join date : 2018-10-02

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

And this situation would be worse on a big block Chevy because of its lower deck height, which puts the pushrods in even more of an angle.gt350hr wrote:The higher pushrod seat placement in the hydraulic roller lifter increases "sideways" motion in the rocker due to the increase in angularity on a stud mounted application. That is why Randy specified "stud mounted" in his post. Obviously when the roller tip is supposed to be reducing friction , twisting it sideways while rolling ADDS drag and wears the guide like we are trying to avoid. It's really an issue on canted valve engines of any make. Use of a shaft mounted rocker limits the twisting motion because the shaft won't allow the rocker body to twist and "take out" the valve guide. The side loading it still present but the pushrod seat in the rocker is able to handle it. However there does seem to be an increase in rocker breakage in the pushrod side. Super high valve spring pressures are the likely reason but a twisting motion certainly wouldn't help.

BBFTorino- Posts : 999

Join date : 2015-12-31

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

Before you commit to anything, measure the deck on your pistons. You don't even know if you have the material to cut the dishes.

Mark O'Neal- Posts : 286

Join date : 2009-08-12

Re: New 523 Project Component Selection Questions

Re: New 523 Project Component Selection Questions

BBFTorino wrote:And this situation would be worse on a big block Chevy because of its lower deck height, which puts the pushrods in even more of an angle.gt350hr wrote:The higher pushrod seat placement in the hydraulic roller lifter increases "sideways" motion in the rocker due to the increase in angularity on a stud mounted application. That is why Randy specified "stud mounted" in his post. Obviously when the roller tip is supposed to be reducing friction , twisting it sideways while rolling ADDS drag and wears the guide like we are trying to avoid. It's really an issue on canted valve engines of any make. Use of a shaft mounted rocker limits the twisting motion because the shaft won't allow the rocker body to twist and "take out" the valve guide. The side loading it still present but the pushrod seat in the rocker is able to handle it. However there does seem to be an increase in rocker breakage in the pushrod side. Super high valve spring pressures are the likely reason but a twisting motion certainly wouldn't help.

A BBC has staggered lifter bores which help angularity changes "some" , but they also have a large difference in pushrod length along with a steeper valve angle that hurts . Ford lifter bores are in line and have greater angularity to begin with.

gt350hr- Posts : 662

Join date : 2014-08-20

Location : Anaheim , CA

Similar topics

Similar topics» Cam selection

» Cam selection help

» Need cam selection advice

» NEED HELP cam shaft selection

» cam and intake selection for a 429

» Cam selection help

» Need cam selection advice

» NEED HELP cam shaft selection

» cam and intake selection for a 429

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum